Balancing arrangement method on cutterhead for positive hobbing cutter and transition hobbing cutter

A layout method and transition rolling technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problem of difficult determination of position parameters, and achieve the effects of improving reliability and operating life, improving operating environment, and reducing vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

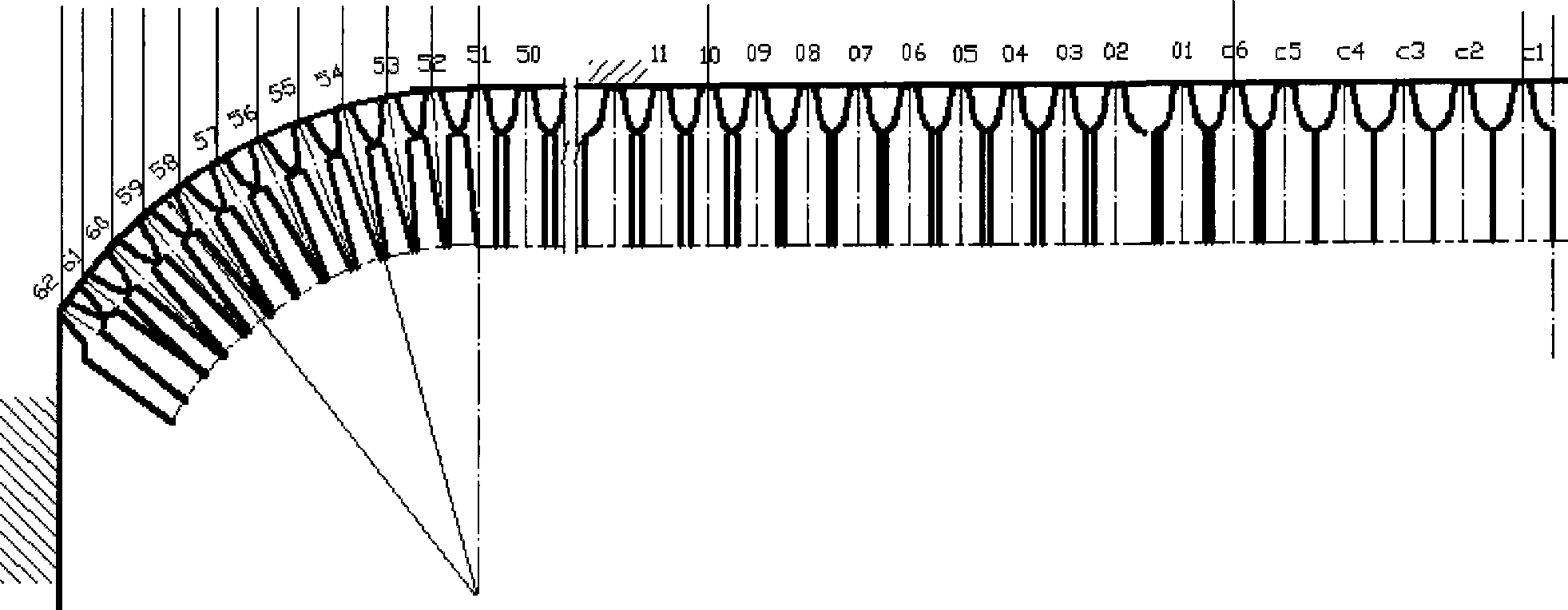

[0037] The maximum cutter spacing S of the disc-shaped hob on the tunnel boring machine cutter head determined according to a specific operation object max =90mm, a total of 62 positive hobs and transitional disc hobs are installed on this cutter head, S 1 ~S 10 70mm, S 11 ~S 51 65mm, S 52 =63mm, S 53 =61mm, S 54 =62mm, S 55 =59mm, S 56 =57mm, S 57 =55mm, S 58 =52mm, S 59 =50mm, S 60 = 44mm, S 61 =39mm,S 62 =31mm, the installation radius of the outermost center knife is 462mm, then ρ i = 462 + Σ i = 1 i S i .

