Datamation mapping method applying to flat pattern workpieces

A data-based, workpiece-based technology, applied in the field of non-contact data-based surveying and mapping, can solve problems such as large randomness, inability to adapt to optical scanning ritual measurement, and cumbersome operation and use, so as to achieve no need for repeated investment, improve surveying and mapping efficiency, and be easy to promote popular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

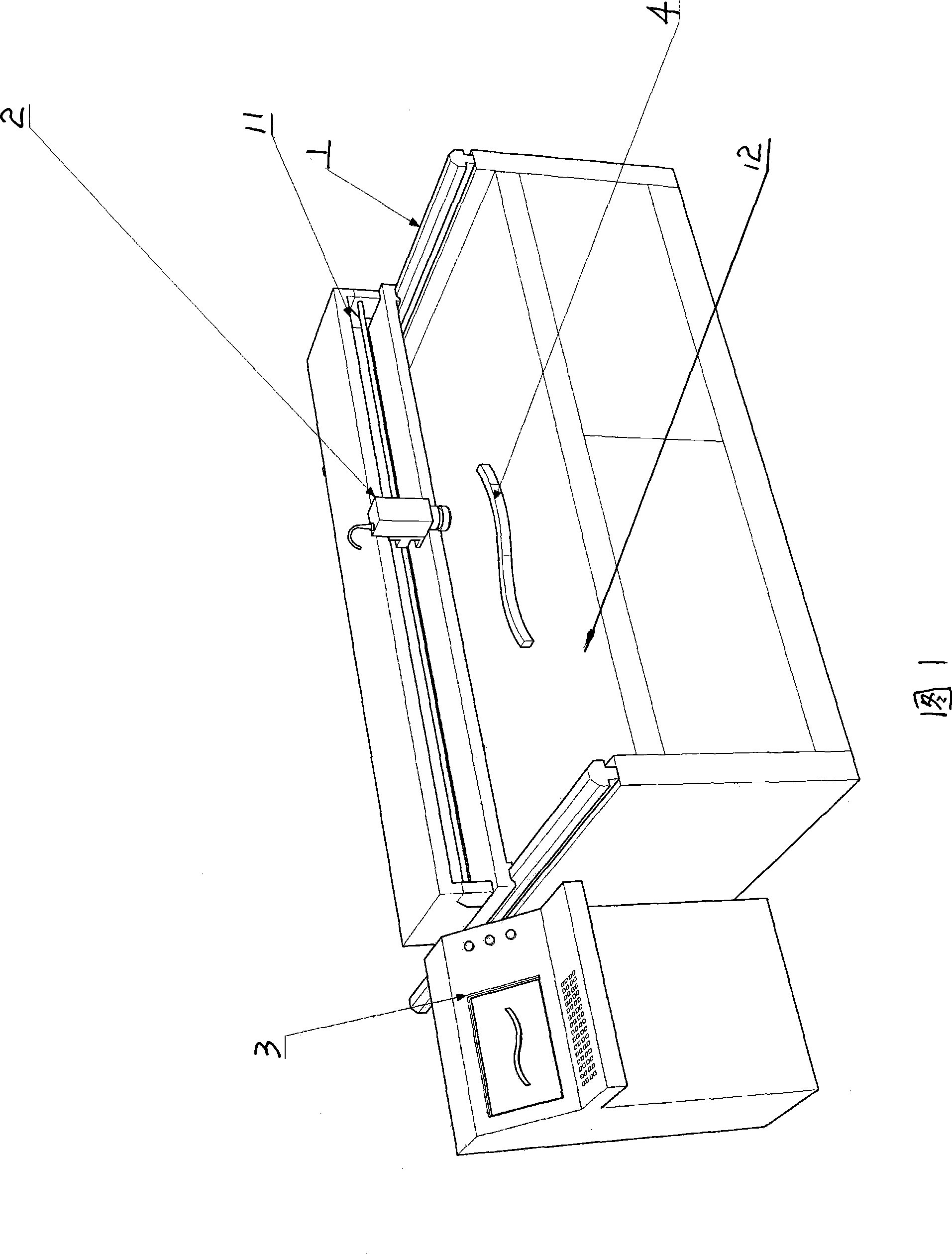

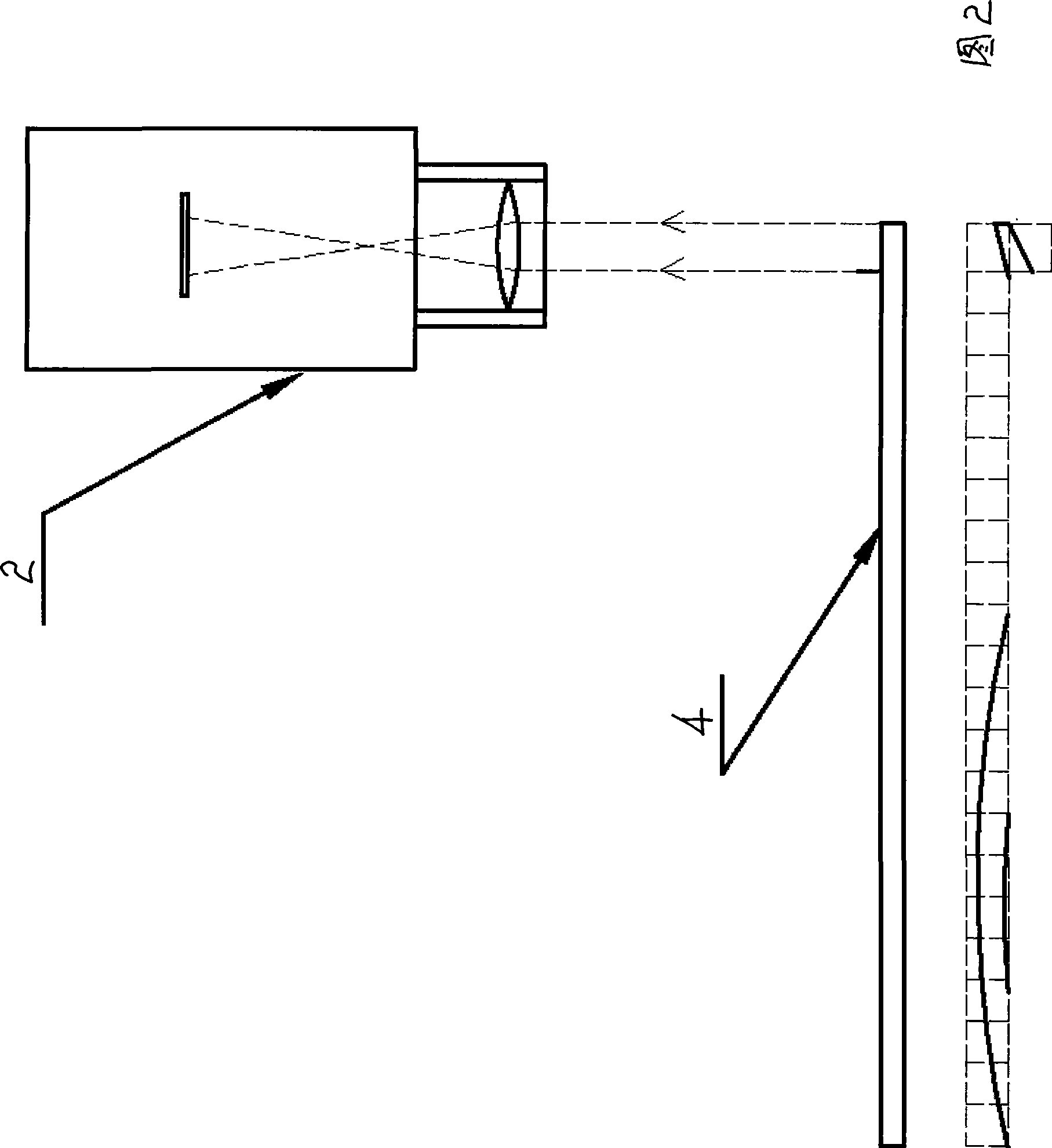

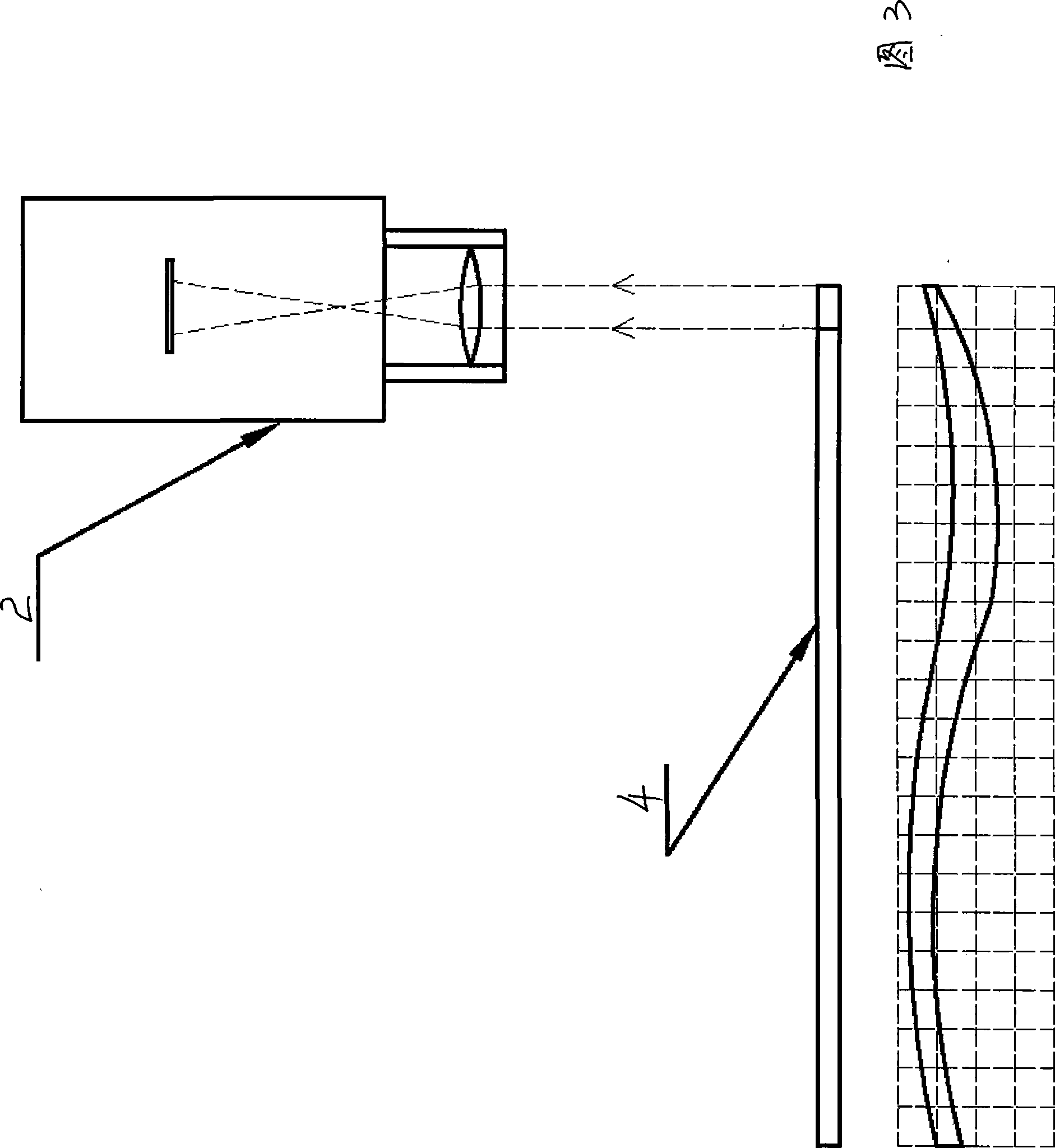

[0019] Embodiment 1, referring to Fig. 1, taking the chair back workpiece parent part of a chair in surveying and mapping woodworking processing as an example, the equipment required for the data-based surveying and mapping method of this embodiment includes a conventional XY platform 1, a conventional camera 2, a conventional Control the PC 3 and known software, the camera 2 is fixed vertically downward on the moving