A kind of high tensile strength waterproof and moisture-permeable composite fabric material and preparation process thereof

A high tensile strength, composite fabric technology, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc. High piercing strength, good moisture permeability, and the effect of solving moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

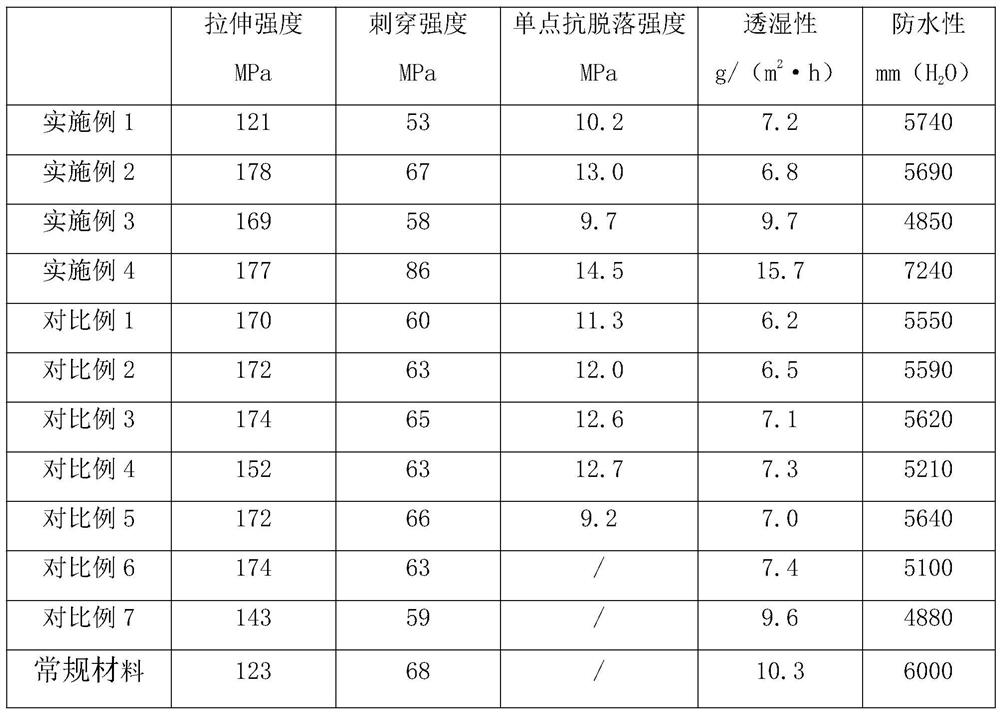

Examples

Embodiment 1

[0035] (1) Preparation of functional layer:

[0036] (a) mixing: take polyethylene with a molecular weight of 900,000 and a molecular weight distribution coefficient of 0.9 and white oil into a twin-screw extruder, melt, shear, and blend to obtain a mixture, and cast to form sheet A;

[0037] (b) Longitudinal stretching: After the sheet A is cooled, longitudinal stretching is performed to form a longitudinal hole structure, and the sheet B is obtained;

[0038] (c) One-time lateral stretching: take sheet B and carry out lateral stretching. During stretching, the stretching angle increases stepwise, and is divided into 3 stretching orientations. The angle ranges are: the first angle of 15°, The second angle is 45°, the third angle is 75°, the stretching temperature is 129°C, and sheet C is obtained;

[0039](d) extraction: the sheet C is immersed in the extraction solution, and the white oil therein is extracted to form a formed pore structure to obtain the sheet D;

[0040] ...

Embodiment 2

[0050] (1) Preparation of functional layer:

[0051] (a) mixing: take polyethylene with a molecular weight of 850,000 and a molecular weight distribution coefficient of 0.9 and white oil into a twin-screw extruder, melt, shear, and blend to obtain a mixture, and cast to form sheet A;

[0052] (b) Longitudinal stretching: After the sheet A is cooled, longitudinal stretching is performed to form a longitudinal hole structure, and the sheet B is obtained;

[0053] (c) One-time lateral stretching: take sheet B and carry out lateral stretching. During stretching, the stretching angle increases in a stepwise manner, and is divided into 3 stretching orientations. The angle ranges are: the first angle of 15°, The second angle is 45°, the third angle is 75°, the stretching temperature is 129°C, and sheet C is obtained;

[0054] (d) extraction: the sheet C is immersed in the extraction solution, and the white oil therein is extracted to form a formed pore structure to obtain the sheet ...

Embodiment 3

[0065] (1) Preparation of functional layer:

[0066] (a) mixing: take polyethylene with a molecular weight of 870,000 and a molecular weight distribution coefficient of 1.1 and white oil into a twin-screw extruder, melt, shear, and blend to obtain a mixture, and cast to form sheet A;

[0067] (b) Longitudinal stretching: After the sheet A is cooled, longitudinal stretching is performed to form a longitudinal hole structure, and the sheet B is obtained;

[0068] (c) One-time lateral stretching: take sheet B and carry out lateral stretching. During stretching, the stretching angle increases in a stepwise manner, and is divided into 3 stretching orientations. The angle ranges are: the first angle of 15°, The second angle is 45°, the third angle is 75°, the stretching temperature is 129°C, and sheet C is obtained;

[0069] (d) extraction: the sheet C is immersed in the extraction solution, and the white oil therein is extracted to form a formed pore structure to obtain the sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com