Full-ring steel tunnel segment structure with seal protection door

A protective door and segment technology, which is applied in the shaft lining, tunnel lining, underground chamber, etc., can solve the problems of high risk of construction communication channels, inability to prevent soil, water gushing, and no airtight safety protection structure, etc., to shorten the construction period, Easy assembly, ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

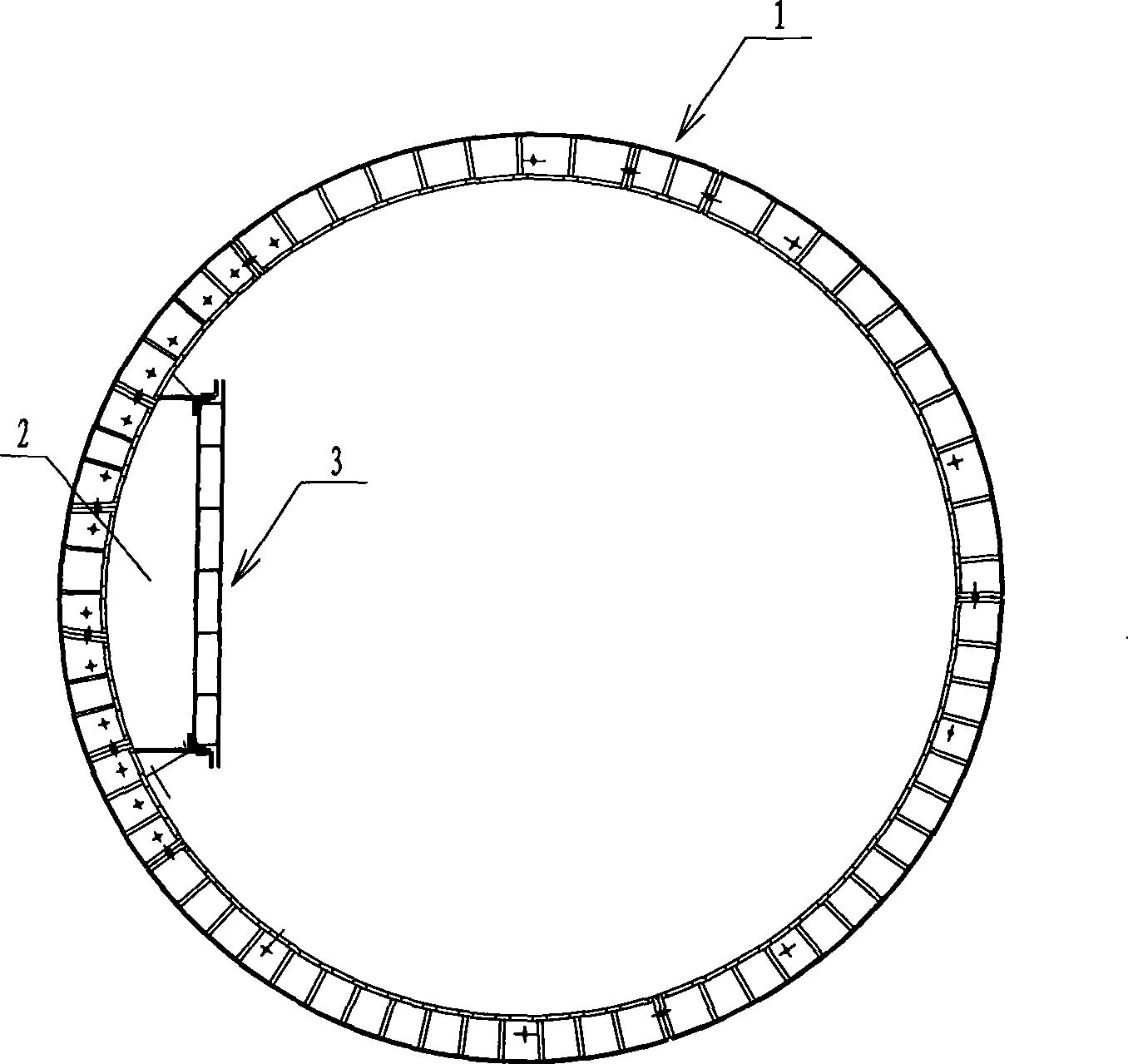

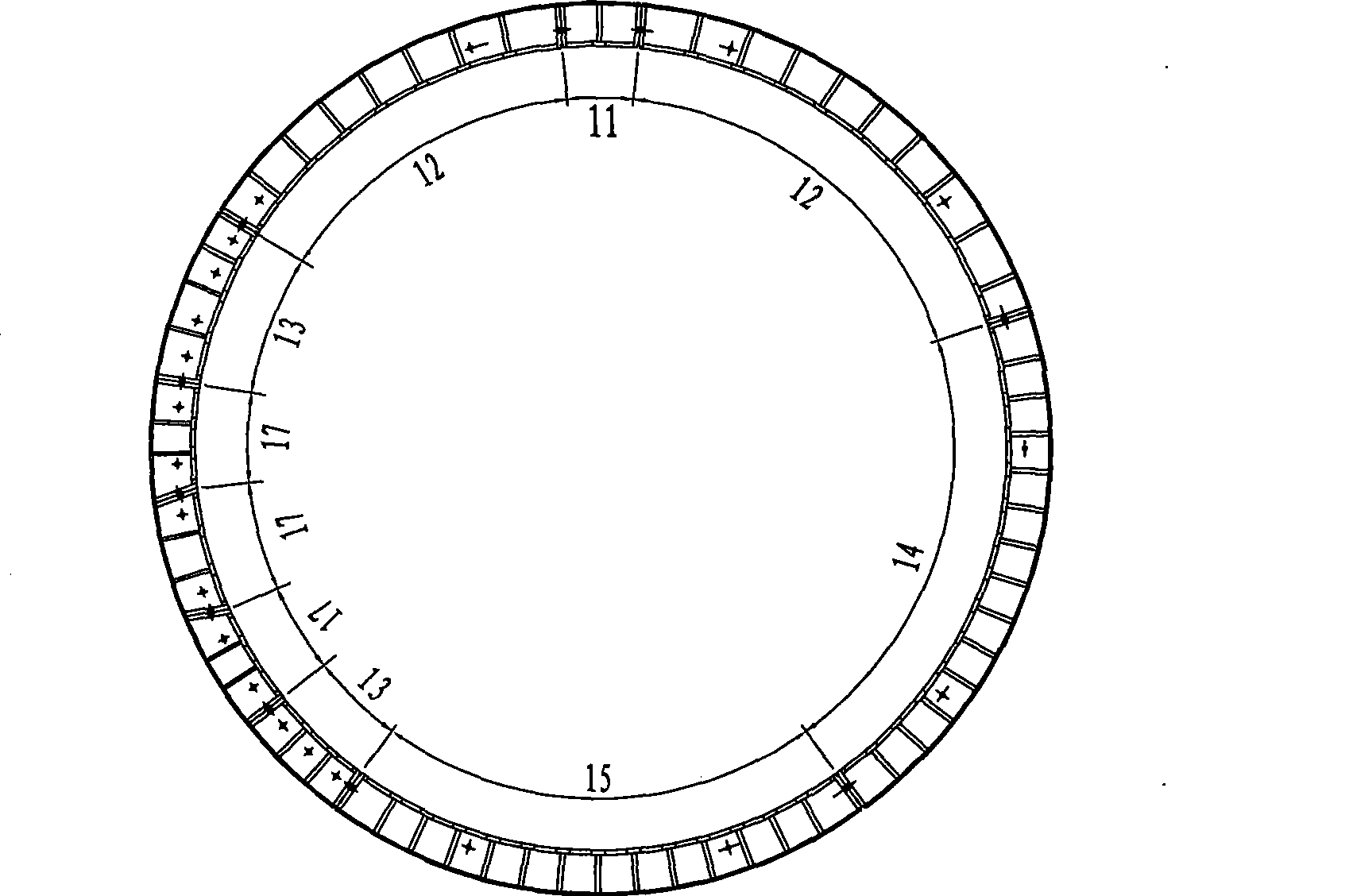

