Low power consumption and high pressure resistant proportionality electromagnet

A proportional electromagnet, high-voltage technology, applied in the direction of electromagnet with armature, electromagnet, circuit, etc., can solve the problems of small output force/current, unfavorable stable operation, coil temperature rise, etc., to improve the output force/current ratio, improve the working stability, the effect of low temperature rise of the coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

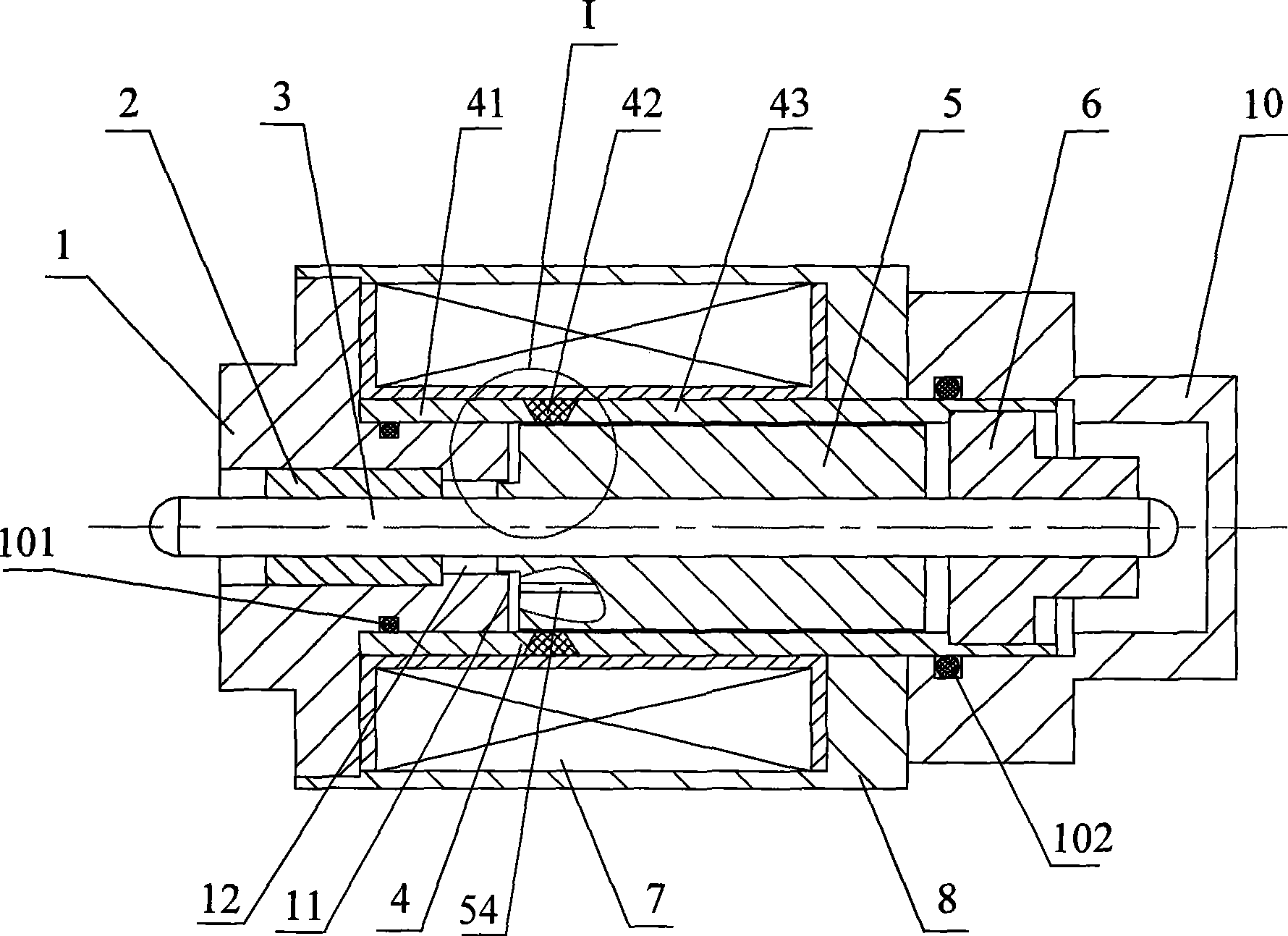

[0037] Figure 1 ~ Figure 2 In combination, a low-power consumption and high-voltage resistant proportional electromagnet is provided, which includes a housing 8 with a rectangular parallelepiped shape and a cylindrical inner hole and a cylindrical guide sleeve 4 with a cylindrical shape and a cylindrical inner hole (that is, the guide The cross-section at any place of the cover 4 is the circular ring of the same size); the guide cover 4 is located in the housing 8, and the control coil 7 is set between the guide cover 4 and the housing 8, and the control coil 7 can be selected as a concentric spiral Tubular control coil.

[0038] An armature 5 slidingly connected with the guide sleeve 4 is provided in the inner cavity of the guide sleeve 4 .