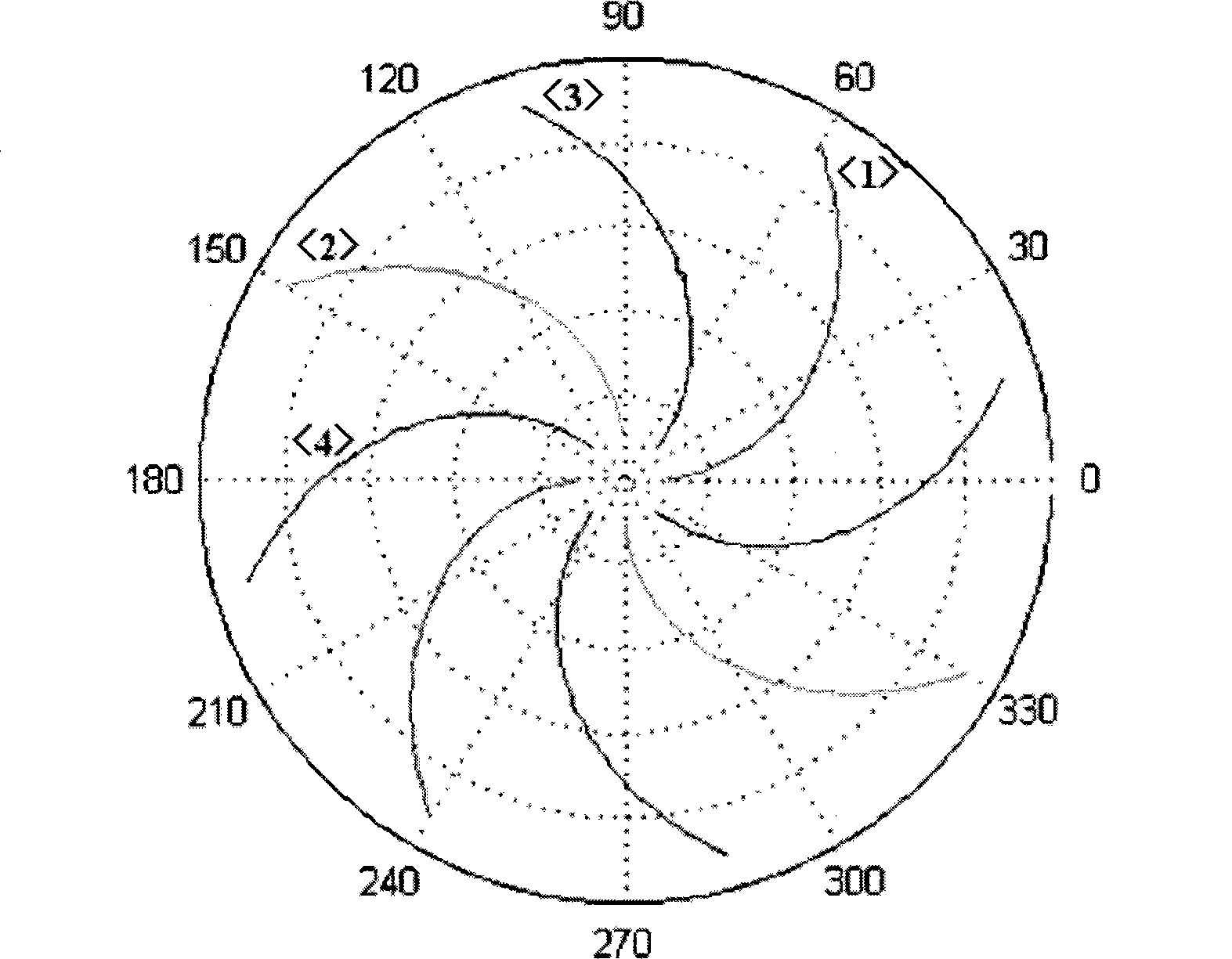

[0038] Take l=4, μ=π / 3, and establish the auxiliary equation: R = 462 + π 3 ( θ - k ...

