Roller earthing structure of dryer

A grounding structure, a technology for clothes dryers, applied in the field of clothes dryers, can solve problems such as poor electrical connection stability, drum wear, etc., and achieve the effects of convenient installation, simple structure, and good mechanical and electrical connection stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

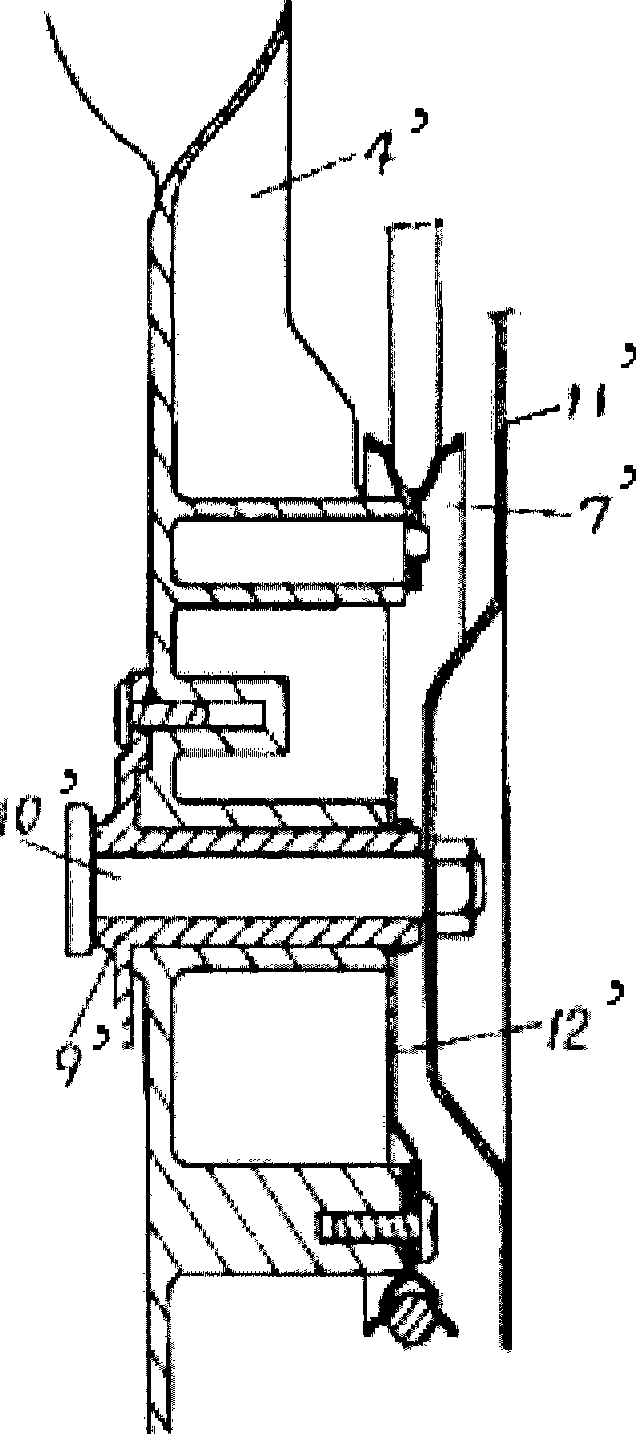

[0033] like Figure 4 to Figure 7 As shown, the drum shaft 3 at the rear end of the dryer drum according to the present invention corresponds to the housing rear plate 4, and between the drum shaft 3 and the housing rear plate 4 is a conductive rolling ball 8 and a connecting piece 11, the connecting piece 11 is fixed on the rear plate 4 of the shell, and the position corresponding to the rolling ball 8 is provided with an elastic sheet 12. The elastic sheet 12 is close to the rolling ball 8, and its elastic force makes the rolling ball 8 close to the end surface of the roller shaft 3. The connecting piece 11 is fixed on the outside of the back plate 4 of the housing by fixing screws 13, the rear plate 4 is a hollow hole 14 corresponding to the rolling ball, the hollow hole 14 of the back plate is slightly larger than the diameter of the rolling ball 8, and the elastic piece 12 is " U"-shaped stamping structure, which blocks the rolling ball 8 in the hollow hole of the back pl...

