Selecting and packing method of catalyst for sulphur recovery

A catalyst and filling technology, applied in the preparation/purification of sulfur, etc., can solve the problems of complex components, large gas volume fluctuations, low efficiency, etc., and achieve the effects of avoiding pollution, controlling environmental pollution, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

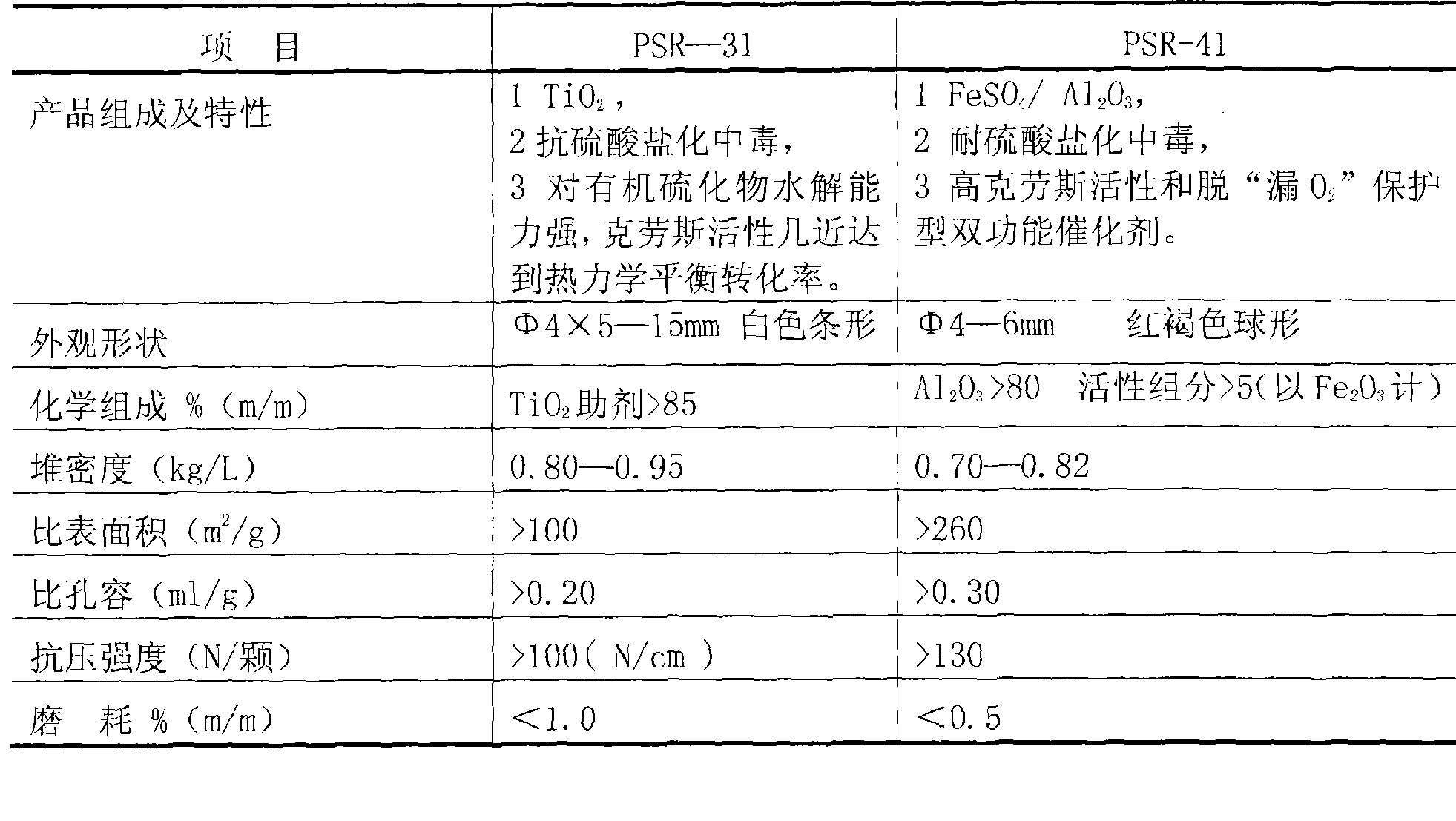

[0012] A method for filling sulfur-making catalysts in the rubber additive industry, characterized in that the three-stage sulfur-making reactors are filled with sulfur-making catalysts, and the height of the catalysts in the three-stage sulfur-making reactors is 800mm; the upper part of the first-stage converter is filled with 1m 3 PSR-41, lower filling 2m 3 PSR-31; fill 1.1m in the upper part of the secondary converter 3 PSR-41, lower filling 2.1m 3 PSR-31; fill 1.6m in the upper part of the three-stage converter 3 PSR-41, lower filling 1.6m 3 The PSR-31.

[0013] The selection and filling method of the novel sulfur-making catalyst provided by the present invention is based on the CS in the acid gas produced by the rubber vulcanization accelerator MBTS in the rubber industry. 2 The characteristics of high content, the selection of extremely high COS / CS 2 Catalysts with hydrolytic activity, large specific surface area and pore volume, which have increased the area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com