Embodiment 2

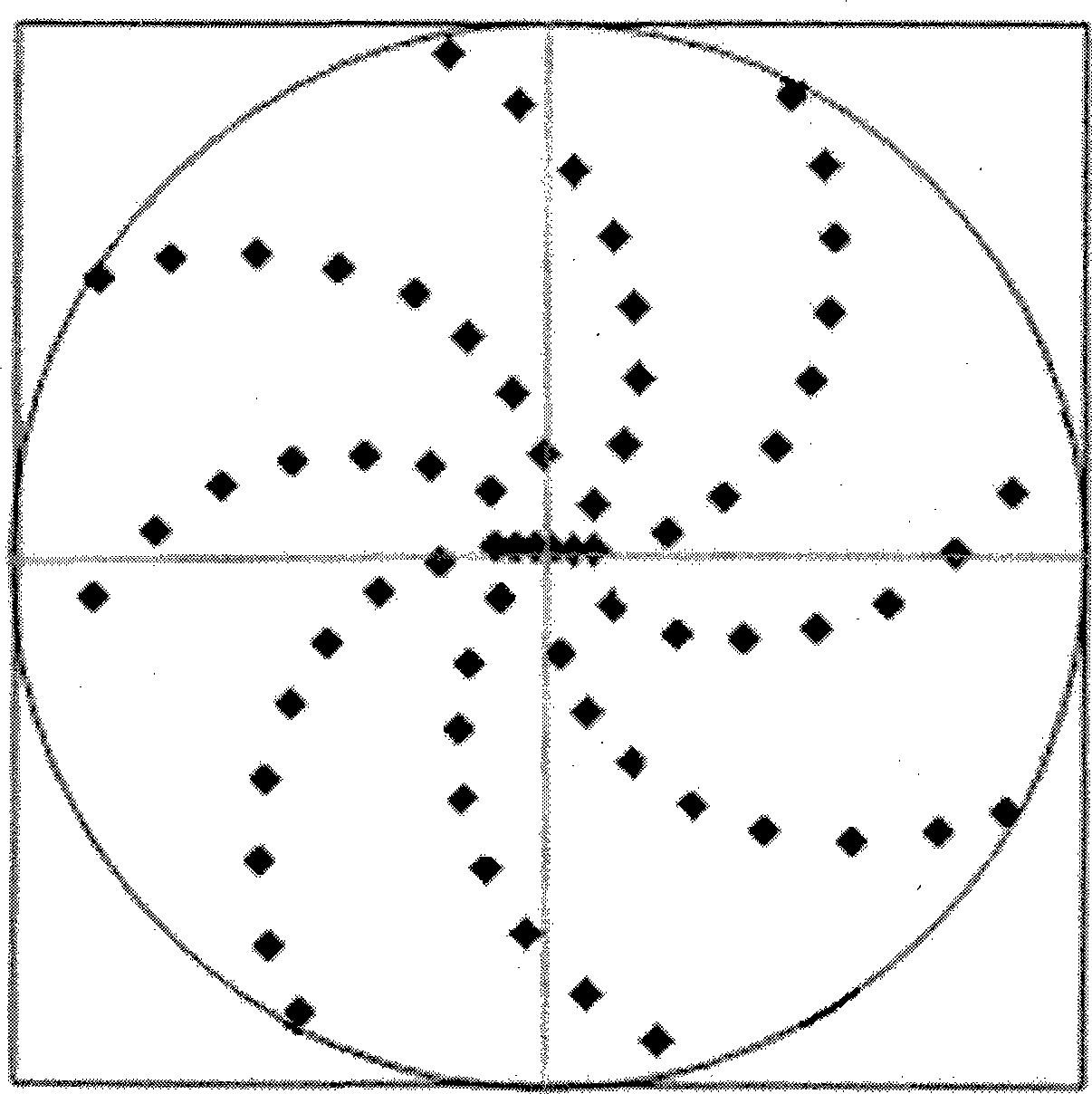

[0040] set auxiliary equation R = R 0 + μ ( θ - k · π l ) Among μ=2π / 3, all the other parameters are identical with embodiment 1, and the arrangement of disc-shaped hob on the cutter head is as attached Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com