Heat acoustic refrigerating device based on oscillation flow hot pipe

A technology of oscillating flow heat pipe and thermoacoustic refrigeration, which is applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of low refrigeration efficiency and low heat exchange efficiency of heat exchangers, and achieves low cost and large promotion. The effect of value, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

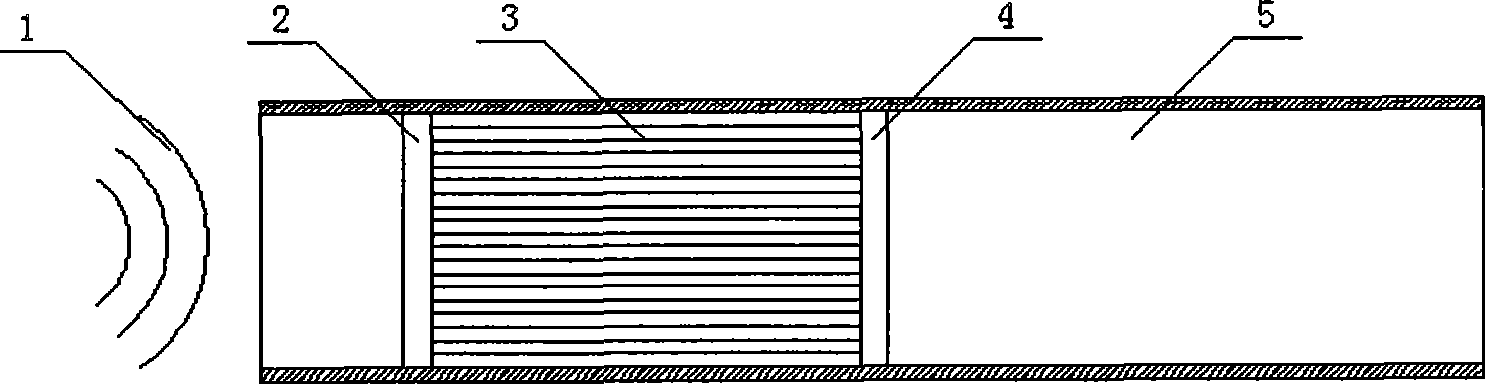

[0020] figure 1 Among them, the present invention includes a resonant cavity 5 filled with gas, a parallel plate stack 3 placed in the resonant cavity 5 , a hot end heat exchange device 2 , a cold end heat exchange device 4 and an acoustic wave generator 1 .

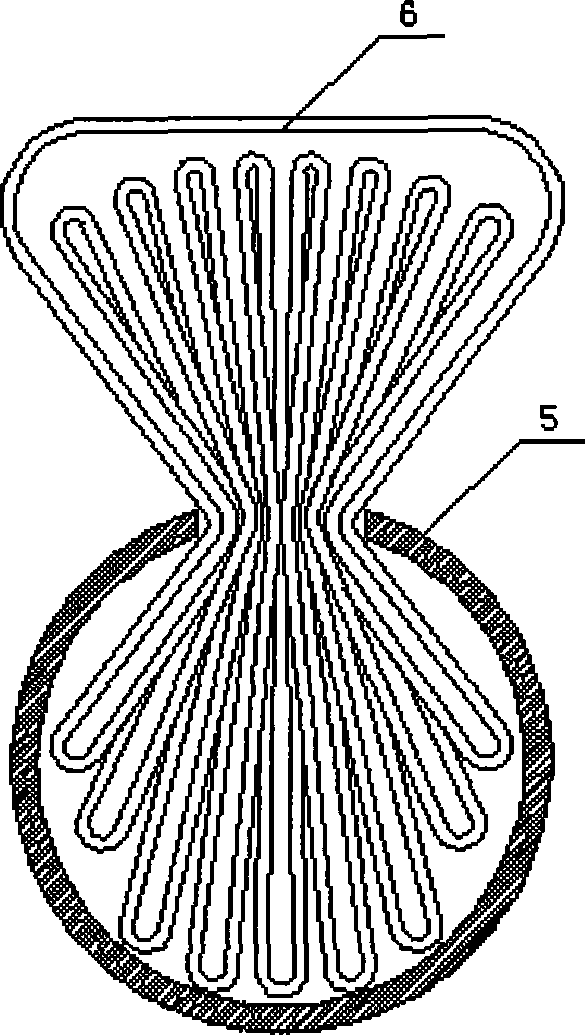

[0021] Both the hot end heat exchange device 2 and the cold end heat exchange device 4 are composed of a group of oscillating flow heat pipes 6, which are arranged orthogonally to the resonant cavity 5. The oscillating flow heat pipes 6 are serpentine loops formed by bending and welding capillary tubes. There is a closed interface on the thin tube, which is used for vacuuming and filling with working fluid.

[0022] Oscillating flow heat pipe: According to the specific heat exchange requirements, select a suitable metal thin tube (the metal tube is easy to process and suitable as a heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com