Light emitting diode and preparation method thereof

A technology of light-emitting diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problem of separation of circuit boards and heat-conducting seats, and achieve effective fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

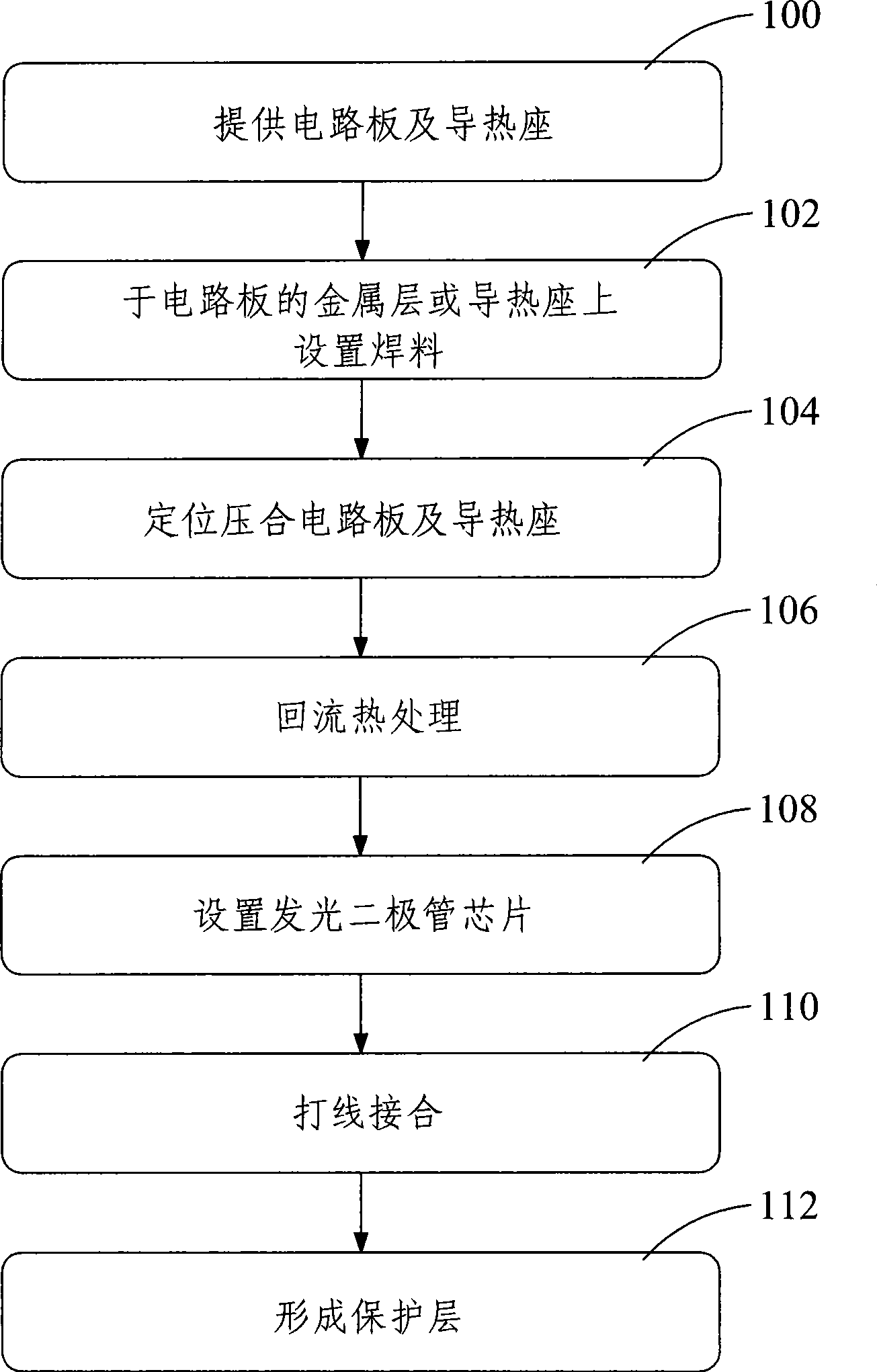

[0026] refer to figure 1 , according to the flowchart of the light-emitting diode manufacturing method of the present invention, the manufacturing method includes the following steps:

