Three-dimensional contour outline measuring set based on multi sensors and measuring method thereof

A three-dimensional contour and multi-sensor technology, applied in the field of optical inspection, can solve the problems of low measurement efficiency of three-coordinate measuring machines, unsuitable for batch inspection of parts, unsuitable for precision parts inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

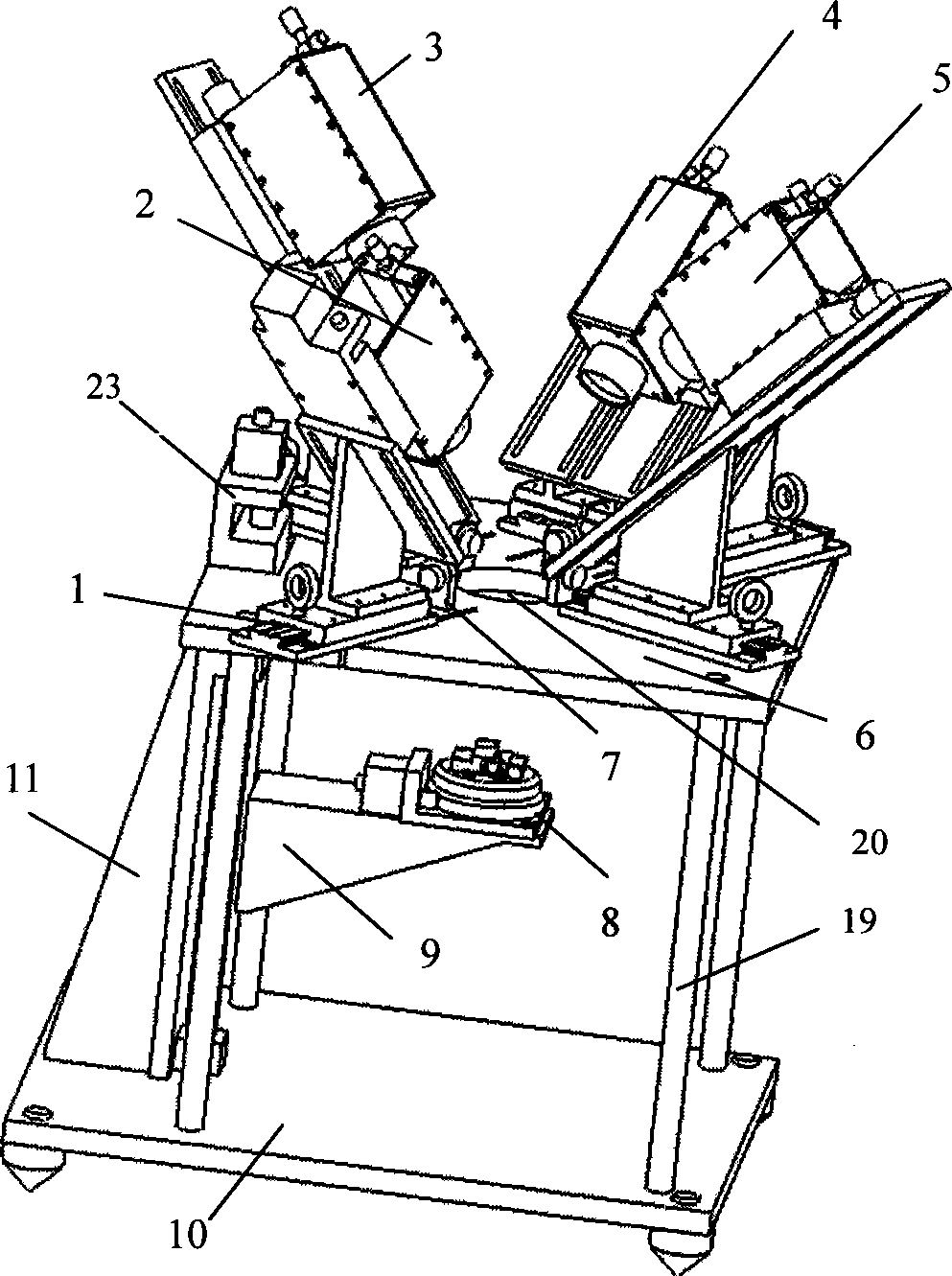

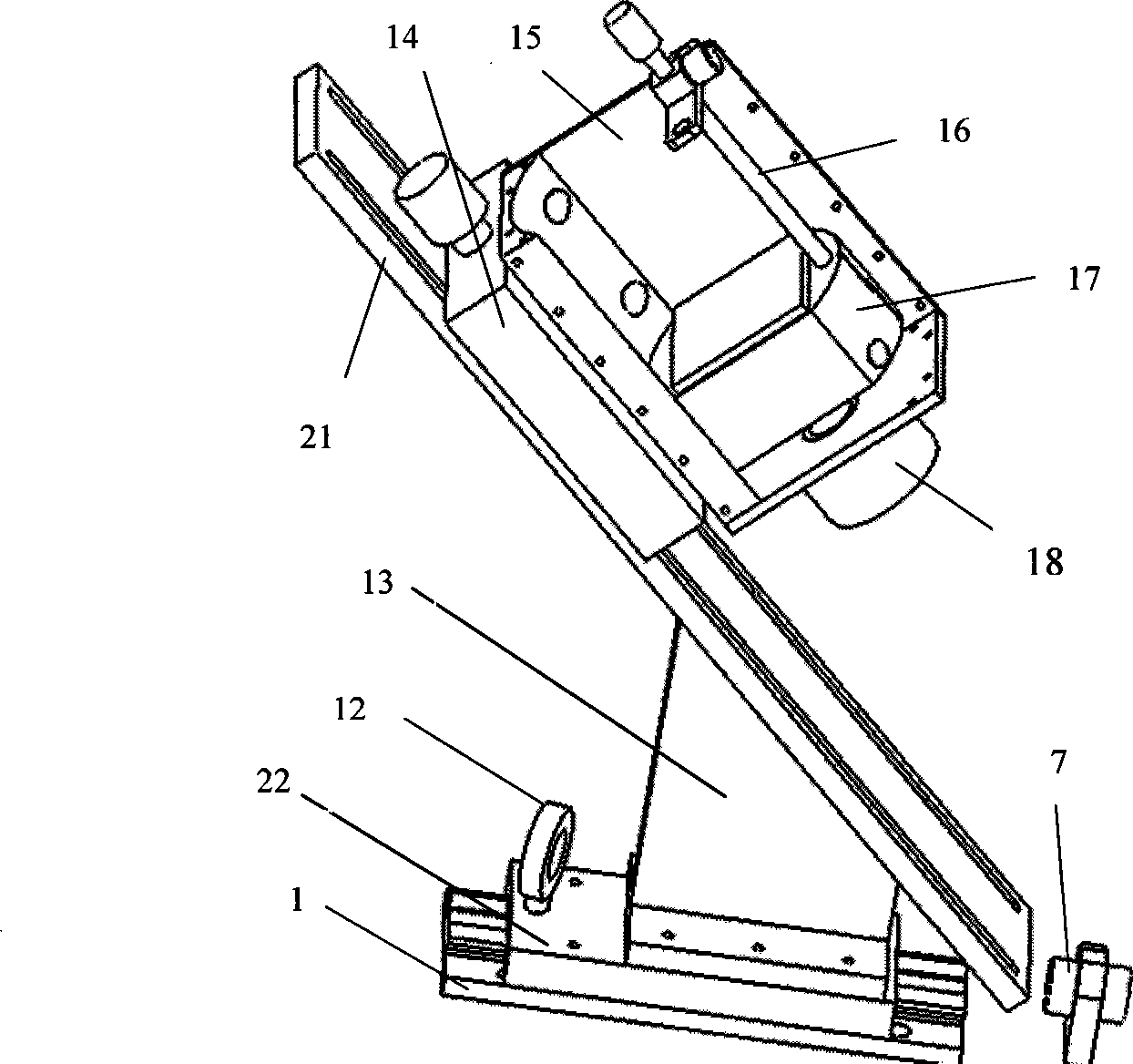

[0060] In the following, the feasibility of the present invention will be analyzed by taking the measurement of the blade profile of an aeroengine as an example. The multi-sensor-based three-dimensional profile measurement device used in this embodiment is as figure 1 A setup with four light-measuring components is shown.

