Seal structure and seal method of engine camshaft cover

A technology of camshaft cover and sealing structure, which is applied to the sealing device of the engine, engine components, machines/engines, etc. It can solve the problems that affect the performance of the product, have many restrictions, and are difficult to meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

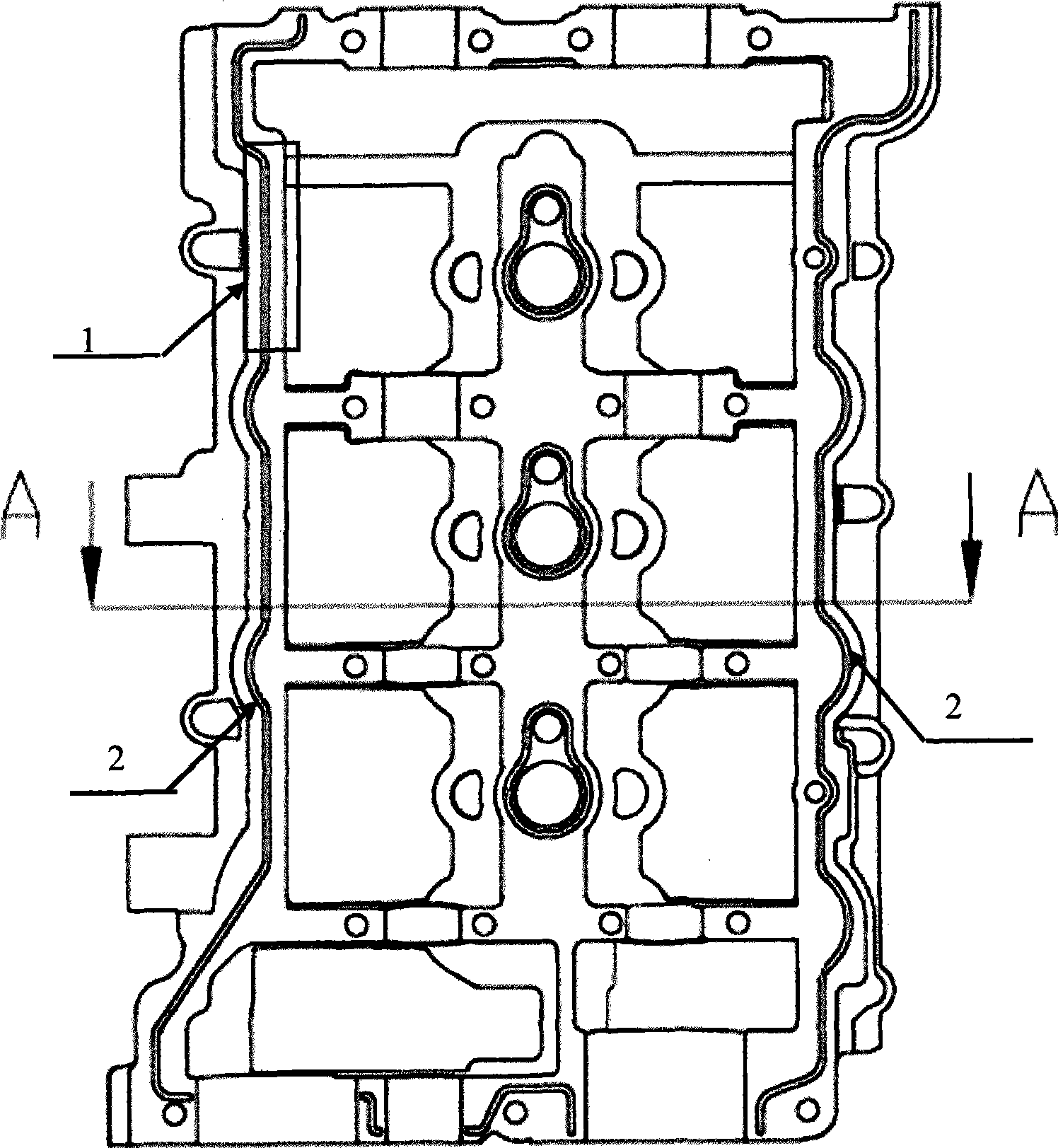

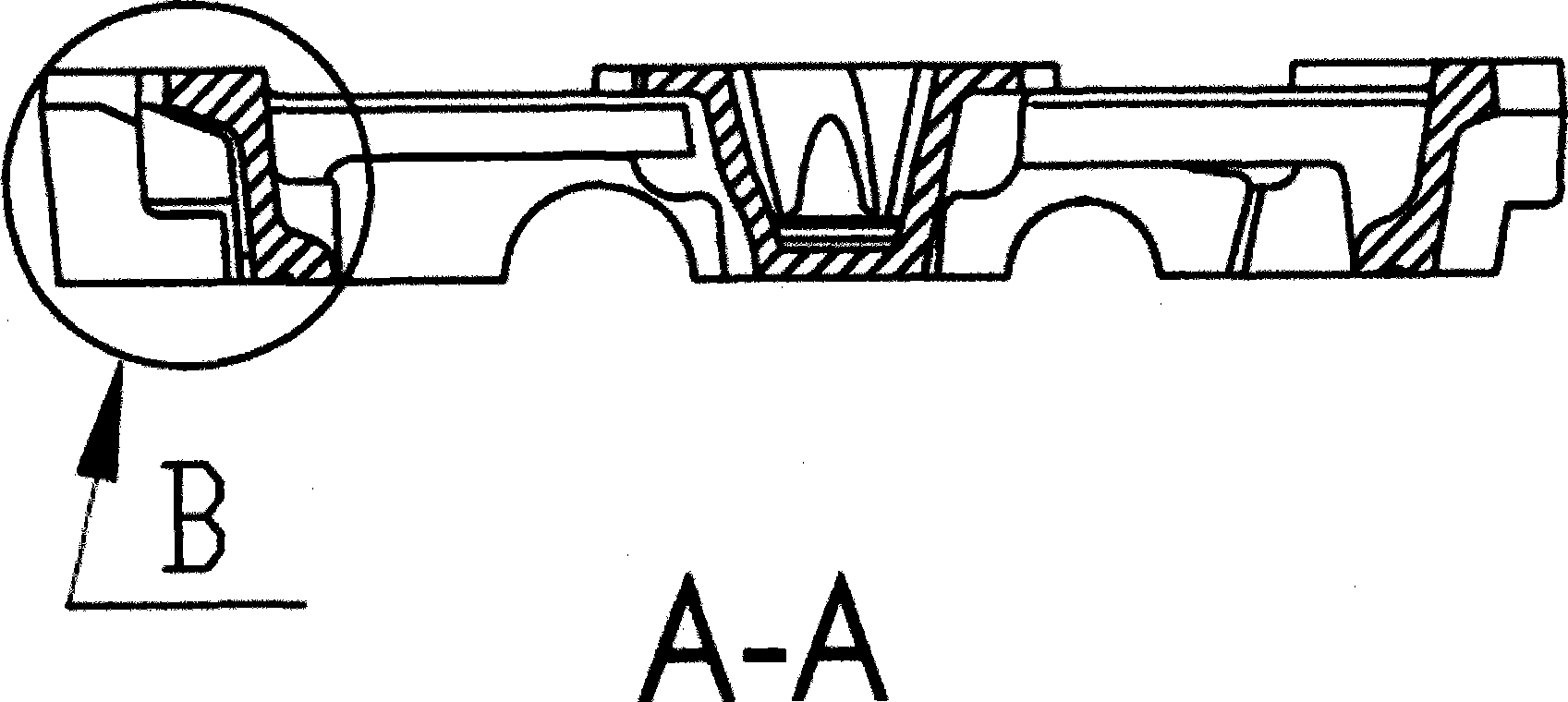

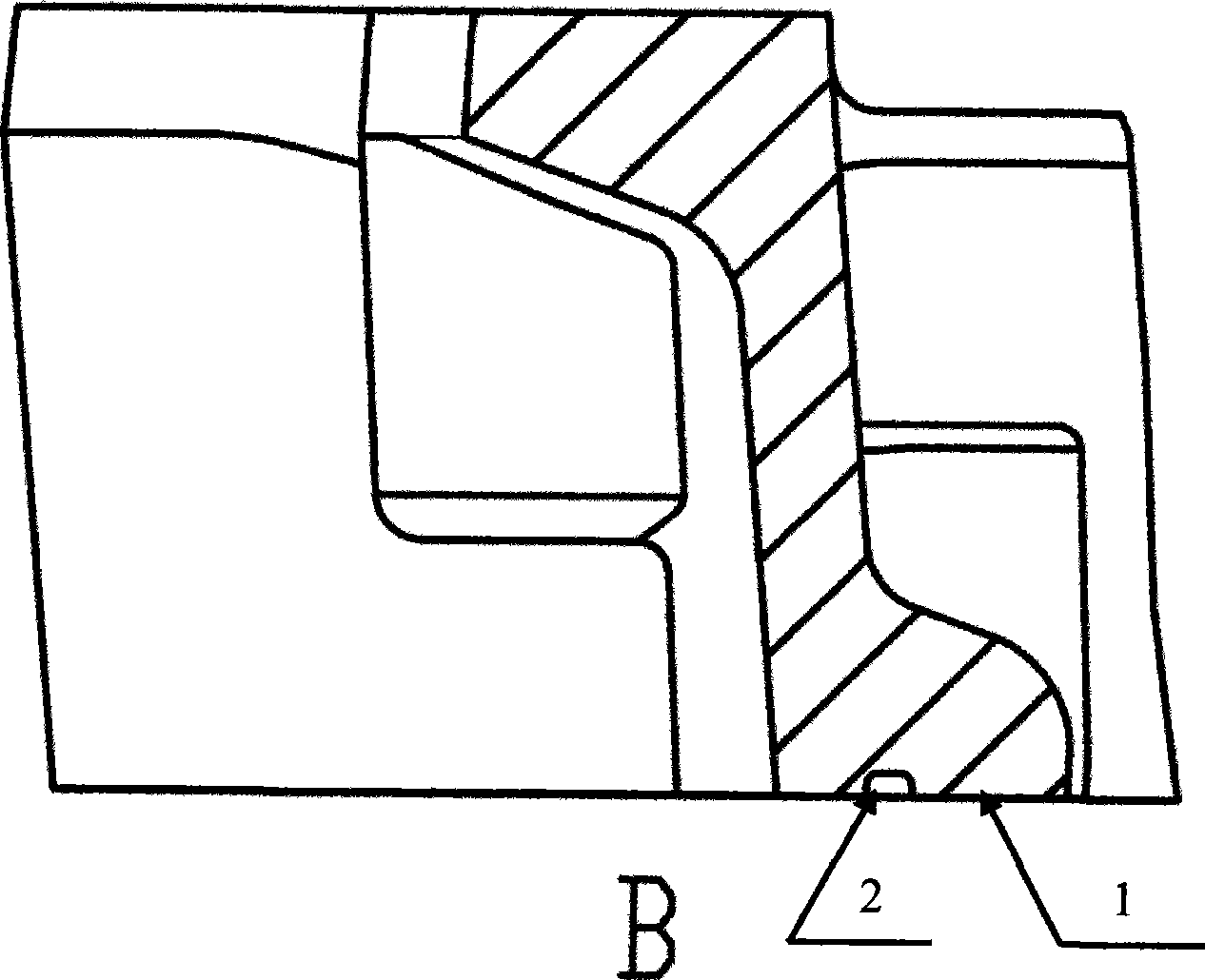

[0010] Such as figure 1 and figure 2 , the sealing surface 1 of the camshaft cover is engraved with a rubber storage tank 2, the rubber storage tank is engraved or reserved during casting, the rubber storage tank is filled with silica gel, and the camshaft cover is pressed tightly on the camshaft cover with bolts on the cylinder head.

[0011] Slots can play two roles. First, due to the relatively high viscosity of silica gel, if the silicone seal is used directly without grooves, after the bolts compress the camshaft cover, more silica gel will remain between the sealing surfaces and affect the camshaft hole. The roundness of the shaft hole, most of the silica gel remains in the groove after the groove, which can reduce the impact of the silica gel on the roundness of the shaft hole. Second, after the silica gel is cured, it is equivalent to adding an elastic gasket to the groove, which is beneficial to the sealing of the camshaft cover and the cylinder head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com