Sieve tube well completion method under insufficient balance condition and temporary blocking type sieve tube

A screen completion and underbalanced technology, which is applied in the field of oil drilling and cementing, can solve problems such as the complexity of expansion tools, and achieve the effects of avoiding pollution, protecting production layers, and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

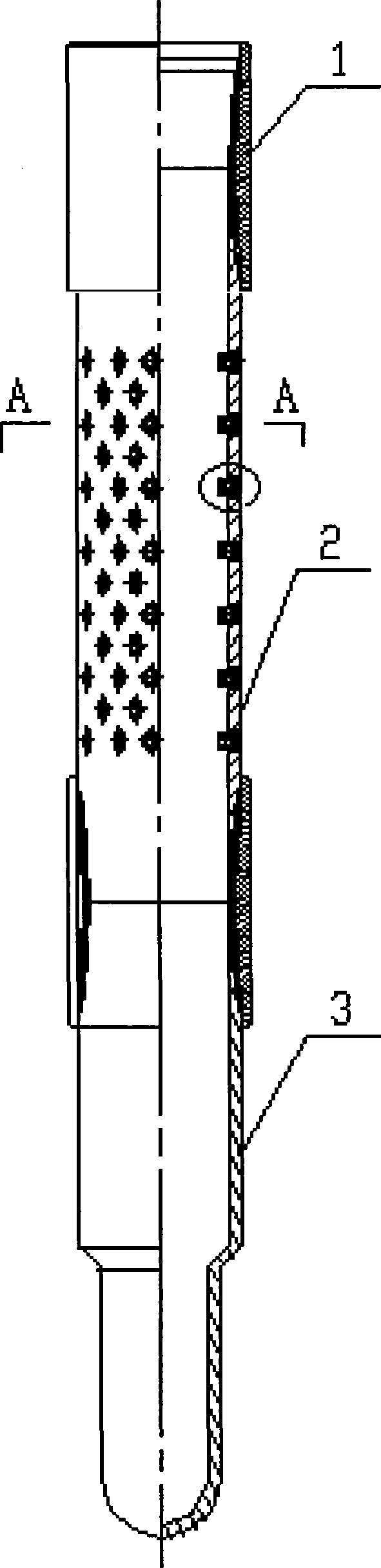

[0025] Embodiment 1: With a 5000-meter-deep oil well that adopts the underbalanced drilling method to complete, the well section above 3500 meters has 7 "technical casing cementing. It is necessary to lower a section of 100-meter-long 5 " temporary drilling at the lowermost end of the oil well. Taking the plugged screen as an example, the screen completion method under the under-balanced condition is further described in detail.

