Reticule thickness measuring instrument

A tester and marking technology, applied in the field of marking thickness tester, can solve the problems of large human error, troublesome operation, large error in test accuracy, and achieve the effect of reducing confusion and potential safety hazards, easy operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

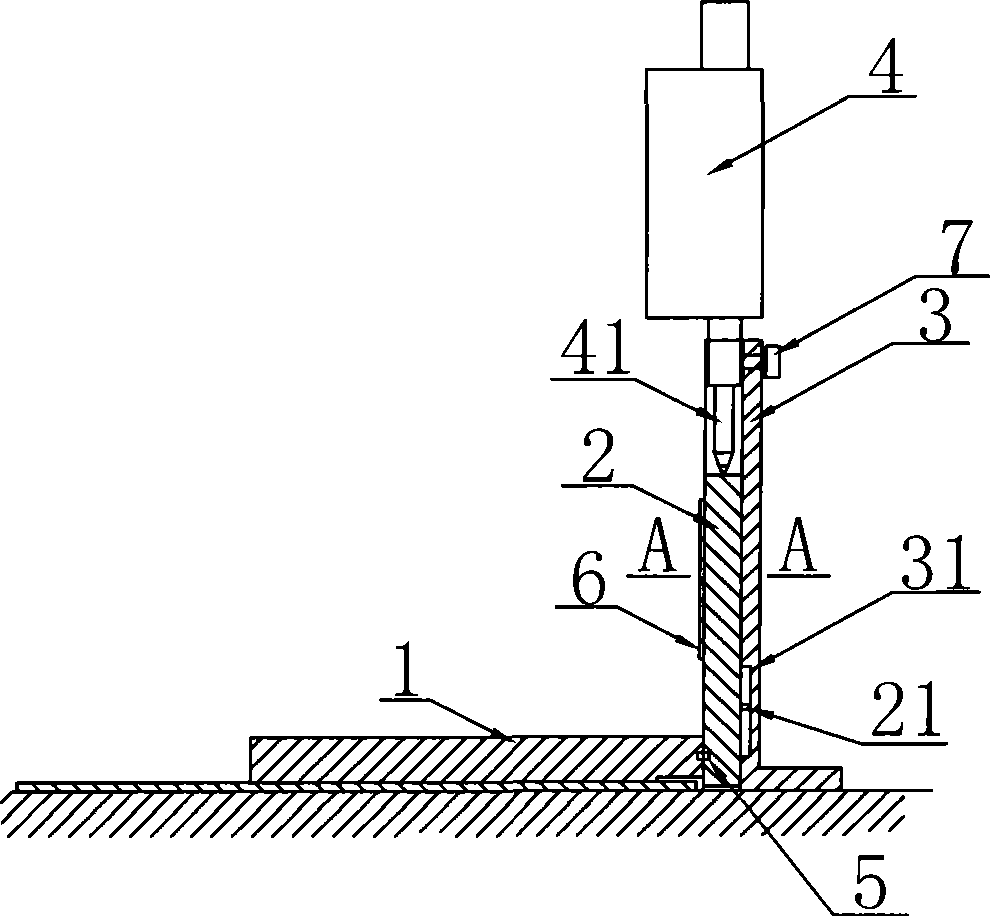

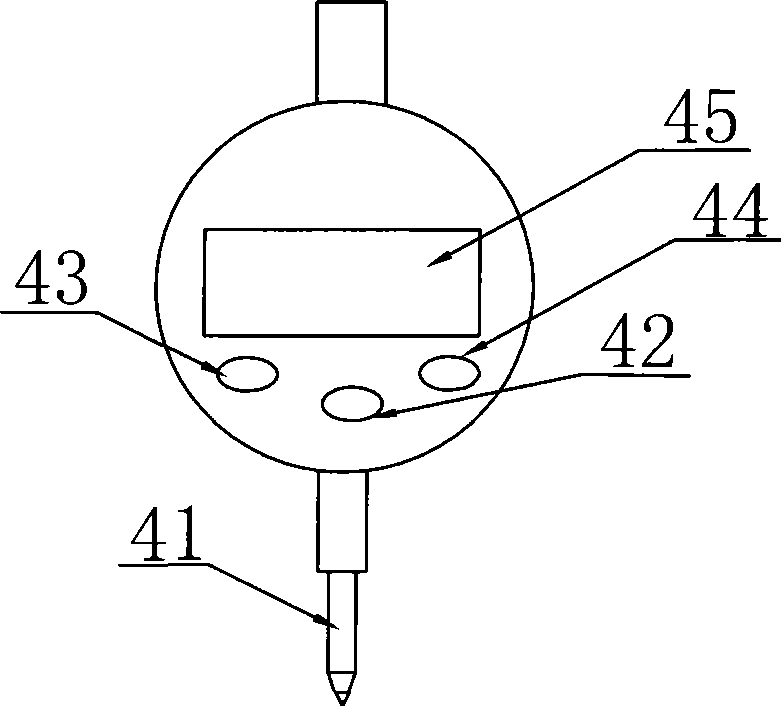

[0018] Such as figure 1 , figure 2 , Figure 5 It is the first embodiment of a marking line thickness tester of the present invention, including a movable measuring platform 1, a sliding column 2, a column 3, and a high-precision measuring gauge 4, and the high-precision measuring gauge 4 is a high-precision digital display dial indicator , the movable measurement platform 1 is connected to the side wall of the sliding column 2, a chute is provided in the column 3, the sliding column 2 is arranged in the chute, the high-precision measuring table 4 is fixed on the column 3, and the high The measuring head 41 of the accuracy measuring table is in close contact with the column head of the sliding column 2, and the movable measuring platform 1 and the sliding column 2 are flexibly connected through a rotating device; the rotating device is a hinge pin 5, and the chute in the column 3 The cross section is rectangular, and the sliding column 2 is compatible with the chute, and th...

