Rotating valve mechanism for internal combustion engine

A technology of rotary valve and internal combustion engine, applied in the field of rotary valve mechanism of internal combustion engine and rotary valve device, can solve the problems of insufficient ventilation, poor practicability, increased extra power consumption, etc., and achieve smooth intake and exhaust, smooth ventilation, controllable The simple and direct effect of the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

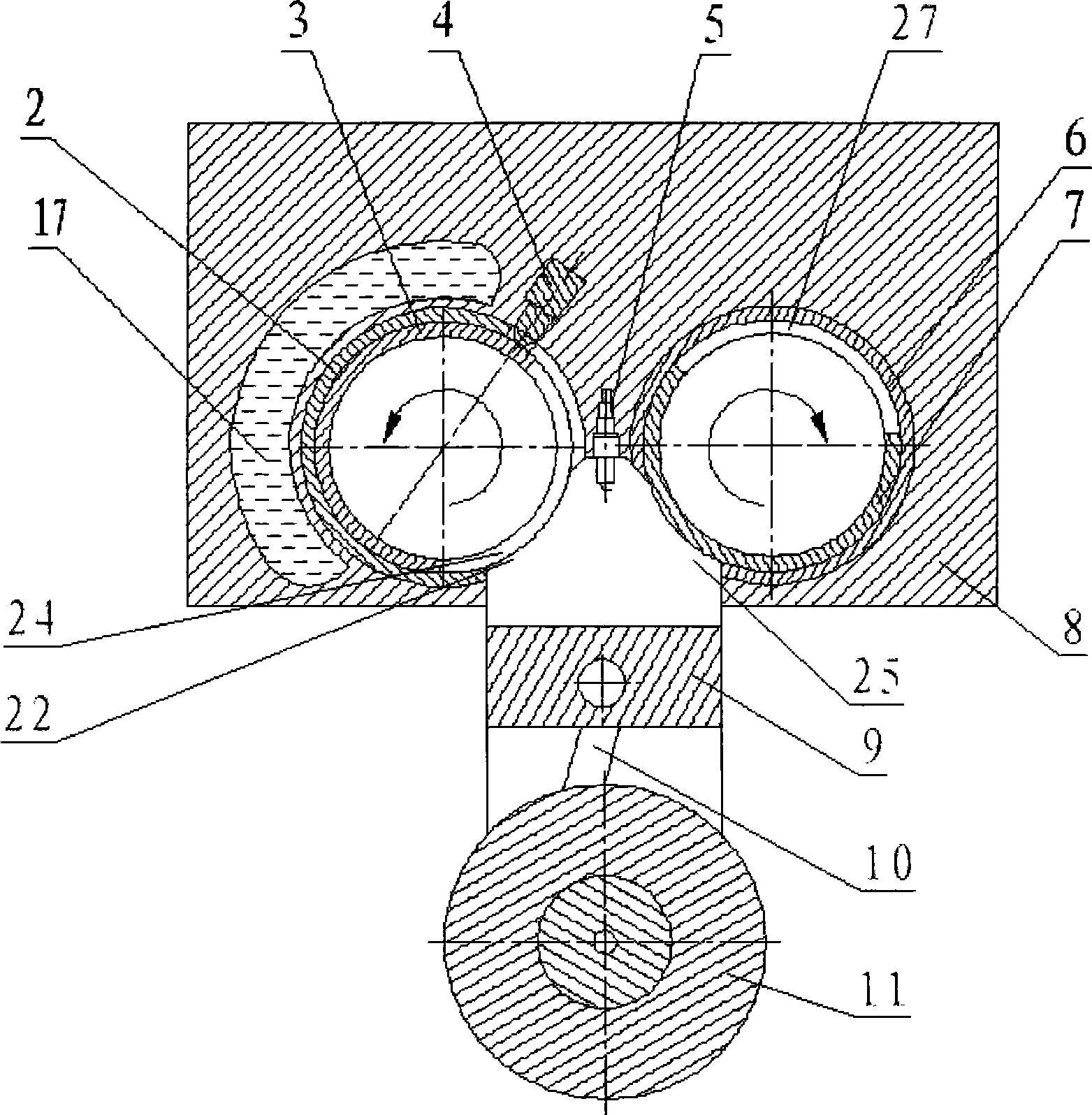

