Digitized discrete cell driving combing machine

An independent unit and independent drive technology, applied in the field of combing machines, can solve the problems of complex transmission mechanism, unfavorable high-speed impact and vibration, and difficulty in adjusting combing process parameters, so as to improve the spinning performance, improve the quality, facilitate the design and The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

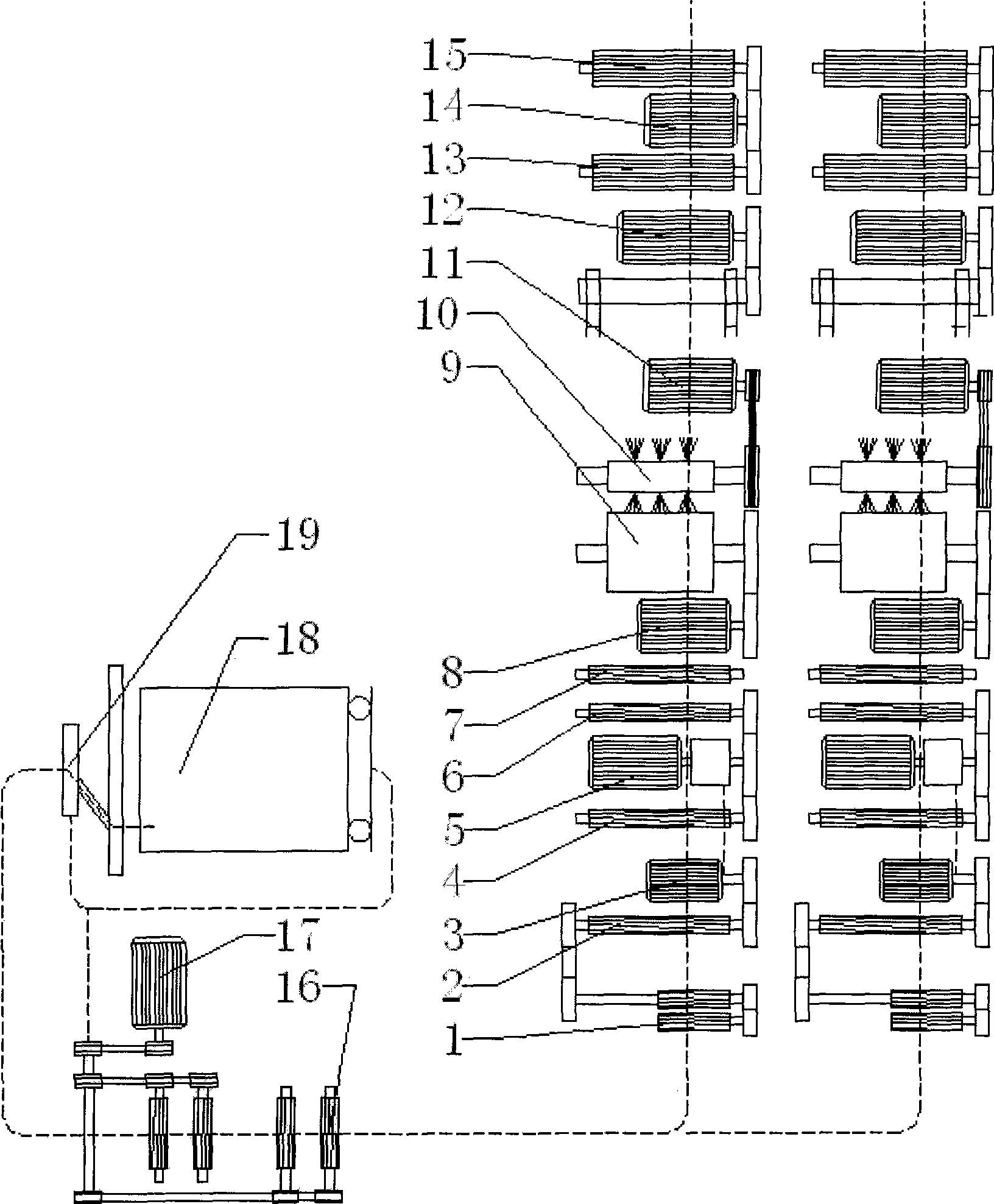

Embodiment 1

[0018] A digital independent unit-driven combing machine, the brush 10 is equipped with an independent brush motor 11, and the car body is a six-eye combing head, composed of 3 double-eye digital independent units, and the front and rear supporting rollers 13, 15 are shared The bearing roller motor 14, the cylinder shaft 9 are equipped with an independent cylinder shaft motor 8, the nipper shaft is equipped with an independent nipper shaft servo motor 12 and a drive controller, the front and rear separation rollers 4 and 6 are shared and separated The roller servo motor 5 is also equipped with a drive controller. The lead roller 2 is driven by the lead roller motor 3, and the lead roller 2 is connected to the pressure roller 1. The draft roller 16 and the coiler 18 share the drafting and coiler motor 17. A signal generator is provided on the cylinder shaft 9 of the steel tube. The rolling roller motor 14, the lead-out roller motor 3, the drafting and coiler motor 17 are all servo ...

Embodiment 2

[0021] A digital independent unit-driven combing machine, the brush 10 is equipped with an independent brush motor 11, the car body is an eight-eye combing head, composed of two four-eye digital independent units, and the front and rear supporting rollers 13, 15 are shared The bearing roller motor 14, the cylinder shaft 9 are equipped with an independent cylinder shaft motor 8, the nipper shaft is equipped with an independent nipper shaft servo motor 12 and a drive controller, the front and rear separation rollers 4 and 6 are shared and separated The roller servo motor 5 is also equipped with a drive controller. The lead roller 2 is driven by the lead roller motor 3, and the lead roller 2 is connected to the pressure roller 1. The draft roller 16 and the coiler 18 share the drafting and coiler motor 17. A signal generator is arranged on the cylinder shaft 9 of the steel, and both the signal generator and the drive controller are connected with the combing machine control device th...

Embodiment 3

[0023] A digital independent unit-driven combing machine, the brush 10 is equipped with an independent brush motor 11, the car body is an eight-eye combing head, composed of 8 single-eye digital independent units, and the front and rear supporting rollers 13, 15 are shared The bearing roller motor 14, the cylinder shaft 9 are equipped with an independent cylinder shaft motor 8, the nipper shaft is equipped with an independent nipper shaft servo motor 12 and a drive controller, the front and rear separation rollers 4 and 6 are shared and separated The roller servo motor 5 is also equipped with a drive controller. The lead roller 2 is driven by the lead roller motor 3, and the lead roller 2 is connected to the pressure roller 1. The draft roller 16 and the coiler 18 share the drafting and coiler motor 17. A signal generator is arranged on the cylinder shaft 9 of the steel, and both the signal generator and the drive controller are connected with the combing machine control device th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com