Electromagnetic force driving mechanism of an SF6 high voltage circuit breaker

A high-voltage circuit breaker and driving mechanism technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, electromagnets, etc., can solve the problems of uncontrollable movement process, high manufacturing process requirements, complex transmission mechanism, etc., and achieve low inertia. , Small quality, the effect of preventing loss of magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention uses 126kV SF 6 Take the circuit breaker as an example, the arc extinguishing chamber requires the electromagnetic drive mechanism to provide the opening electromagnetic thrust of 21000N, and the opening speed is 4.2-4.8m / s; when closing, its electromagnetic thrust is 15000N, and the closing speed is 1.4-1.7m / s.

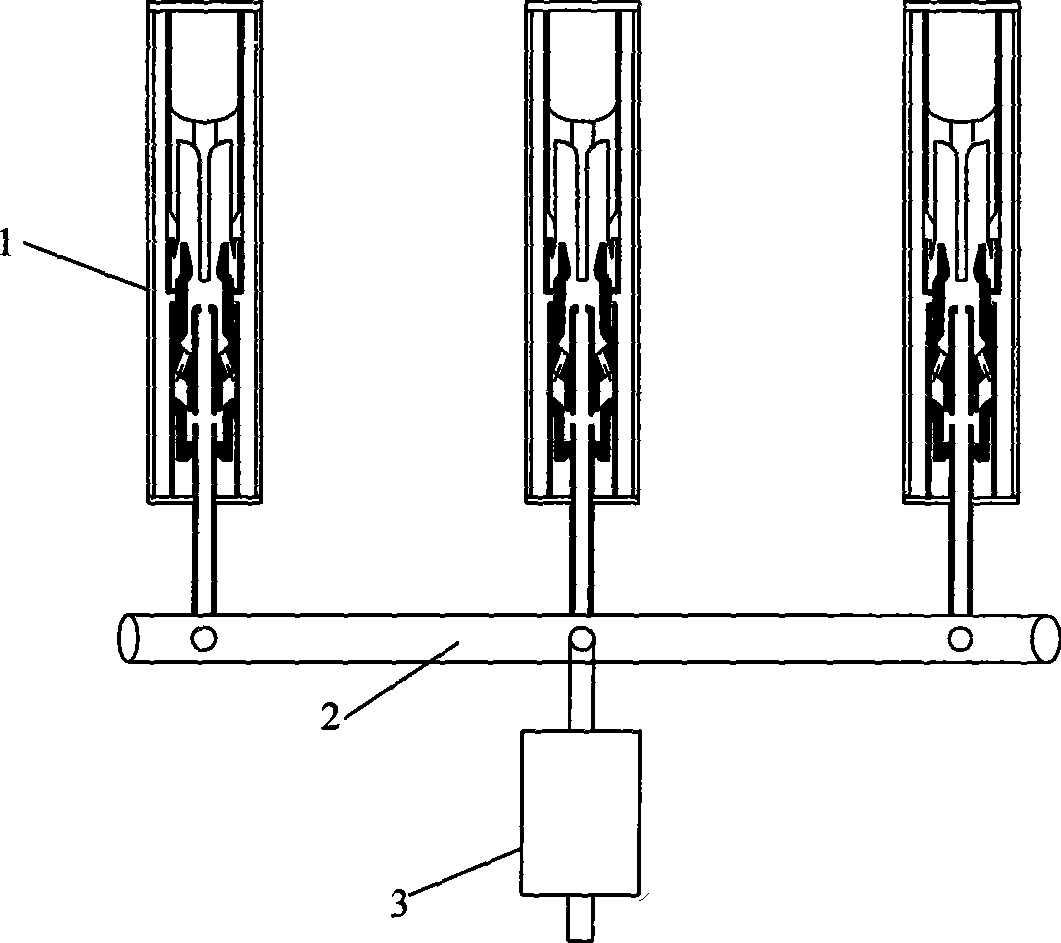

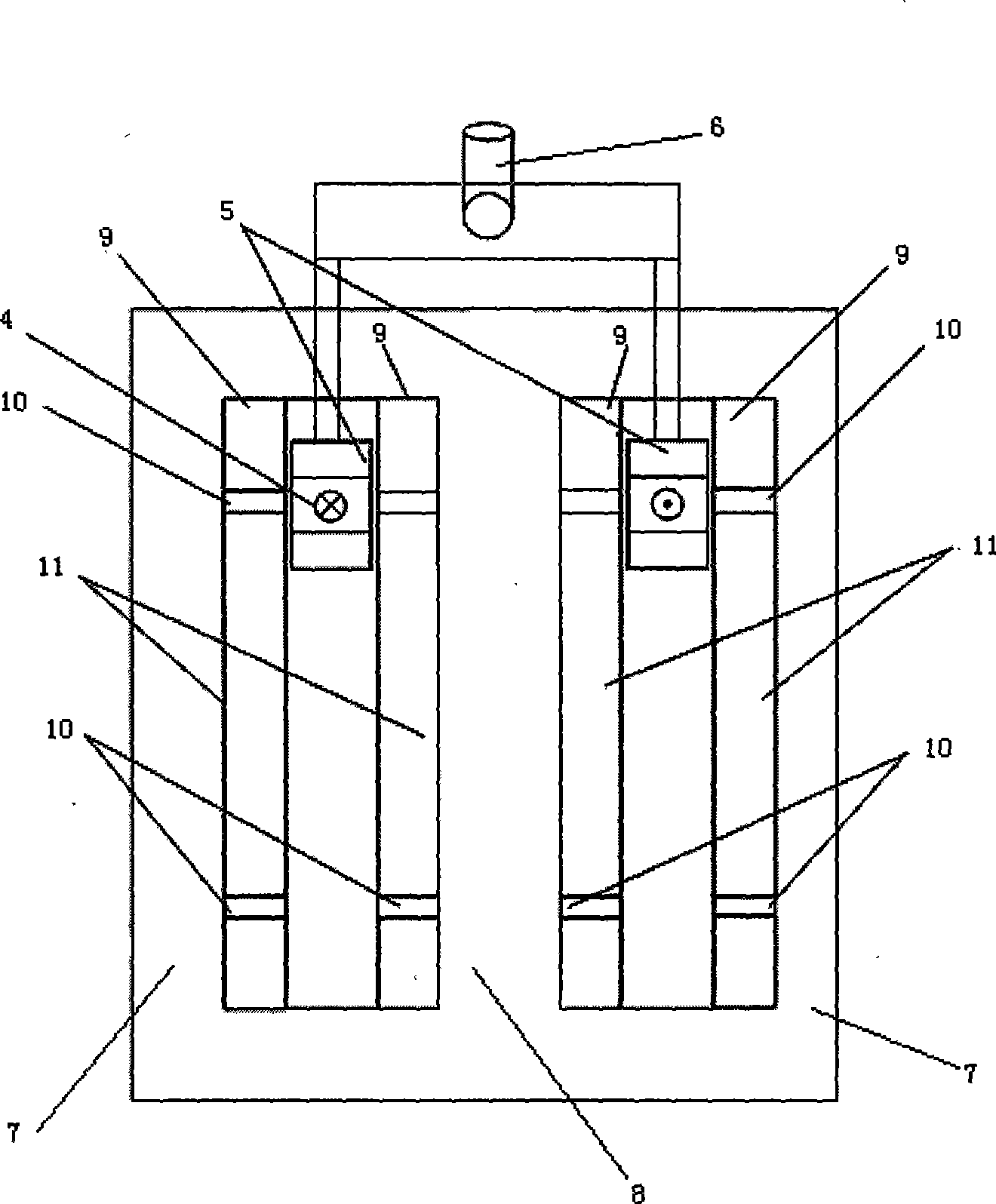

[0015] The device as figure 1 Shown includes SF 6 High-voltage circuit breaker, connecting rod 2 and electromagnetic force driving mechanism 3, transmission rod 6 and SF of electromagnetic force driving mechanism 3 6 The moving contact 1 of the high-voltage circuit breaker is connected by the connecting rod 2, and the secondary iron core 5 in the electromagnetic force drive mechanism 3 is subjected to the action of the electromagnetic force in the magnetic field to drive the SF 6 The moving contact 1 of the high-voltage circuit breaker moves on and off, and the auxiliary permanent magnet 9 in the electromagnetic force driving mechanis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com