Method for preparing double-color foamed sheet based on temperature control

A foamed sheet and temperature control technology, applied in the foaming field, can solve the problem of additionally introducing adhesives and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: A method for preparing a two-color foamed sheet based on temperature control

[0057] This embodiment provides a method for preparing a two-color foamed sheet based on temperature control, including the following steps:

[0058] Step 1: Put the foamed mother board into the mold cavity of the foaming mold, and raise the temperature in the mold cavity to the first saturation temperature T 1 ;

[0059] Step 2: Inject the foaming agent and heat up to the first saturation temperature T 1 In the mold cavity, so that the foaming agent is at the first saturation temperature T 1 Dissolved into the foamed mother board;

[0060] Step 3: Wait for the foaming agent to reach the first saturation temperature T in the foaming mother board 1 After the saturation state under, the temperature in the mold cavity is raised to the second saturation temperature T 2 and maintain a preset length of time t 2 , so that the foamed mother board forms a temperature gradient in the t...

Embodiment 2

[0089] Embodiment 2: a kind of foam mold

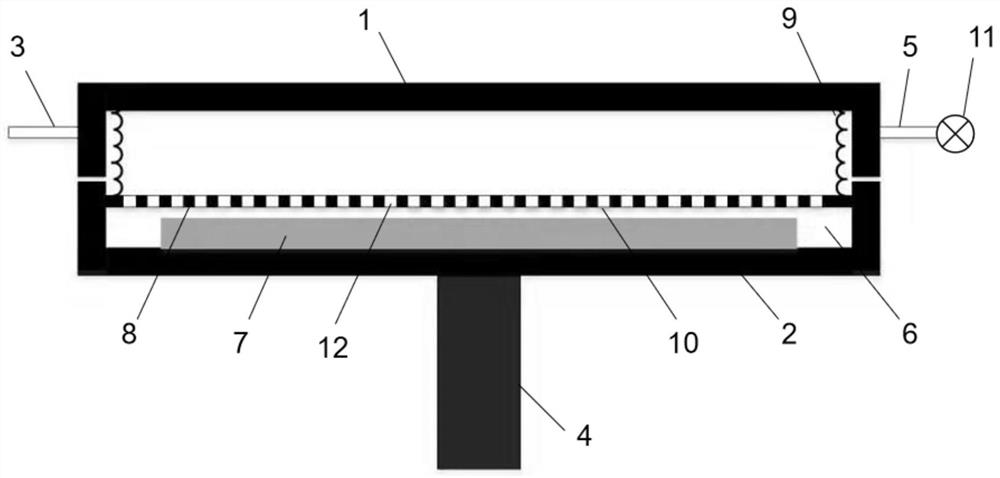

[0090] Such as figure 1 As shown, the present embodiment provides a foaming mold for realizing the method described in Example 1. The foaming mold includes a fixed mold 1 and a moving mold 2; when the fixed mold 1 and the moving mold 2 are closed, both The inner space forms a mold cavity 6, and the mold cavity 6 is used to place a foaming mother board 7; a height control device 8 is provided in the mold cavity 6; the height control device 8 includes a driving member 9 and a moving plate 10; The driving member 9 can drive the moving plate 10 to move in the mold cavity 6 along the thickness direction of the foaming mother board 7 , so that the moving board 10 is attached to the foaming mother board 7 .

[0091] As preferably, the foaming mold also includes an injection pipeline 3, a pressure control device 4 and a pressure relief pipeline 5; channel; the pressure control device 4 applies pressure to the movable mold 2 so that the mold...

