Valve mechanism and variable damping damper using the same

A shock absorber and valve technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of complex structure, difficult processing and manufacturing, etc., and achieve the effect of changing the shock absorber effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to enable your review committee to have a further understanding and understanding of the characteristics, purpose and functions of the present invention, the relevant detailed structure and design concept of the device of the present invention will be explained below, so that the review committee can understand the present invention The characteristics are described in detail as follows:

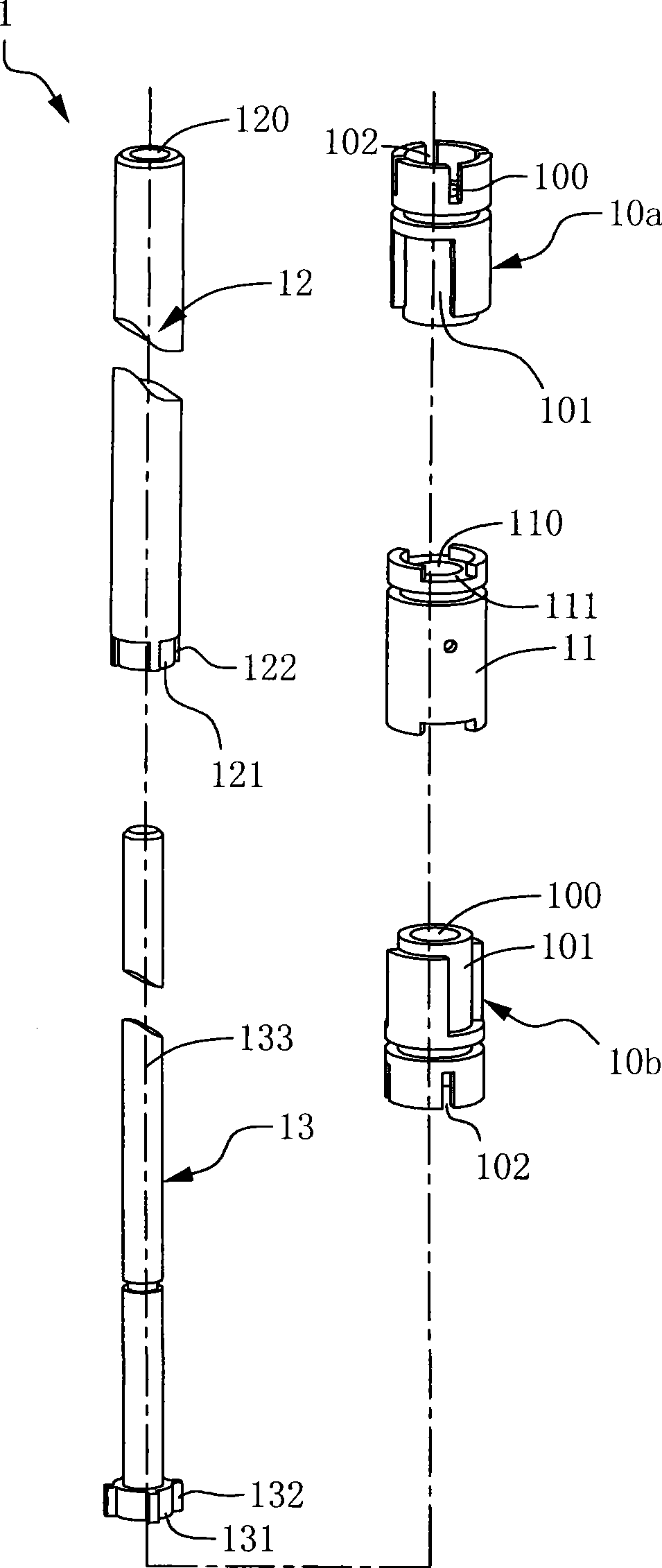

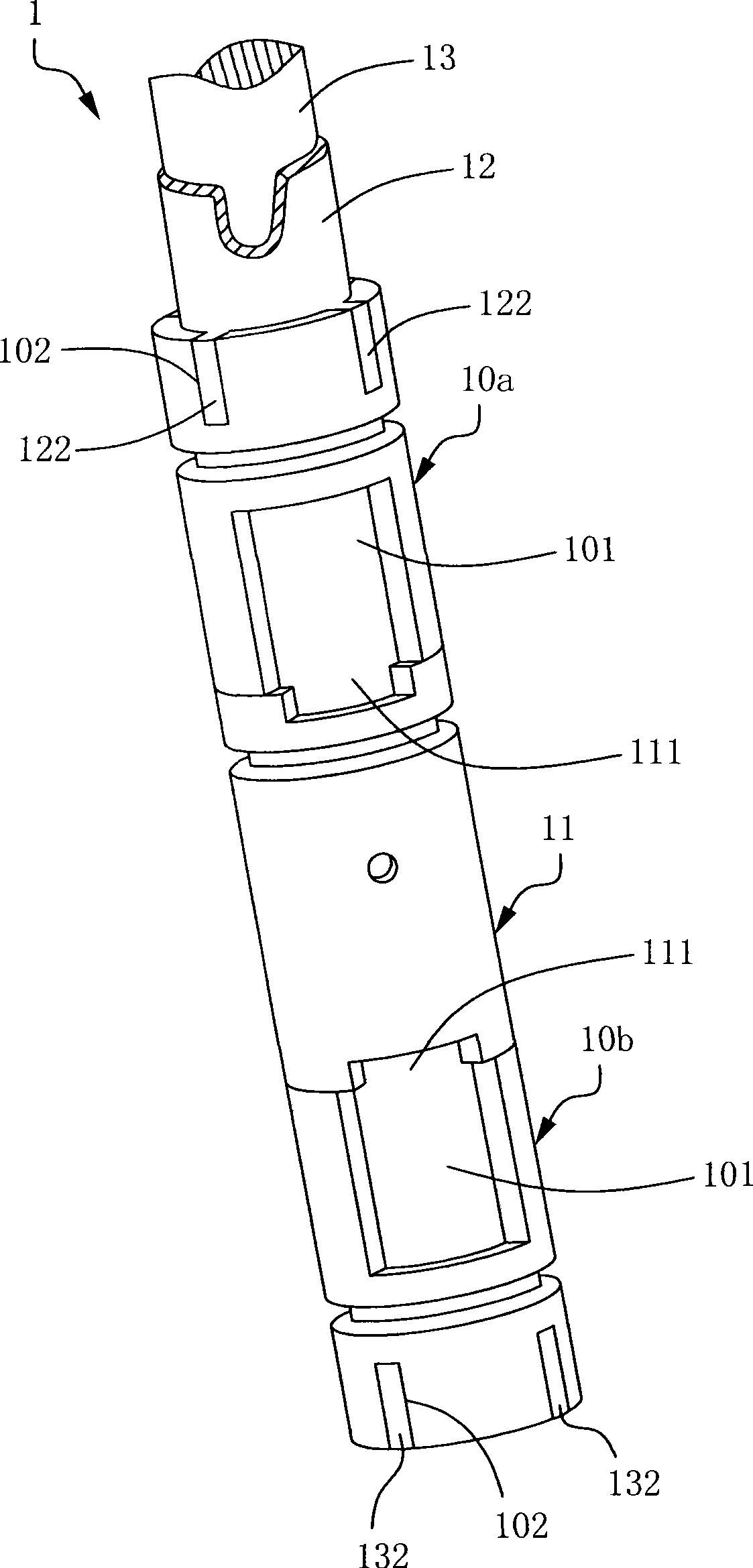

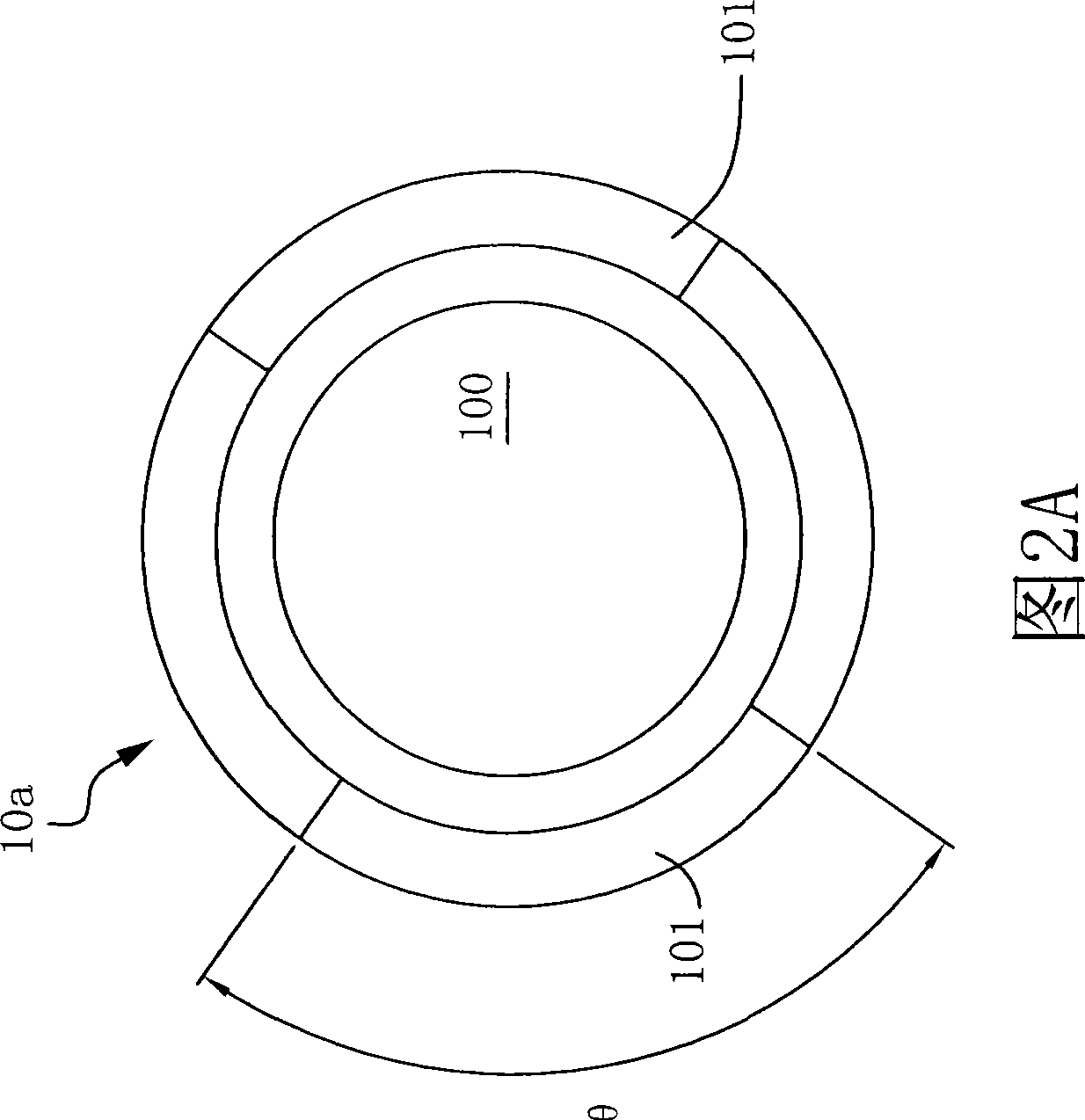

[0075] see Figure 1A as well as Figure 1B As shown, this figure is a three-dimensional exploded and assembled schematic diagram of a preferred embodiment of the valve mechanism of the present invention. The valve mechanism 1 has a pair of rotary valves 10 a and 10 b , a control valve 11 and a pair of rotary rods 12 and 13 . Each of the rotary valves 10 a and 10 b has a through hole 100 inside, and at least one flow path is disposed on the outer wall thereof. In this embodiment, the flow path is formed by a set of grooves 101 . As shown in FIG. 2A , which is a schematic bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com