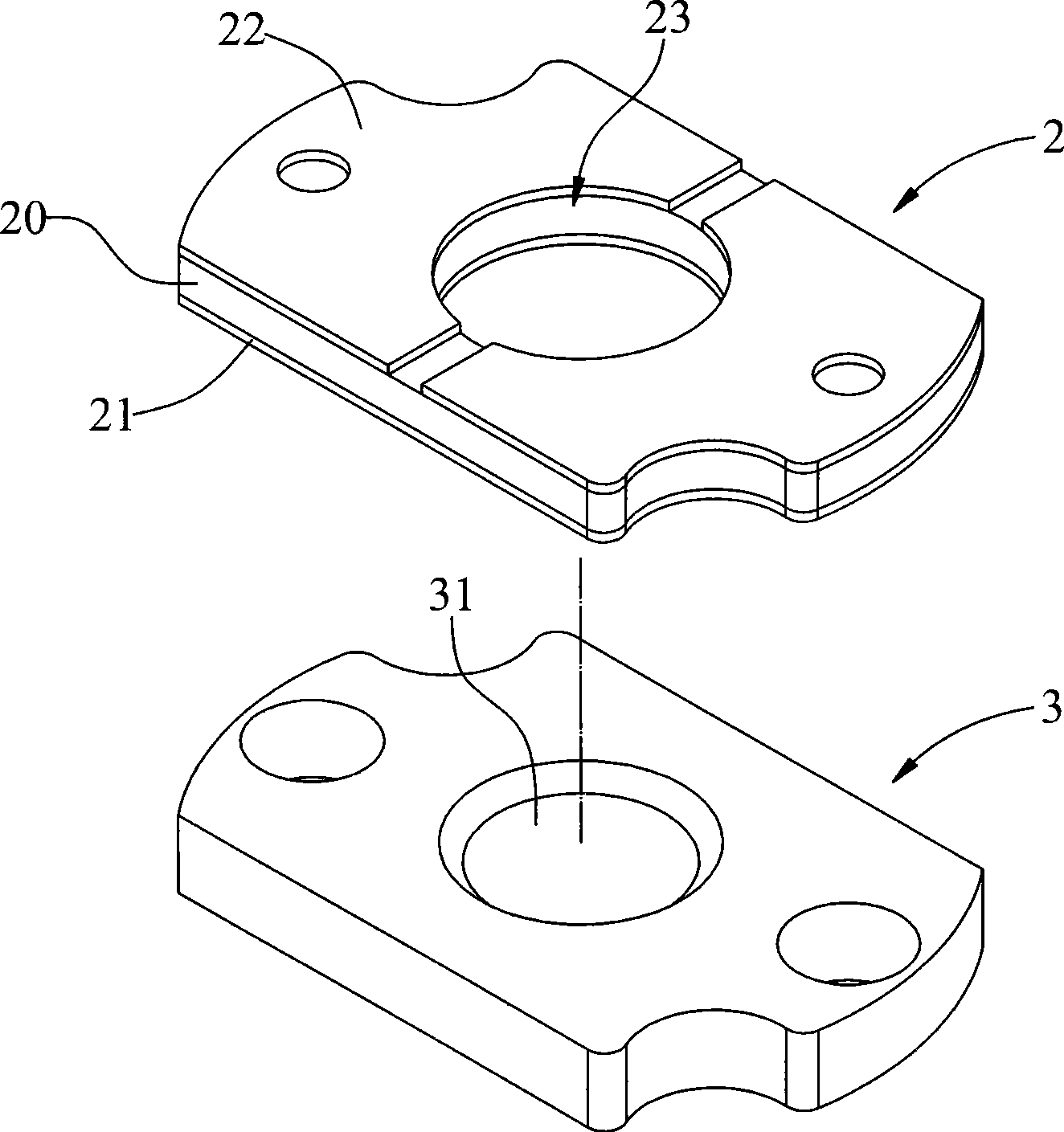

[0027] First, as in step 100, refer to figure 2 , providing circuit board 2 and heat conduction seat 3 .