Embodiment 2

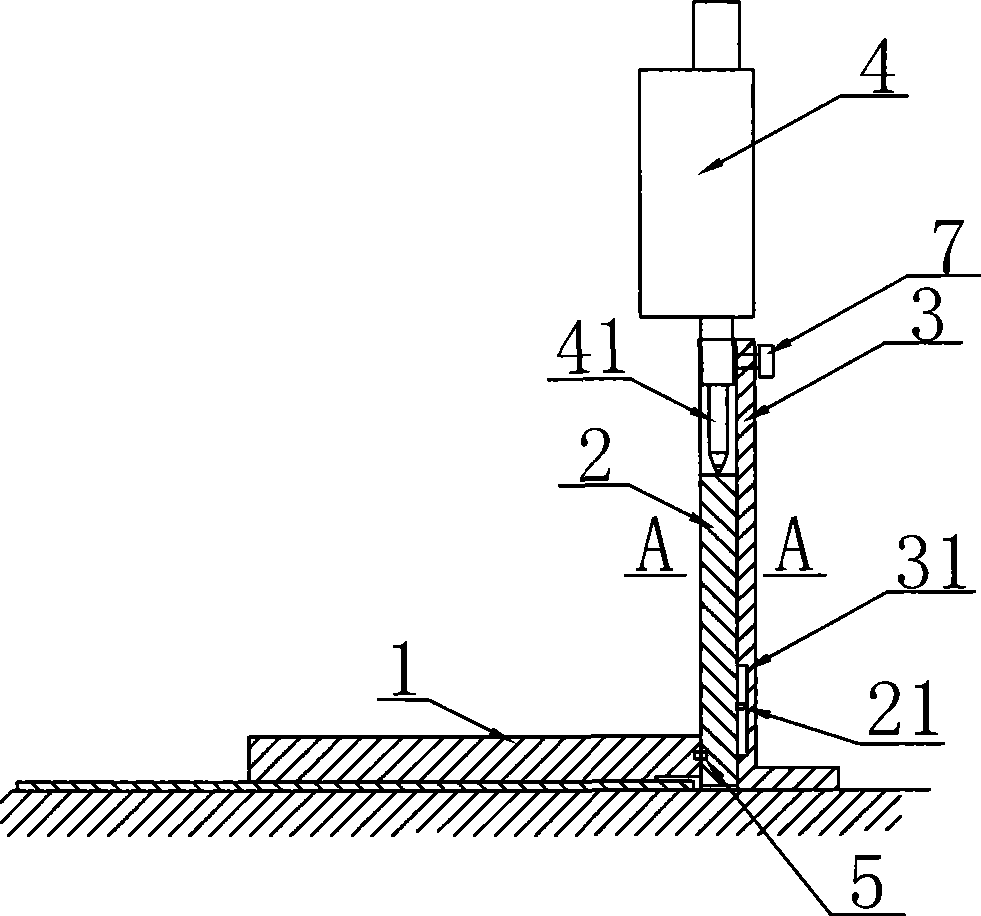

[0021] Such as image 3 , Figure 4 , Figure 5 It is the first embodiment of a marking line thickness tester of the present invention, including a movable measuring platform 1, a sliding column 2, a column 3, and a high-precision measuring gauge 4, and the high-precision measuring gauge 4 is a high-precision digital display dial indicator , the movable measurement platform 1 is connected to the side wall of the sliding column 2, a chute is provided in the column 3, the sliding column 2 is arranged in the chute, the high-precision measuring table 4 is fixed on the column 3, and the high The measuring head 41 of the accuracy measuring table is in close contact with the column head of the sliding column 2, and the movable measuring platform 1 and the sliding column 2 are flexibly connected through a rotating device; the rotating device is a hinge pin 5, and the chute in the column 3 is The dovetail groove, the sliding column 2 is matched with the sliding channel, the sliding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com