Embodiment 3

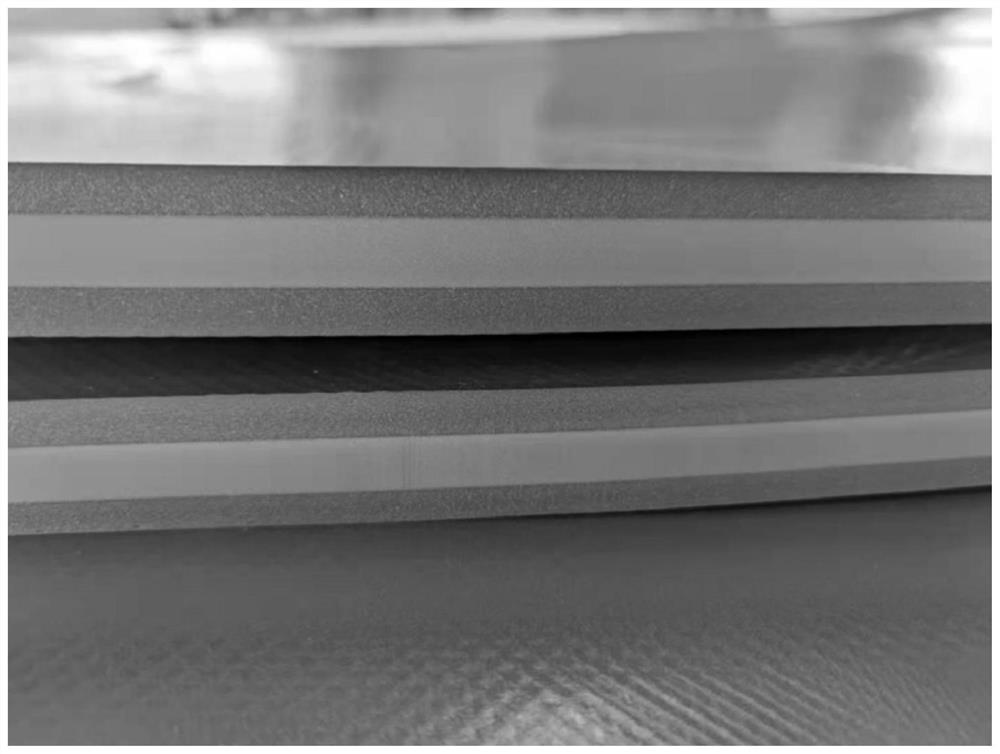

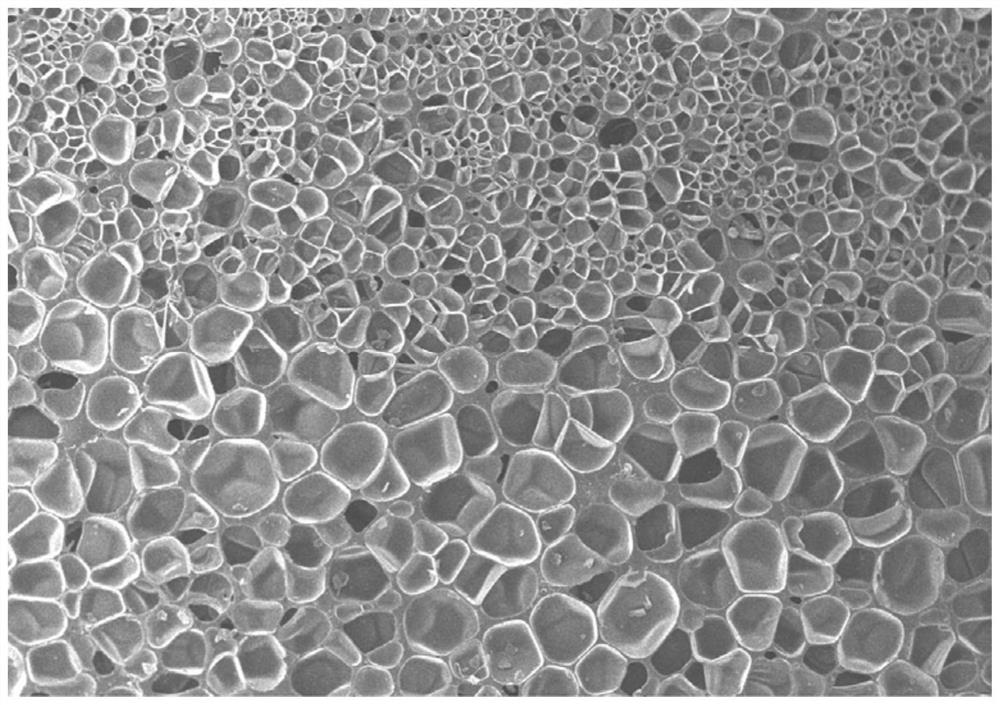

[0097] Example 3: Application of the method described in Example 1 in the preparation of two-color foamed sheet

[0098] This embodiment provides the application of the method described in Example 1 in the preparation of two-color foamed sheets, and the application uses the foaming mold described in Example 2 (the size of the mold cavity 6 of the foaming mold is 1000mm long * wide 800mm * high 50mm) to foam the foamed mother board, and use a TPU (thermoplastic polyurethane elastomer rubber) solid plate with a length of 500mm*width 300mm*thickness of 10mm as the foamed mother board (Tg=-40°C, Shore hardness 80A), specifically Including the following steps:

[0099] Step 1: After putting the foamed mother board into the mold cavity of the foaming mold, use the telescopic screw rod to control the moving plate to move in the mold cavity along the thickness direction of the foamed mother board. After the combination, the mold cavity and the moving plate are heated by program tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com