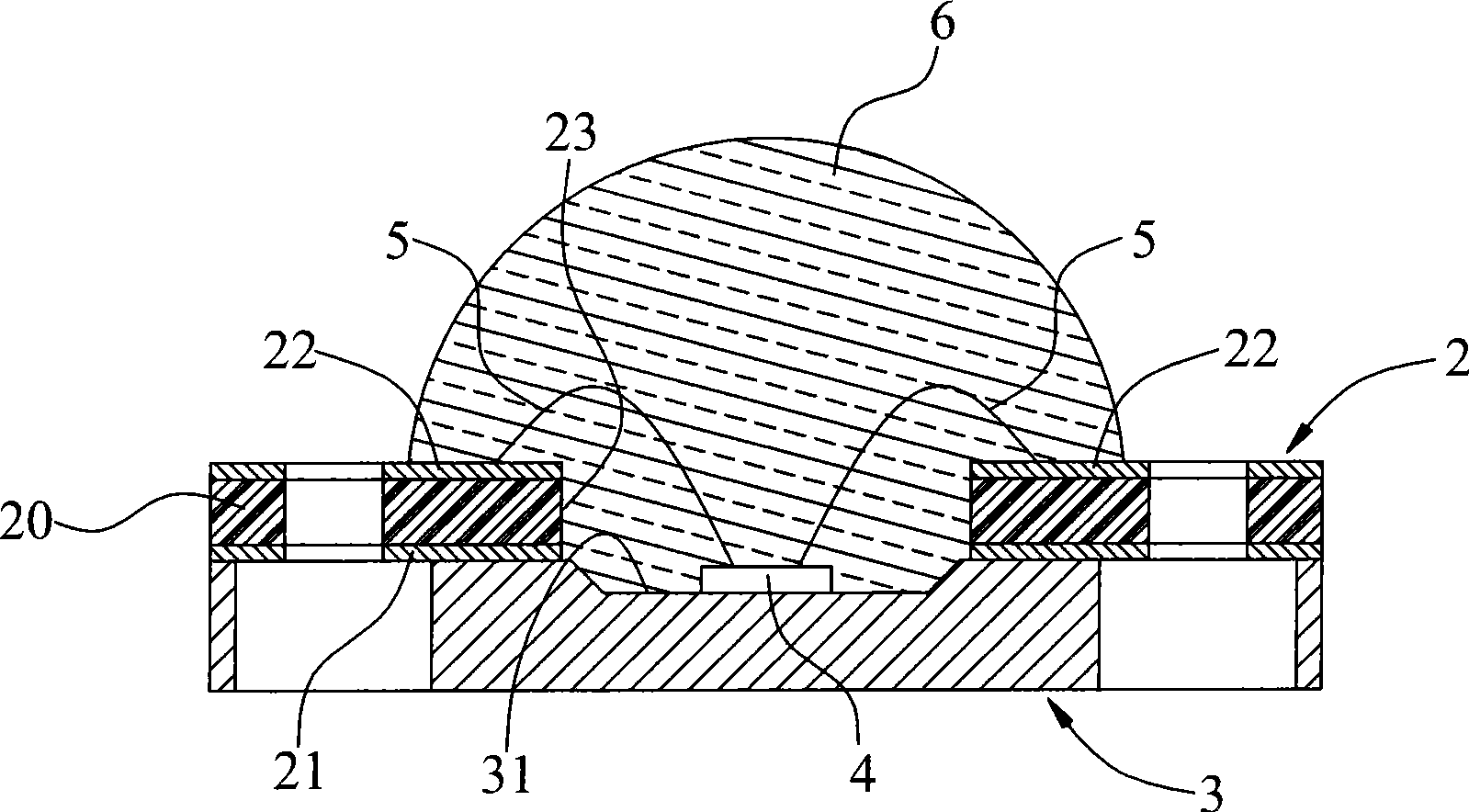

[0028] The circuit board 2 includes an insulating plate 20, a metal layer 21 disposed on the lower surface of the insulating plate 20, two electrode layers 22 spaced apart on the upper surface of the insulating plate 20, and the following metal layers penetrating through the upper and lower surfaces of the circuit board 2. The through hole 23 of the LED chip is exposed. The circuit board 2 can be a single-layer printed circuit board with double-sided copper foil, and these electrode layers 22 are made by performing processes such as photoresisting, exposure, development, etching, and photoresist removal on one of the copper foils. , and the printed circuit board is cut and drilled in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com