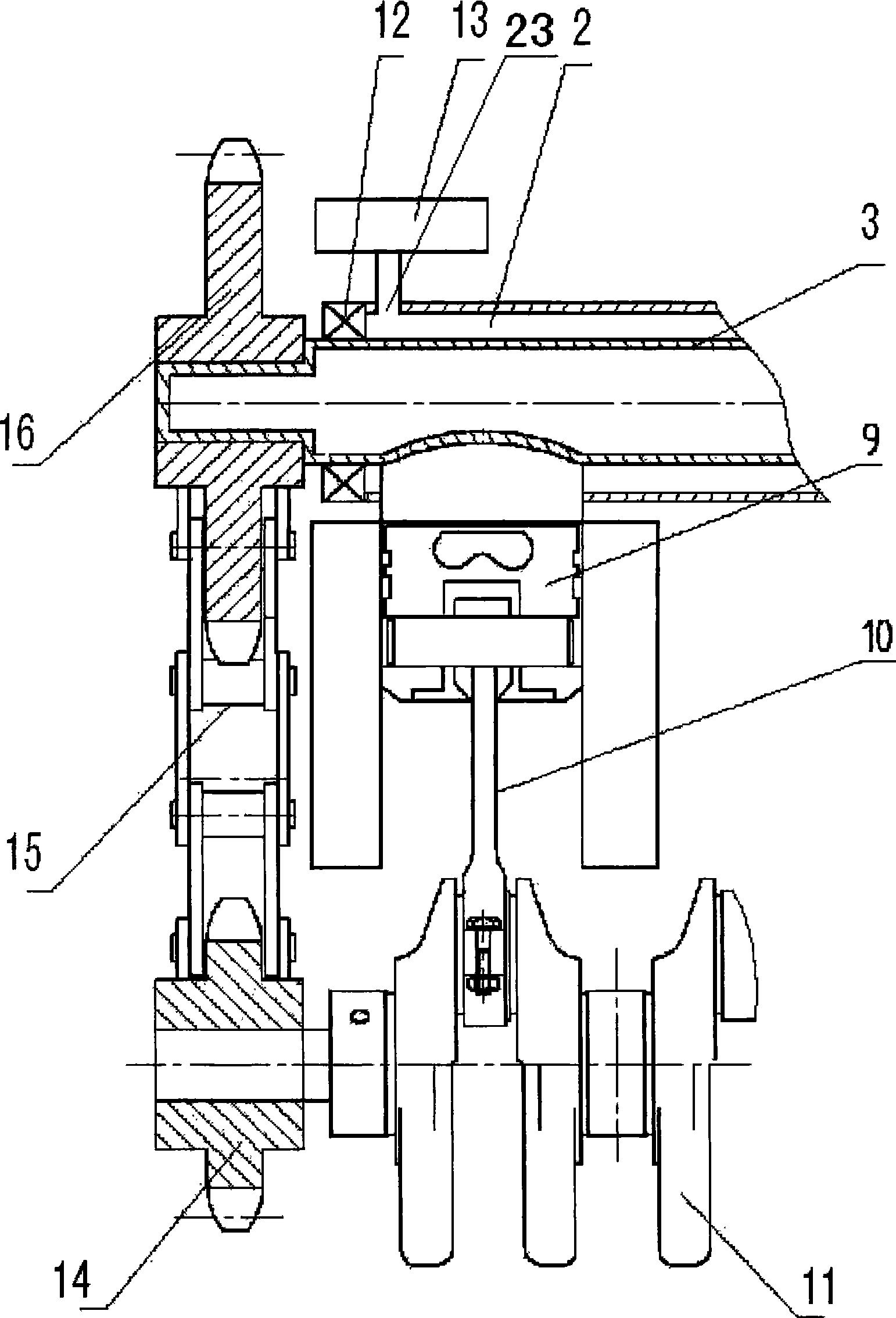

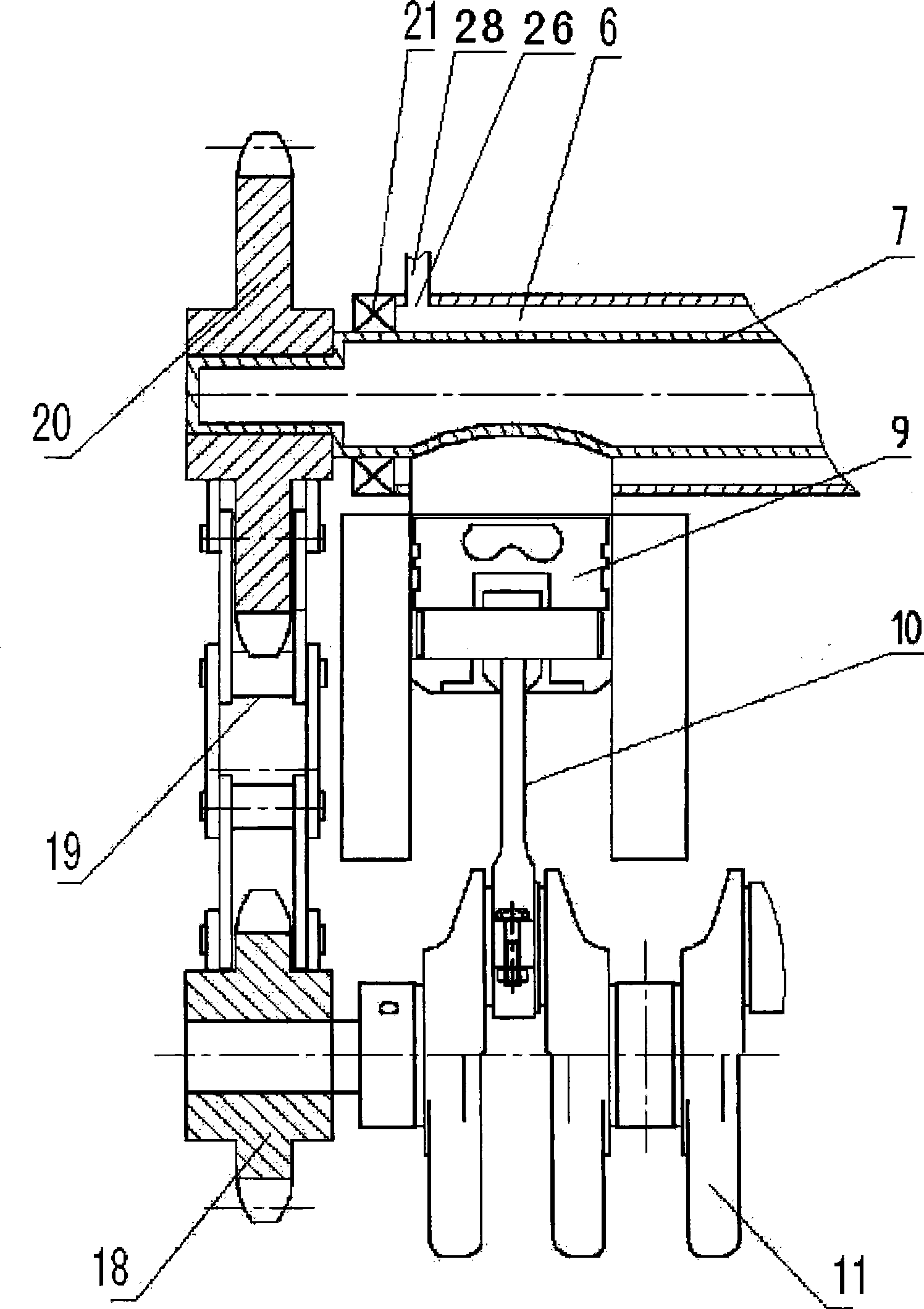

[0028] Embodiment 1: refer to each accompanying drawing.

[0029] A rotary valve mechanism for an internal combustion engine (four-stroke engine), consisting of an intake valve mechanism and an exhaust valve mechanism;

[0030] The intake valve mechanism includes:

[0031] Cylindrical intake pipe 2 (i.e. cylindrical, tubular intake pipe), the intake pipe 2 is fixedly connected or integrated with the cylinder head 8 of the internal combustion engine, closed at both ends, and communicated with the combustion chamber 1 on the cylinder head The hole 22 (its shape is preferably the hole of the cross-sectional shape of the intake pipe and the combustion chamber) and the first air intake hole 23 communicated with the air cleaner 13;

[0032] Cylindrical intake valve 3 (that is: cylindrical, tubular intake valve), the middle section of the intake valve 3 is placed in the intake pipe 2, and has a hole communicating with the intake pipe 2 (so that the intake valve 3 cavity and the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com