Embodiment 2

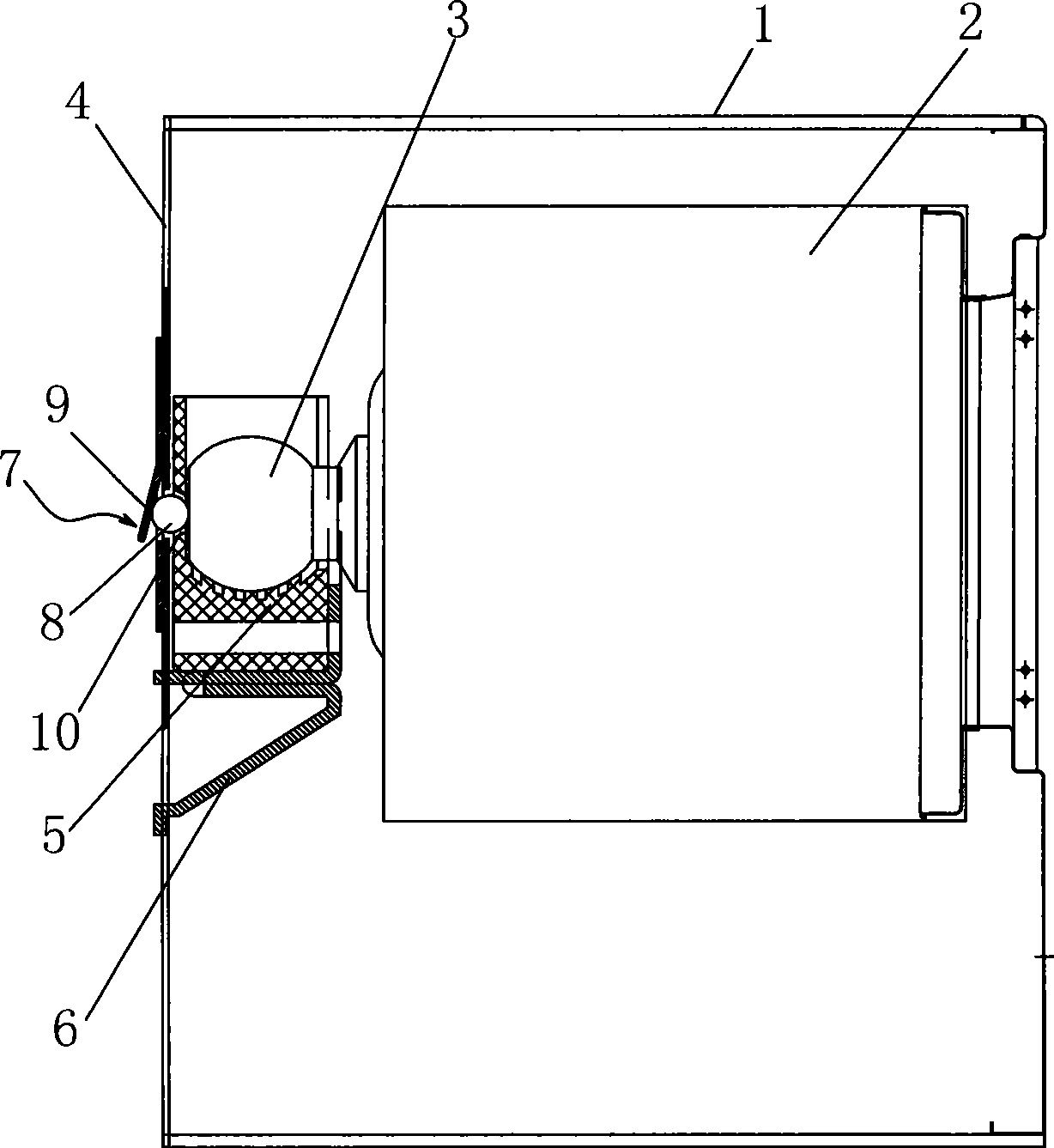

[0035] like Figure 8 As shown, the drum shaft 3 at the rear end of the dryer drum according to the present invention corresponds to the housing rear plate 4, and between the drum shaft 3 and the housing rear plate 4 is a conductive rolling ball 8 and a spring 15, and one end of the spring 15 is It is close to the rolling ball 8, and the other end is close to the shell rear plate 4. The rolling ball 8 and the spring 15 are independent individuals. In order to fix the spring 15 and the rolling ball 8 without displacement, the rolling ball 8 and the spring 15 can also be It is fixed as a whole, and the other end of the spring 15 is fixed with the rear plate 4 .

