Single motor hybrid automobile power drive mechanism based on planetary gear train

A technology of hybrid electric vehicles and driving mechanisms, which is applied to the layout of multiple different prime movers, power devices, and air pressure power devices of general power devices, and can solve difficulties, restrictions on the selection of engine operating points, and increased engine operating states, etc. problem, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

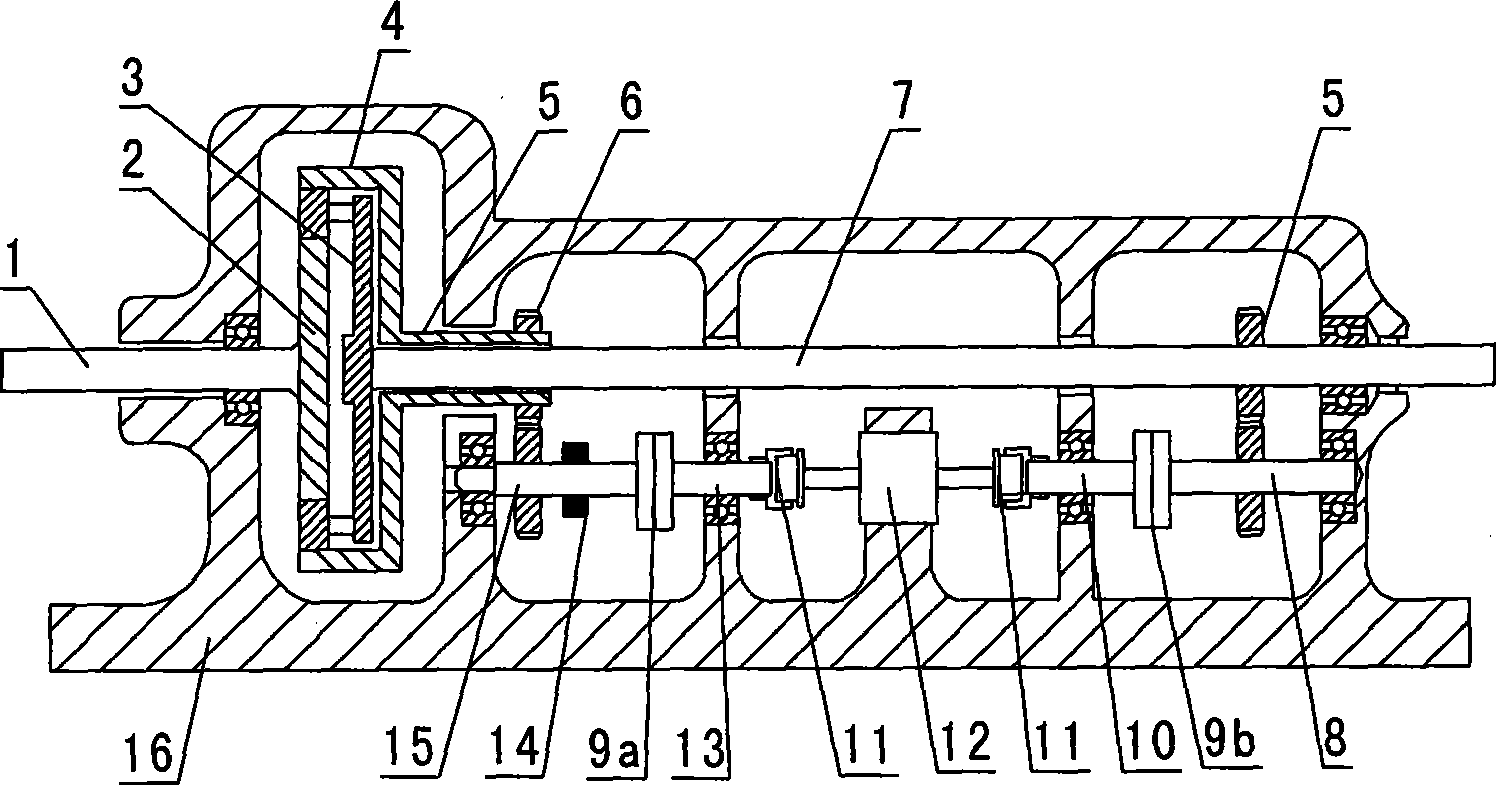

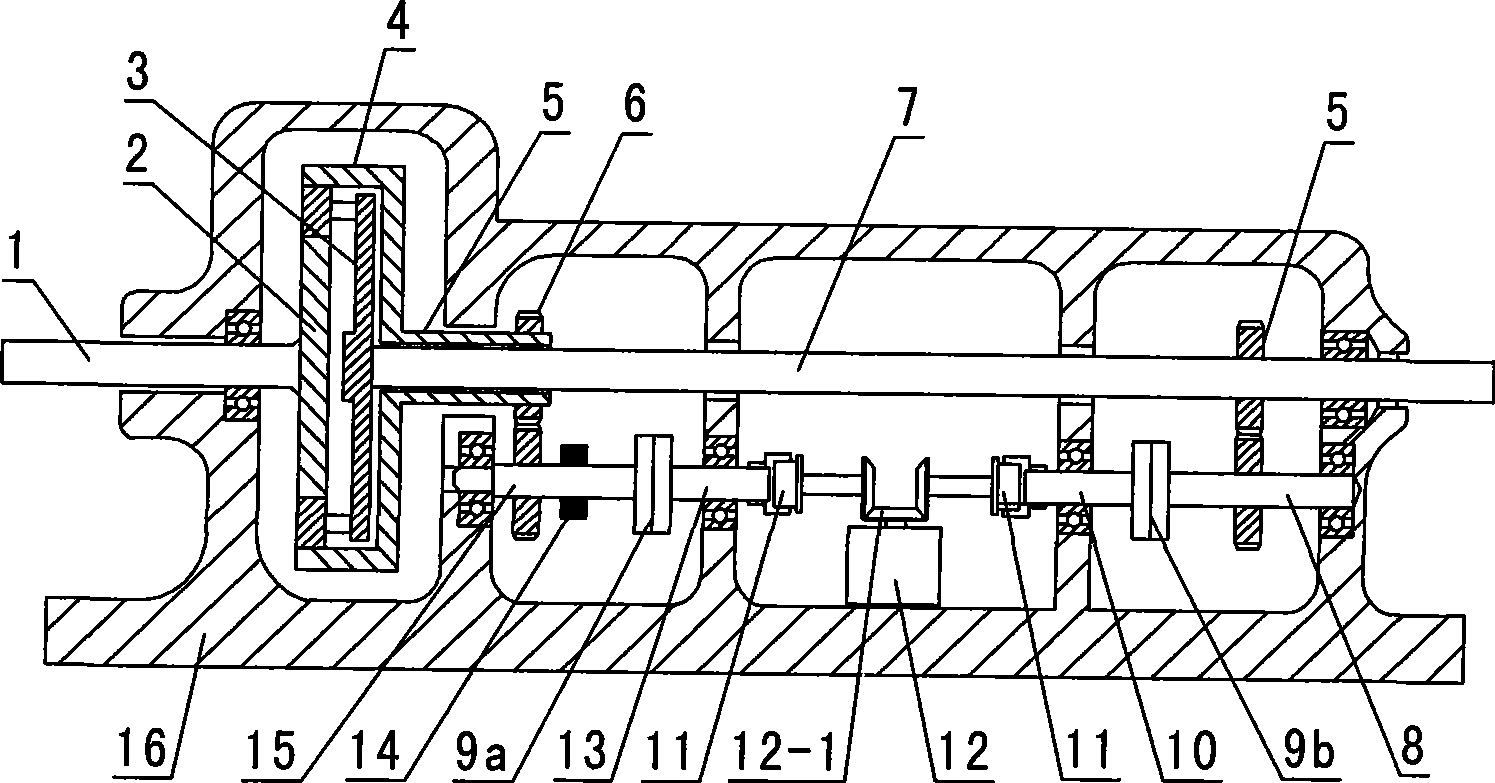

[0027] Such as figure 1 In the shown embodiment 1, the motor 12 of the planetary gear train and the double-ended shaft is arranged in the body 16 . The sun gear 2 of the planetary gear system is provided with a sun gear central shaft 1, and its shaft end can be connected to the output shaft of a power source including a reciprocating piston engine, a rotary engine, a gas turbine, a steam engine and the like via an existing deceleration or speed-up mechanism.

[0028] The planet carrier 3 of the planetary gear train is connected with the power output shaft 7 of the drive mechanism, and the power output shaft 7 is connected with a transmission (not shown) in the prior art.

[0029] The ring gear 4 of the planetary gear train is provided with a hollow shaft 5 sleeved on the power output shaft 7 , and the hollow shaft 5 is provided with a gear pair 6 connected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com