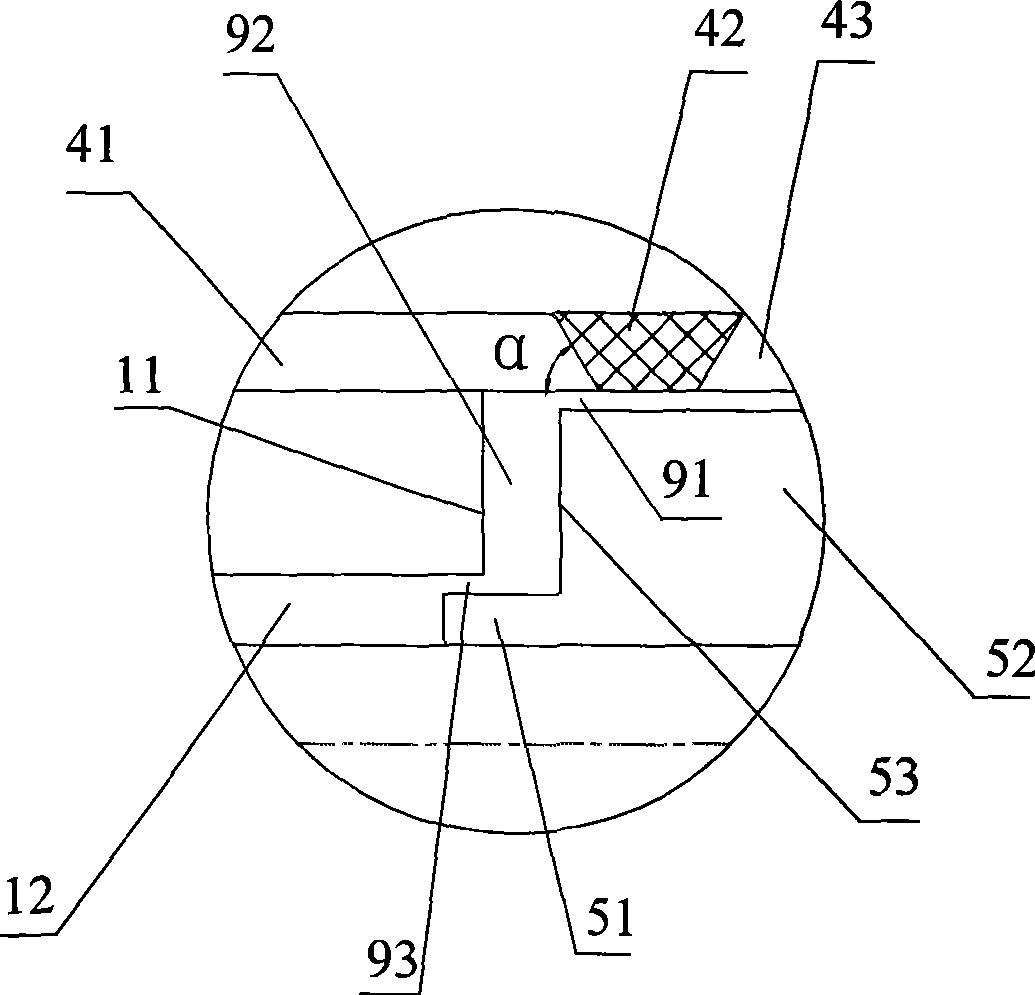

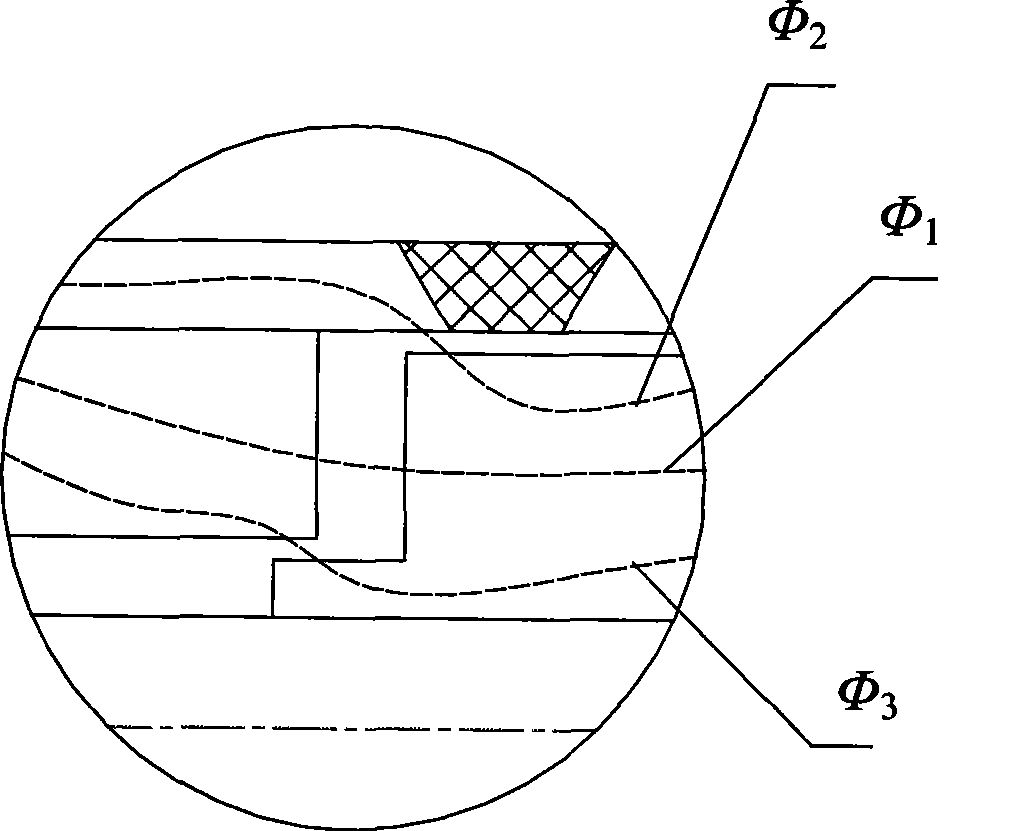

[0039] The guide sleeve 4 is composed of the front section 41, the middle section 42 and the back section 43 which are connected in sequence. In order to obtain good output characteristics, the taper angle α should be controlled at 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com