Melt fabrication of fiber-filled fluoropolymer

A melt processing, polymer technology, used in the field of fluoropolymers, which can solve the problems of slow extrusion rate, long cycle, incomplete filling of molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

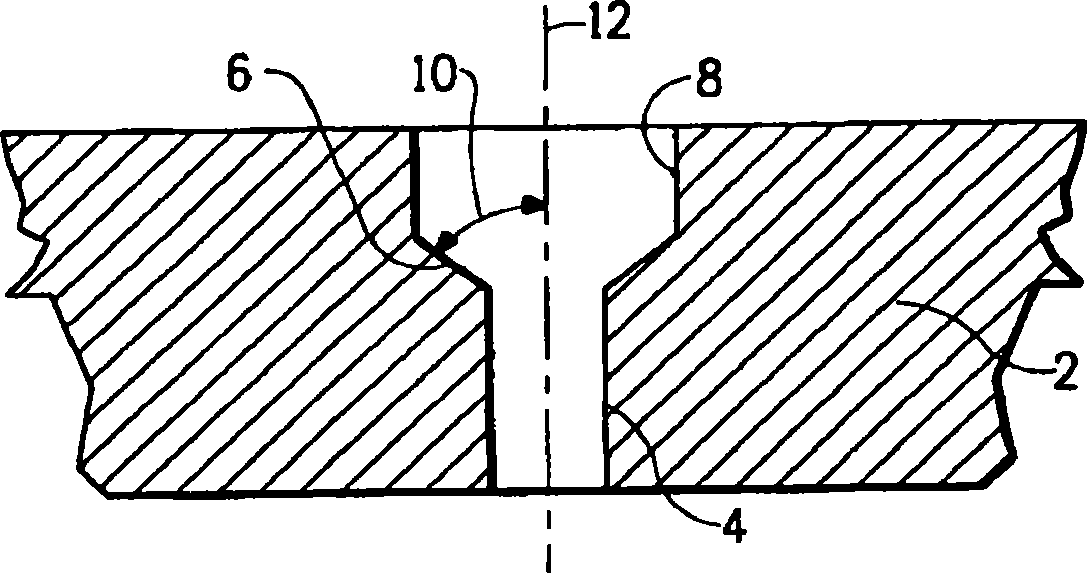

[0035] The fluoropolymers used in these examples were as 200 ETFE Fluoropolymer available as ETFE from E.I. du Pont de Nemours and Company, said polymer having a melt flow rate of 7 g / 10 min measured at 297°C, and having a diameter of about 125 mils (3185 microns) and 175 mils An ear (4460 micron) length extruded melt-formed pellet form. The fibers used in the examples were glass fibres, but similar results could be obtained with any of the other fibers mentioned above. The glass fibers used were purchased from St. Gobain / Vetrotex as grade 910 chopped E-glass strands with a fiber length of approximately 188 mils (4.5 mm) and a fiber diameter of 10 microns. A dry blend composition was prepared containing 30% by weight glass fibers and 70% by weight ETFE pellets. This composition was added to a single screw operating at 10 rpm and heated to a melting temperature of 585°F (307°C). mixer, which passes the molten composition through Figure 4 The die extrusion shown has a 64...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com