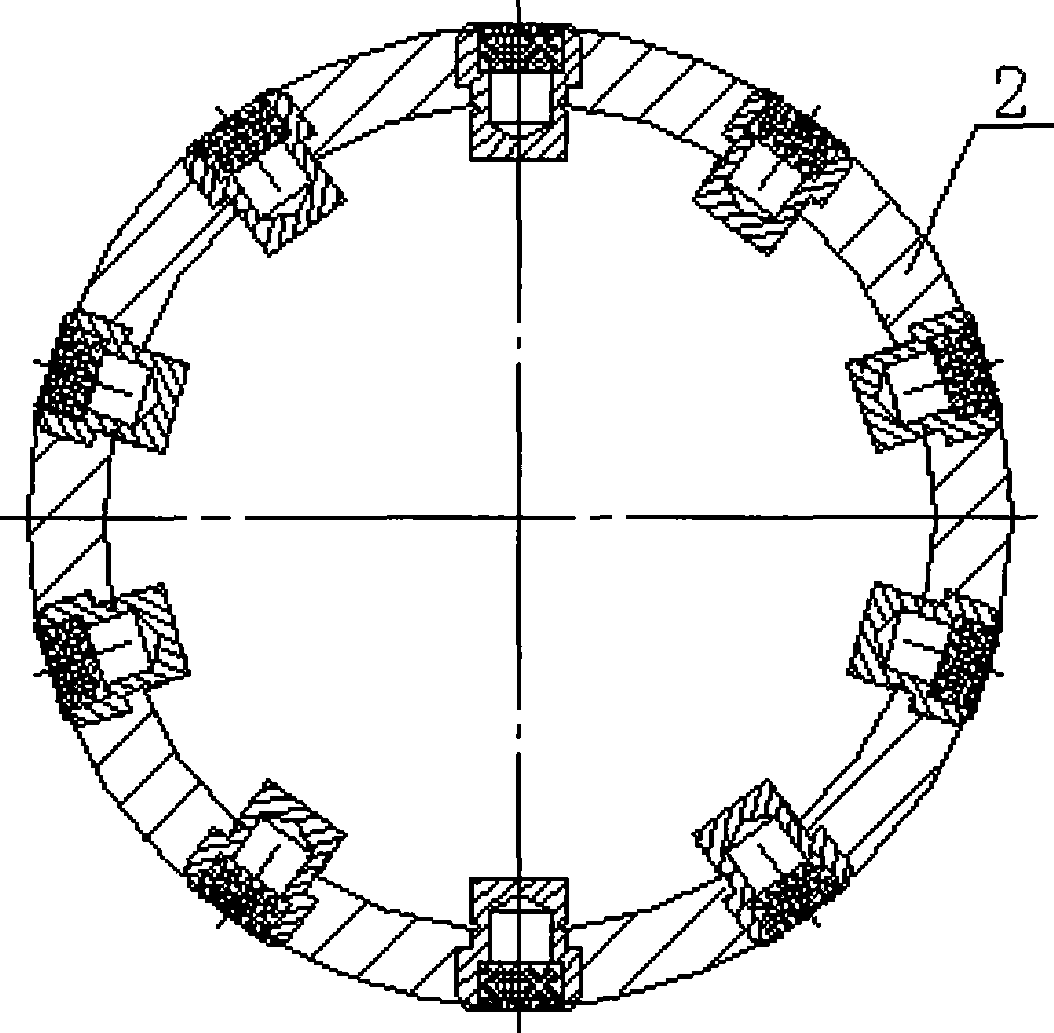

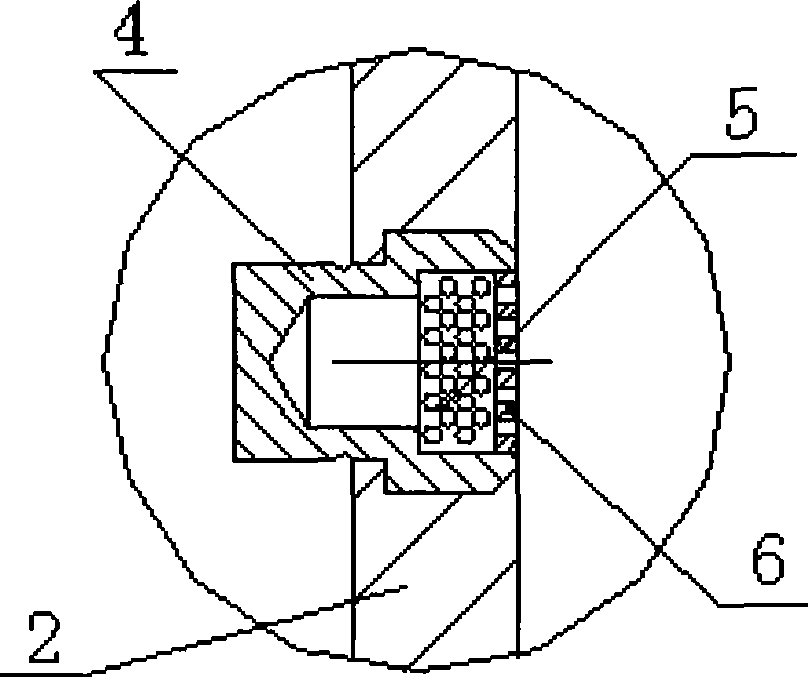

[0026] Connect the guide shoe 3 with the 5″ temporary plugging screen with coupling 1, the upper part of the temporary plugging screen is 100 meters long, the upper part of the temporary plugging screen is connected to the liner hanger, and the upper part of the liner hanger is connected to the drill pipe. During the process, the plugging of the temporary plugging screen can seal off the pressure in the well, so that the mud cannot enter the temporary plugging screen, so as to achieve underbalanced running.Refer to figure 1 . The base pipe 2 of each...

Embodiment 2

[0030] Embodiment 2: Embodiment 2 is basically the same as Embodiment 1. The difference is: when the casing string is lowered into the wellbore, the top of the casing is connected to the liner hanger, and the casing string with the temporary plugging screen is suspended on the inner wall of the upper layer of casing by the liner hanger . The specific difference is: when the connecting length of the lower casing string reaches 1500 meters, the upper part is connected with a 7″×5″ liner hanger. The upper part of the 7″×5″ liner hanger connects the drill pipe all the way to the wellhead. Use the drill pipe to hang the liner hanger on the inner wall of the lower end of the 7" technical casing. The process and method of liner hanger have been used for decades and can be completed by those skilled in the art, and will not be described in detail.

Embodiment 3

[0031] Embodiment 3: Embodiment 3 is basically the same as Embodiment 1. The difference is that when the casing string is lowered into the wellbore, the top of the casing is used to connect the expansion tube, and the expansion tool is used to seal the expansion tube on the inner wall of the upper layer of casing. The specific difference is: when the connection length of the lower casing string reaches 1500 meters, the upper part is connected with a 1.3-meter 5" expansion pipe and expansion tool. The upper part of the 5" expansion pipe is connected with the drill pipe all the way to the wellhead. Then utilize the expansion tool to hang the expansion tube seat on the lower end inner wall of the 7 "technical sleeve. The process and method of expansion tube expansion sealing (seat hanging) have been used for decades, and those skilled in the art can complete it, so it will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com