Sensor setting method for supporting failure prediction

A sensor and sensor quantity technology, applied in the direction of instruments, analysis materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described now in conjunction with accompanying drawing:

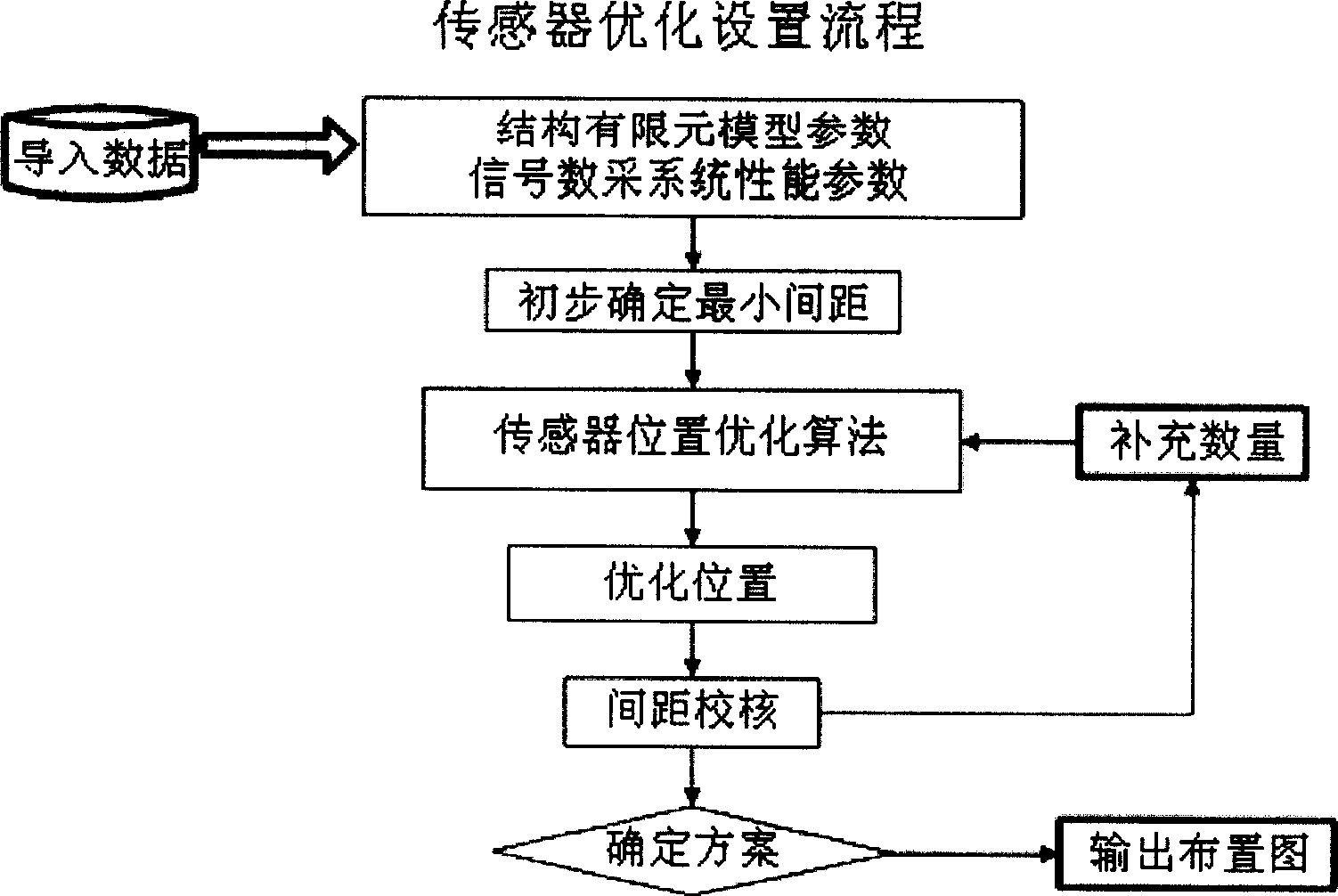

[0035] Sensor Quantity Optimization Method

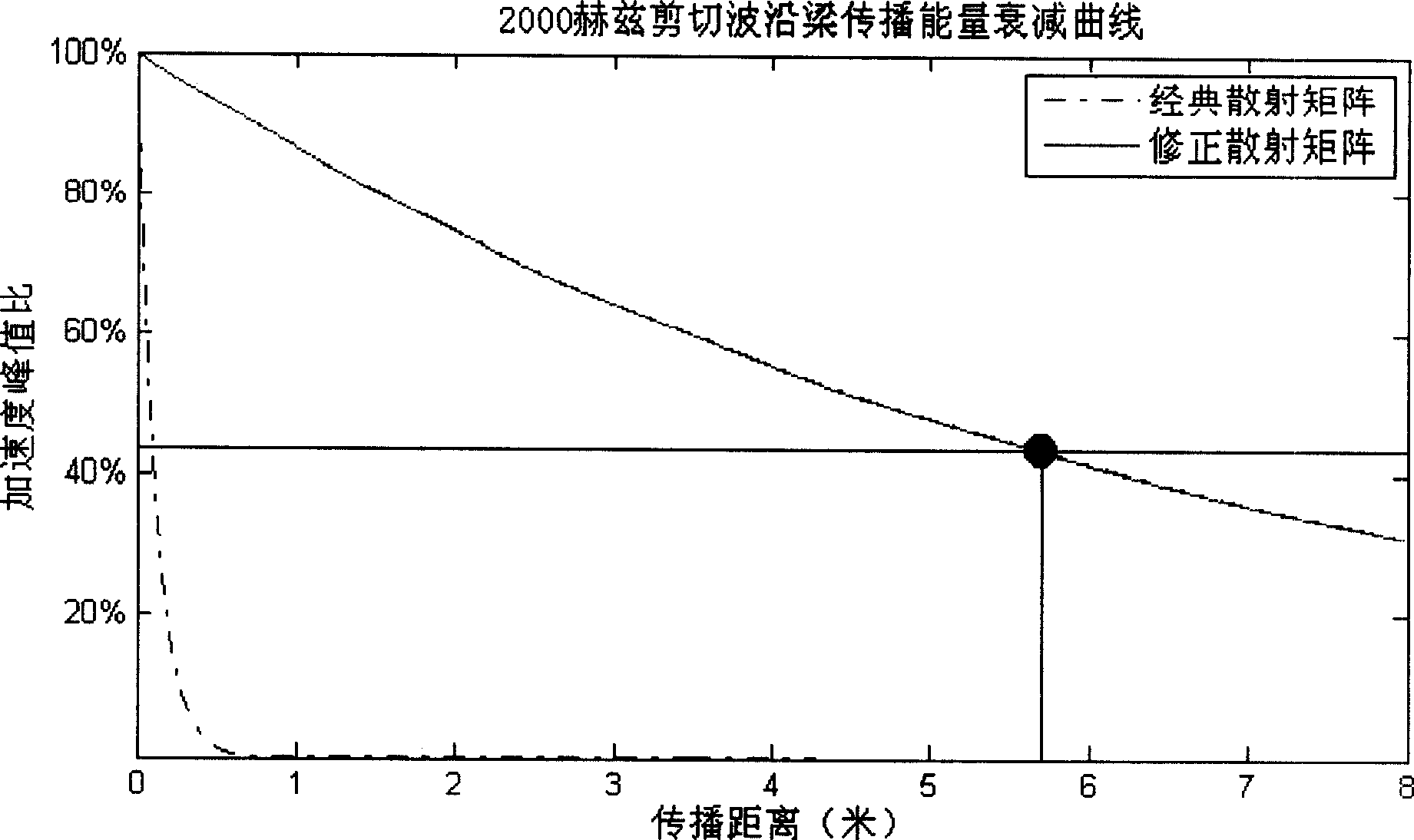

[0036] Suppose the measuring range of the instrument is A and the precision is η, then the absolute error limit is A×η. The formula for calculating the peak signal-to-noise ratio threshold P is: P = 10 log 10 ( a Sig 2 / a Noi 2 ) , In practical application, P can be obtained from instrument precision statistics.

[0037] Obtain the minimum acceleration peak value of the signal:|a min |≥A×η×10 0.05P

[0038] According to the modified Timoshenko beam theory, the lateral motion of the beam can be expressed as

[0039] κAG ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com