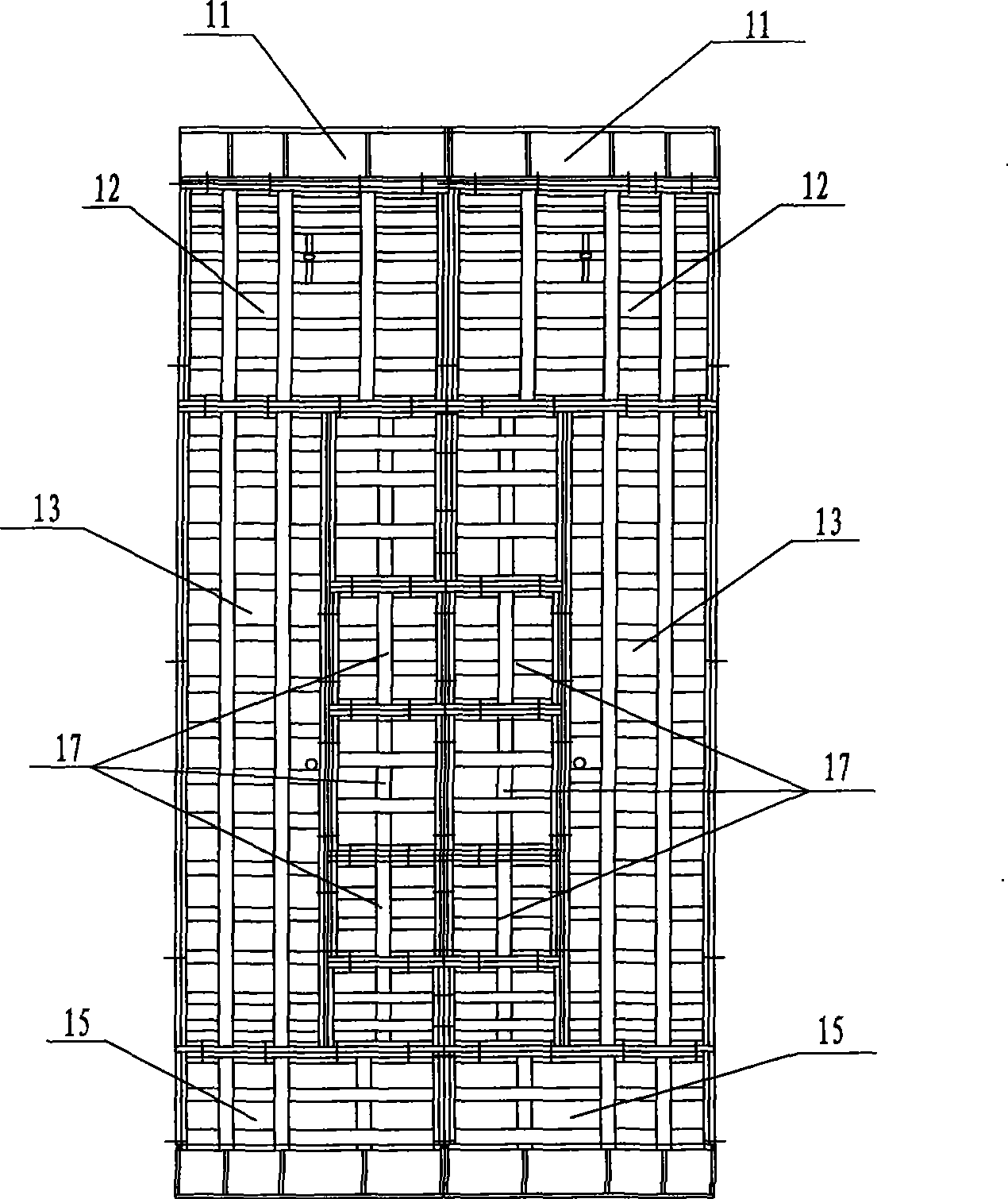

[0050] like Figure 1 to Figure 20 Shown is a full-ring steel segment structure with a closed protective door, which has a full-ring steel segment frame 1, and the full-ring steel segment frame 1 is assembled from a main frame and a detachable frame. The steel segment structure also has a protective door 3, which is located in the full-ring steel segment frame 1, which is fixedly installed on the main frame, and the installation position is at a corresponding position with the detachable frame. The protective door 3 and The area surrounded by the detachable frame forms an airtight chamber 2. After the protective door 3 is closed, the airtight chamber 2 is airtight and impermeable, which can prevent soil and gushing water from entering the shield tunnel.

[0051]The main frame of the full-ring steel segment frame 1 is a ring structure with side openings, which is assembled from multiple steel segment blocks, and the multiple steel segment blocks are respectively the capping ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com