A preparation method of high temperature resistant fluoropolymer microporous material

A microporous material, high temperature resistant technology, applied in the field of polymer microporous material preparation, can solve environmental hidden dangers, limit the large-scale application of fluoropolymers, etc., to increase porosity, improve dissolution and diffusion capacity, reduce The effect of melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

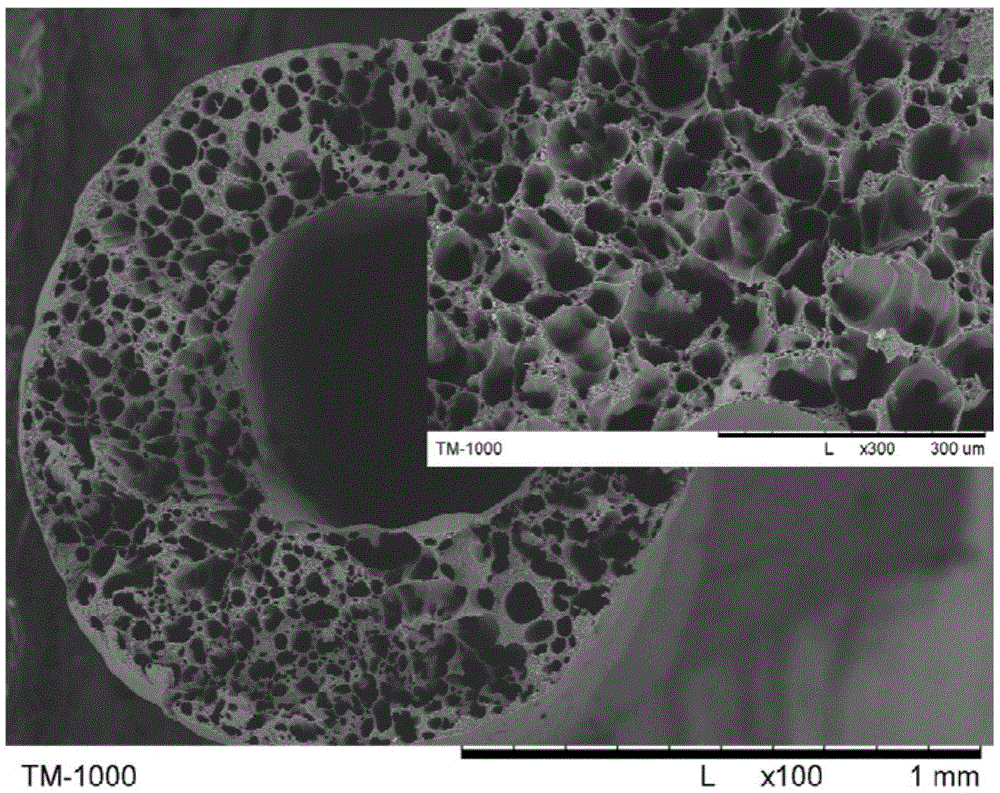

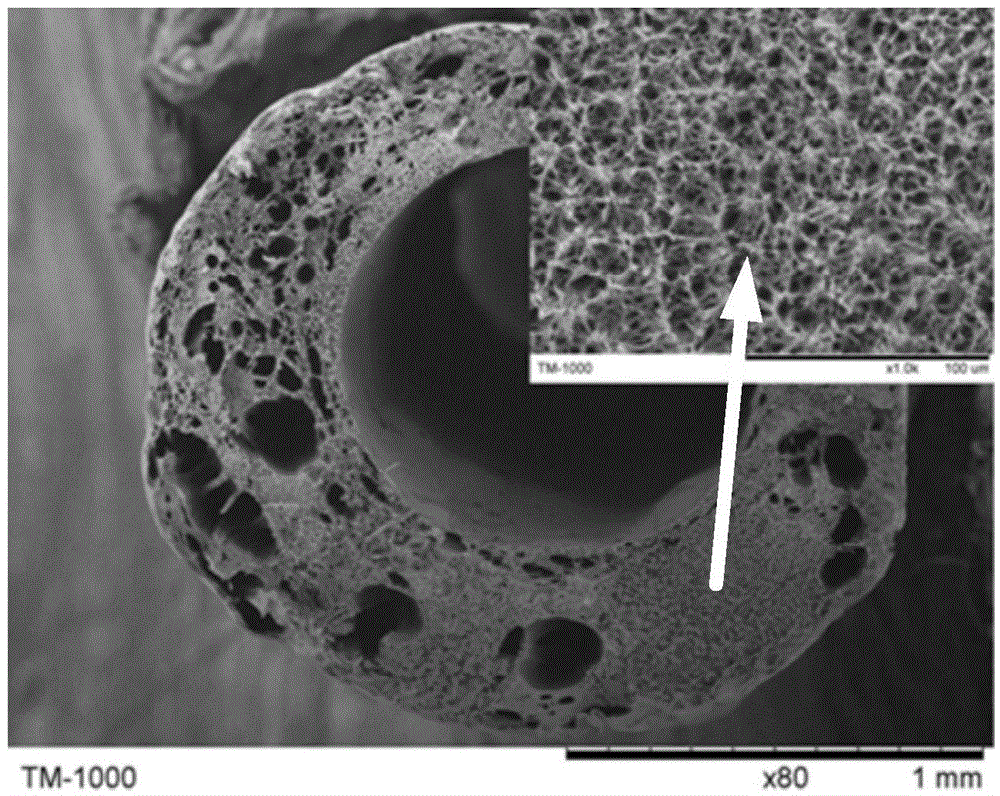

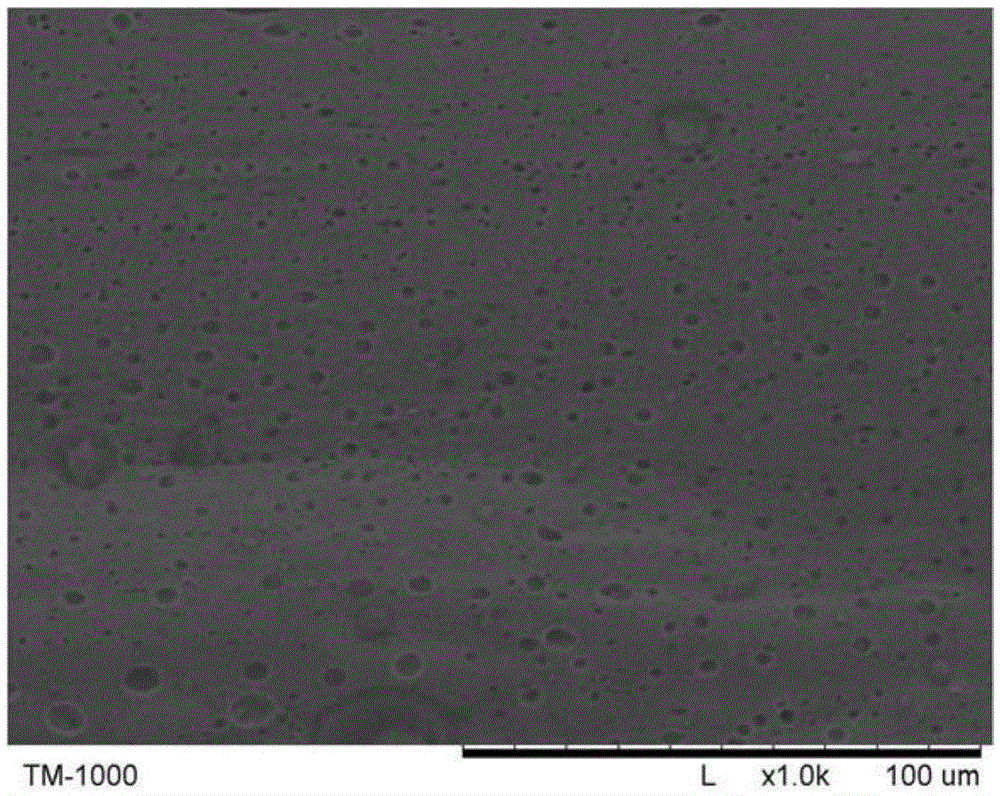

Image

Examples

Embodiment 1

[0031] Step 1: Mix 1700g polyperfluoroethylene propylene, 50g nano-calcium carbonate, and 250g boron nitride fiber in a high-mixer to obtain a mixture.

[0032] Step 2: Turn on the heating system of the twin-screw extruder, heat up and preheat for 2 hours, and the processing temperature is as follows:

[0033]

[0034] Step 3: Feed the mixture into the first zone of the twin-screw extruder at a speed of 5kg / h. After being transported and melted and plasticized in the first two zones, add supercritical carbon dioxide with a temperature of 60°C and a pressure of 10MPa in 3.5ml The speed of / min is injected into the barrel in the third zone.

[0035] Step 4: Under the action of high temperature, high pressure and strong shear force, supercritical carbon dioxide and polymer form a co-fusion system. By adjusting the melt pump, the pressure behind the pump reaches 14.6MPa, and the head quickly releases the pressure.

[0036]Step 5: Extrude through the die, form in a pure water b...

Embodiment 2

[0039] Step 1: Mix 750g polyperfluoroethylene propylene, 30g polytetrafluoroethylene, 10g zinc oxide, 140g sodium chloride and 70g polyethylene oxide in a high mixer to obtain a mixture.