Embodiment 3

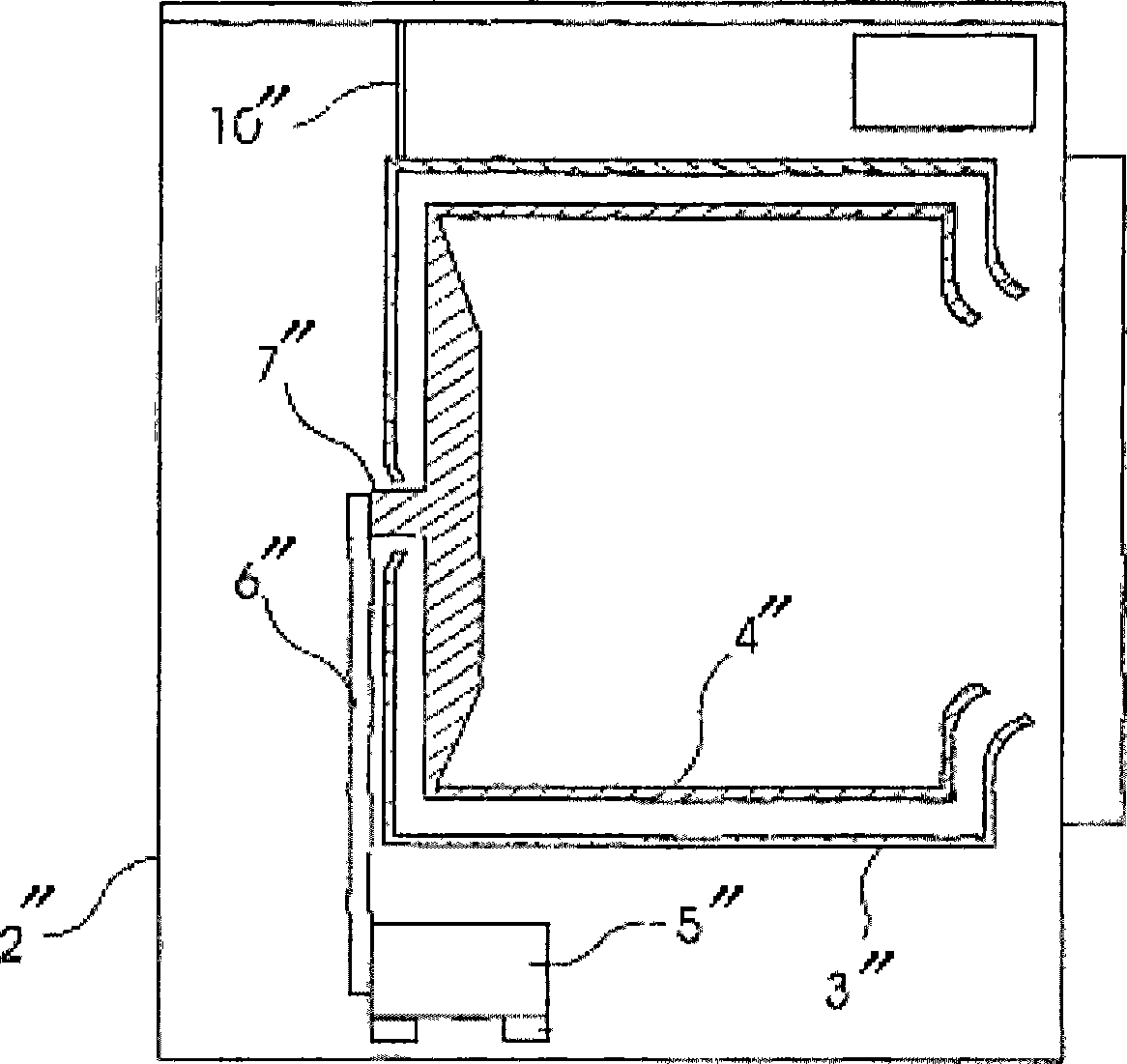

[0037] like Figure 9 As shown, the drum shaft 3 at the rear end of the dryer drum according to the present invention corresponds to the housing rear plate 4, and between the drum shaft 3 and the housing rear plate 4 is a conductive rolling ball 8 and an elastic sheet 16, the elastic sheet 16 is integrated with the shell back plate 4, correspondingly close to the rolling ball 8, and its elastic force makes the rolling ball 8 close to the end surface of the cylinder shaft 3.

[0038] The end surface of the roller shaft in the present invention is a plane, so that the contact between the rolling ball and the roller shaft is at one point, thereby reducing the rotating friction of the roller and reducing the noise.

[0039] In the present invention, a rolling ball and an elastic member are installed between the shell rear plate and the roller shaft, and the elastic member presses the rolling ball tightly on the rear end surface of the installed roller rotating shaft, so as to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com