[0061] 1. Before the measurement starts, the following series of preparations need to be done:

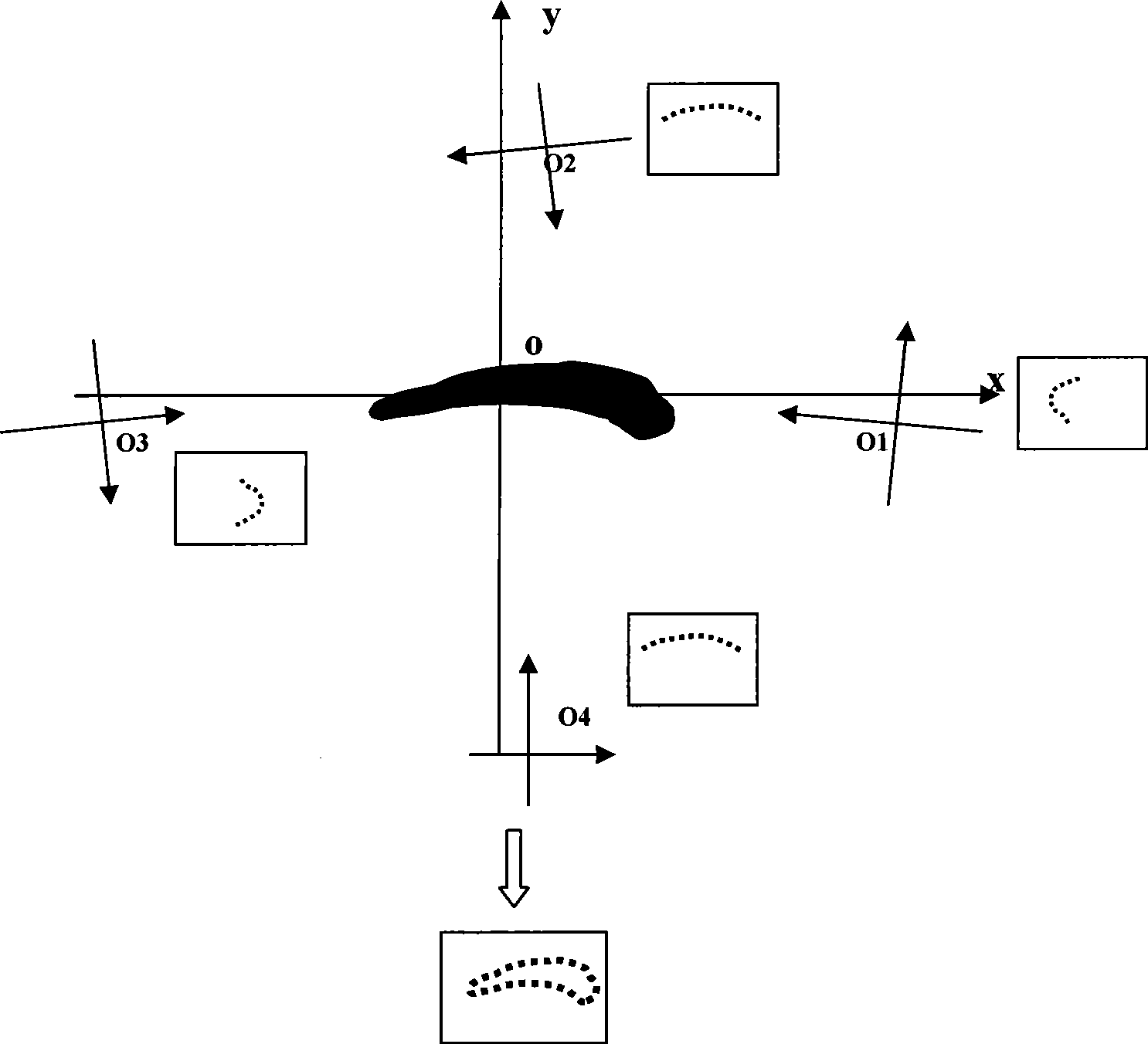

[0062] (1) First adjust the four lasers 7 in the same plane. The specific implementation method is to use the vertical screen to receive the light knives emitted by any two lasers 7. When the receiving screen moves from far to near and from near to far, the two The light knives are always displayed as being on a straight line, at this time we think that the two light knives are already in the same horizontal plane, that is, the laser 7 is also in the same horizontal plane;

[0063] (2) Clamping the aeroengine blade on the fixture 8;

[0064] (3) Roughly measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com