Composite structure of guardrail pipe

A technology of combined structure and guardrail tube, which is applied to the loss prevention measures of lighting devices, lighting devices, cooling/heating devices of lighting devices, etc. , good heat conduction, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

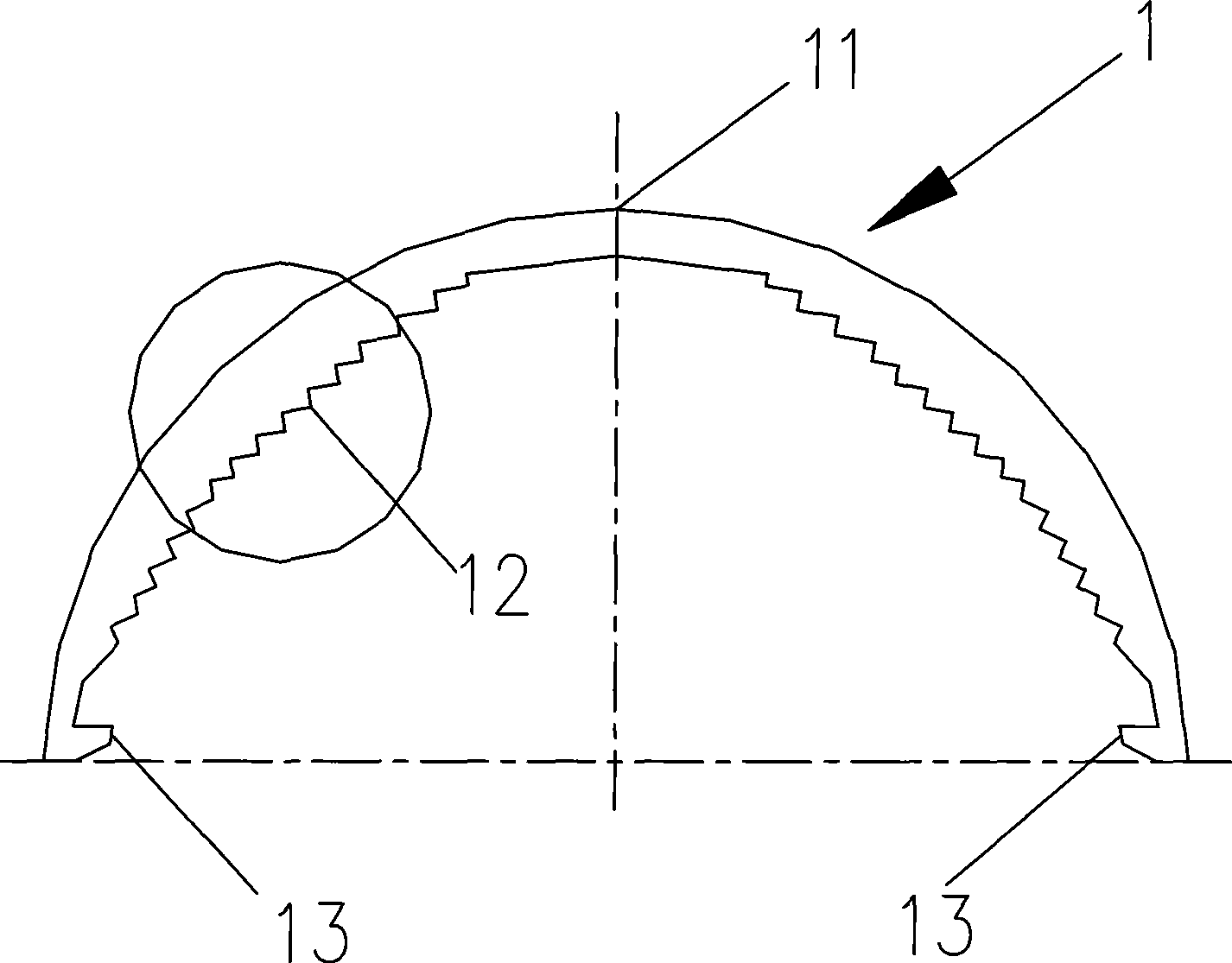

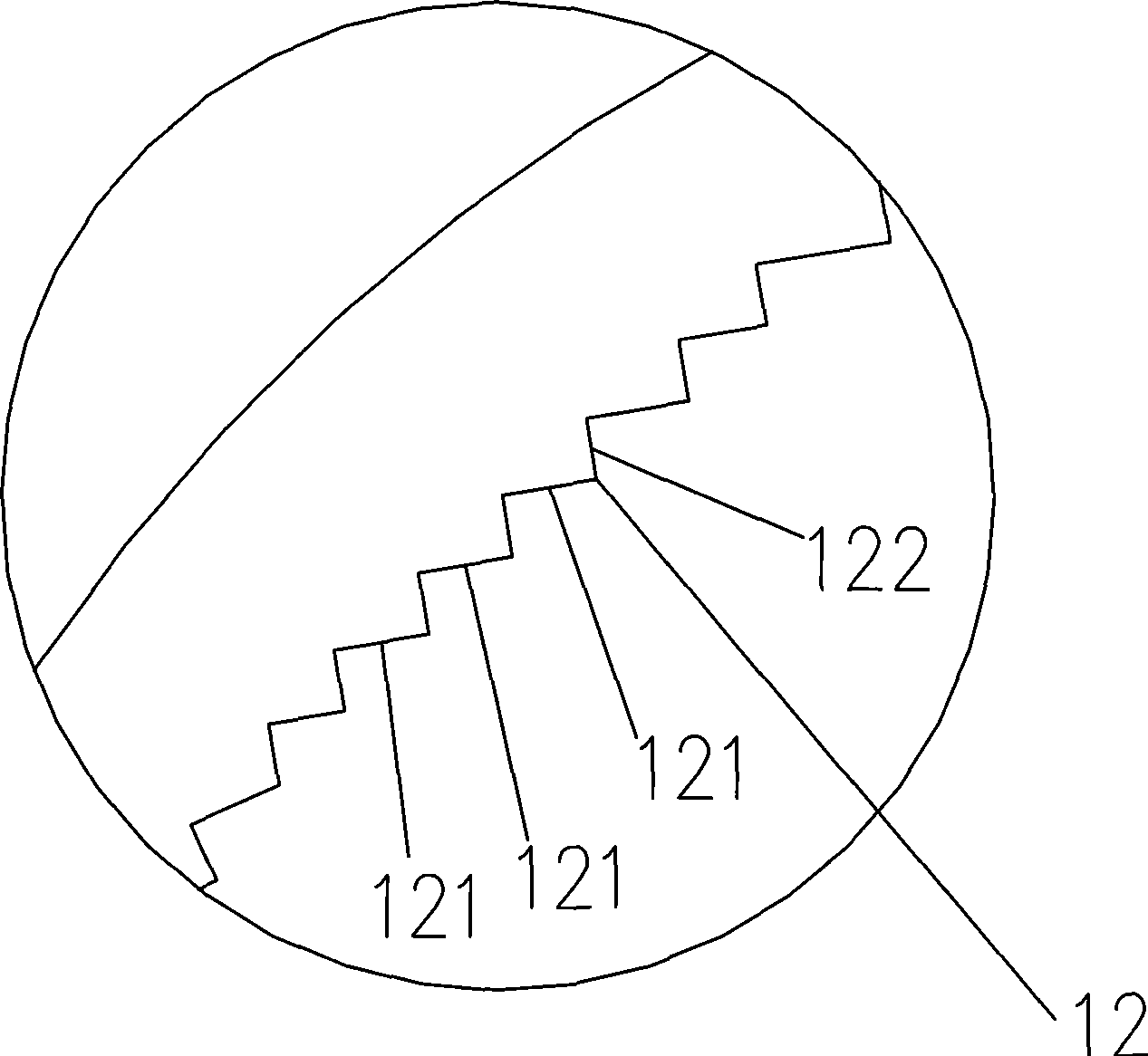

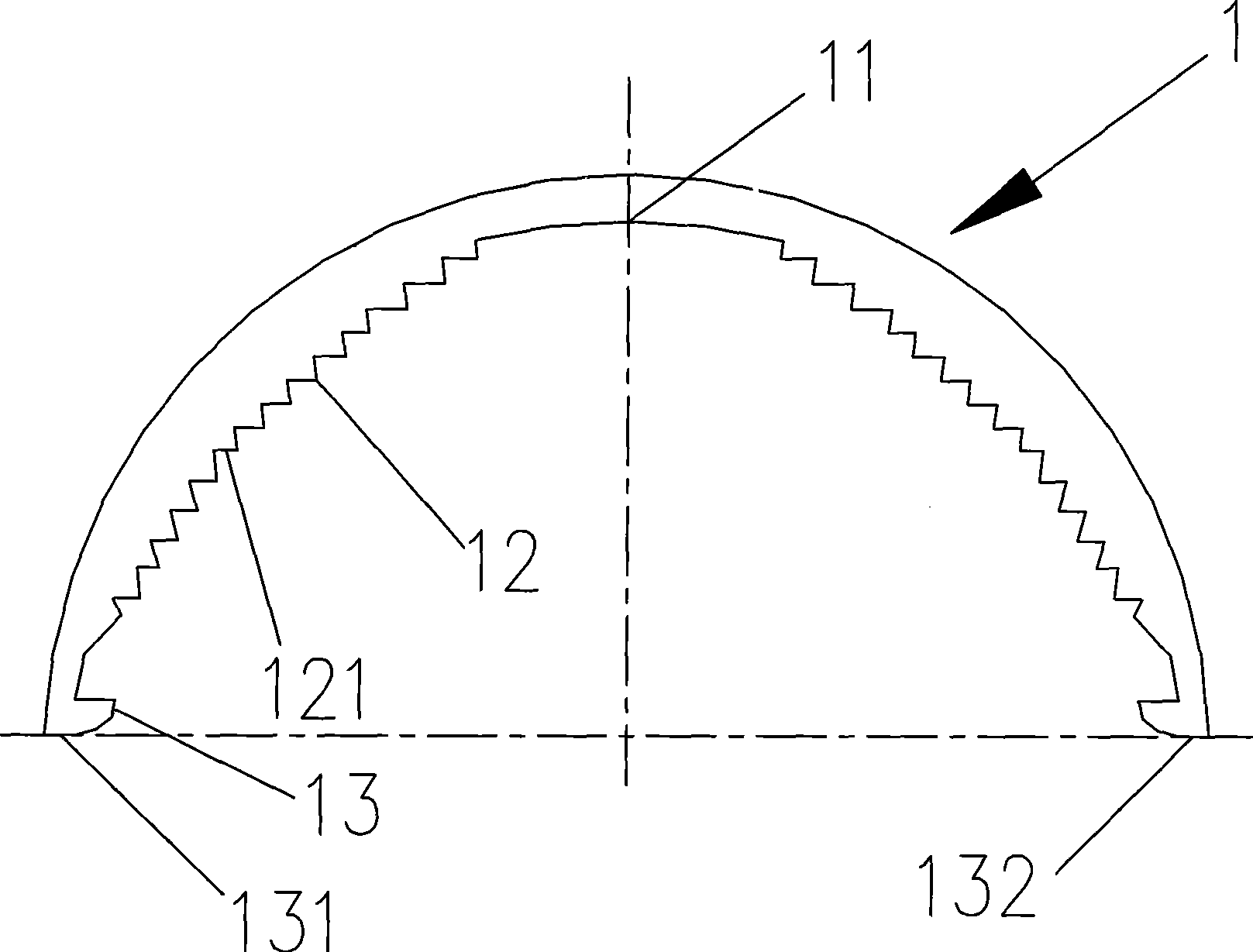

[0030] The combined guardrail tube structure of the present invention includes a light-transmitting polycarbonate surface shell 1 and an aluminum alloy bottom shell 2, both of which are semicircular in cross-section and can be interlocked to form a tubular shape. Such as figure 1 , figure 2 , image 3 As shown, the section of the elongated face shell 1 is semicircular, the central area 11 of the top of the face shell 1 is a smooth inner surface, the width of the central area is not less than 1 / 6 of the entire curved face shell, and the inner surfaces on both sides are provided with serrations 12 ,, Two symmetrical clamping strips 13 protruding inward are provided at both ends of the arc.

[0031] Each sawtooth 12 has two sides 121 , 122 , and the side 121 of the sawtooth on the same side of the face shell away from the top center 11 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com