bracket 11 of the XY platform 1 , and the mother part 4 is horizontally placed on the machine table 12 of the XY platform 1 . Before surveying and mapping, first roughly delineate the X-axis and Y-axis travel ranges of the camera 2 on the XY platform 1 according to the length and width dimensions of the parent part 4, which are 1200mm×60mm --- the rectangle surrounded by the X-axis of 1220mm and the Y-axis of 100mm Then move the camera 2 to the initial surveying point and adjust the focus.

[0020] At the beginning of surveying and mapping, the camera 2 first tak...

Embodiment 2

[0021] Example 2, see Figure 4 , the equipment required in this embodiment is similar to that of Embodiment 1, except that it is manually controlled or a manual control handle is added, and the manual control handle is connected to the control system of the XY platform, mainly for those that only have outer contours but no internal lines and shapes. Solid female piece 4'. In order to improve the efficiency of surveying and mapping and save surveying and mapping time, for those solid parent parts 4', only the outer contour shape of the parent part 4' can be photographed without rigidly reciprocating the whole process. Therefore, during surveying and mapping, from Starting from the initial surveying point, the stop point of the camera 2 can be manually controlled, so that the camera 2 can only move and shoot equidistantly along the contour shape of the parent part 4', and then advance along the contour shape of the parent part 4' at equal intervals , until walking back to the i...

Embodiment 3

[0022] Embodiment 3, referring to Fig. 5, the way of camera sampling can be that the camera 2' is fixed at the origin on the machine table, and the workpiece base 4 is driven by the XY platform 1' to perform intervals at equal intervals under the lens of the camera 2' Stepping displacement, PC 3' for software data processing. This can also achieve the technical effect of converting from a master piece to a line drawing in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com