[0040] Step 2: Turn on the heating system of the twin-screw extruder, heat up and preheat for 2 hours, and the processing temperature is as follows:

[0041]

[0042] Step 3: Feed the mixture into the first zone of the twin-screw extruder at a speed of 3.5kg / h. After being conveyed in the first two zones and melted and plasticized, supercritical carbon dioxide with a temperature of 60°C and a pressure of 10MPa is fed in 2ml The speed of / min is injected into the barrel in the third zone.

[0043] Step 4: Under the action of high temperature, high pressure and strong shear force, the supercritical carbon dioxide and the polymer form a co-fusion system. By adjusting the melt pump, the pressure behind the pump reaches 5.8MPa, and the head pressure reaches 12.5MPa, and the pressure is quickly...

Embodiment 3

[0047] Step 1: Mix 740g polyfluoroethylene propylene, 50g polyether ketone ketone, 10g zinc oxide, 140g boron nitride fiber, 50g polyvinylpyrrolidone and 10g triethyl phosphate in a high mixer.

[0048] Step 2: Turn on the heating system of the twin-screw extruder, heat up and preheat for 2 hours, and the processing temperature is as follows:

[0049]

[0050] Step 3: Feed the mixed material into the first zone of the twin-screw extruder at a speed of 5kg / h. After being transported and melted and plasticized in the first two zones, supercritical carbon dioxide with a temperature of 60°C and a pressure of 10MPa is fed at a rate of 3ml / The speed of min is injected into the barrel in the third zone.

[0051] Step 4: Under the action of high temperature, high pressure and strong shear force, supercritical carbon dioxide and polymer form a co-fusion system. By adjusting the melt pump, the pressure in front of the pump reaches 5.8MPa, and the head pressure reaches 12.5MPa, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com