Method for implementing matching test for automatic test equipment

A technology of automatic test equipment and matching test, which is applied in the direction of digital circuit test, electronic circuit test, and electrical measurement. It can solve the problems of cumbersome, chip test constraints, and no matching test function, etc., and achieve the effect of expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

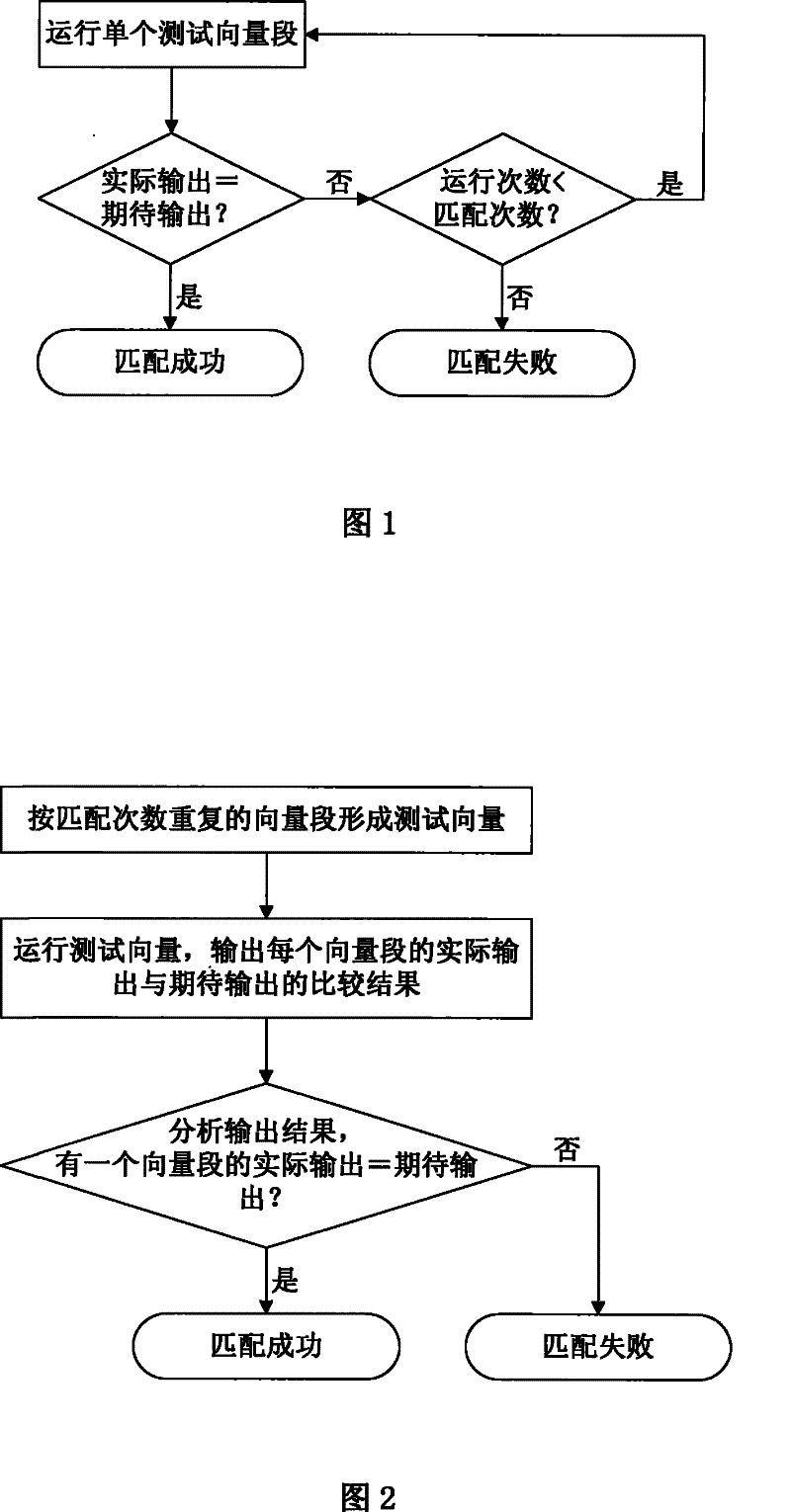

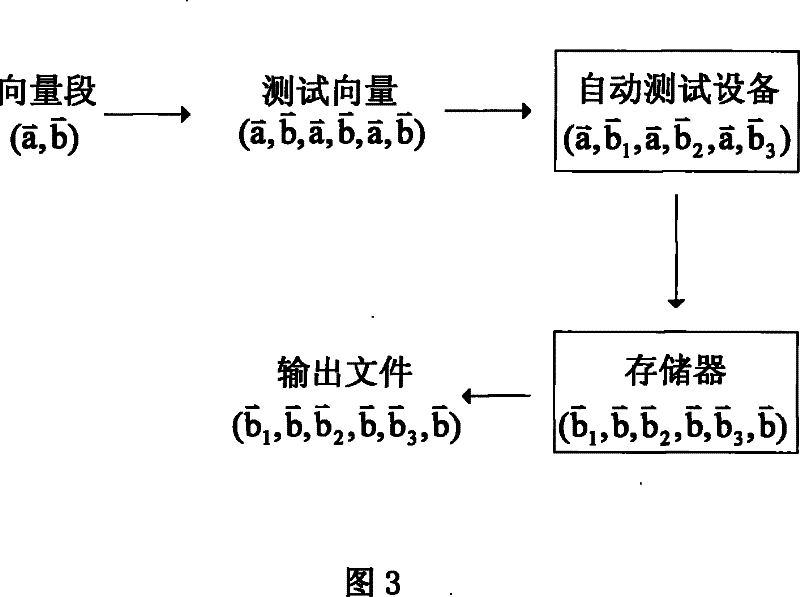

[0017] see figure 2 , the automatic test equipment of the present invention realizes the method for matching test and comprises the following steps:

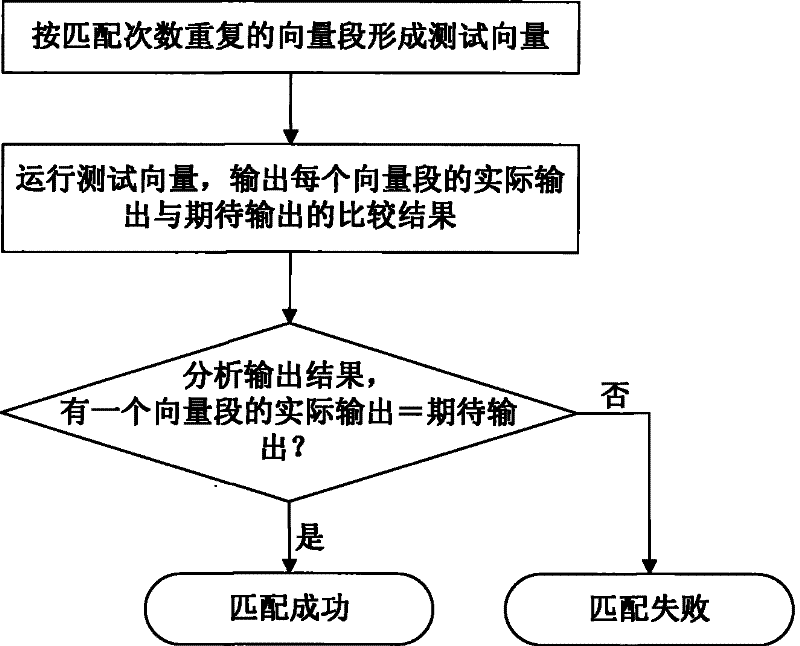

[0018] In the first step, a test vector is formed, the test vector includes a plurality of repeated vector segments, and each vector segment includes an input of the circuit to be tested and a corresponding expected output. The traditional matching test is to repeatedly test a vector segment, and the test vector constructed in this step of the present invention is formed by repeating a vector segment many times.

[0019] In the second step, the test vector is run on the circuit to be tested by the automatic test equipment, the actual output of each vector segment is compared with the expected output, and the comparison result is output as a file. The traditional matching test needs to be supported by the automatic test equipment. For the automatic test equipment that does not support the matching test, running the test vector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com