Optical module

A technology of optical modules and optical fibers, applied in the field of optical modules, can solve problems such as difficulty in ensuring yield rate and difficulty in yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

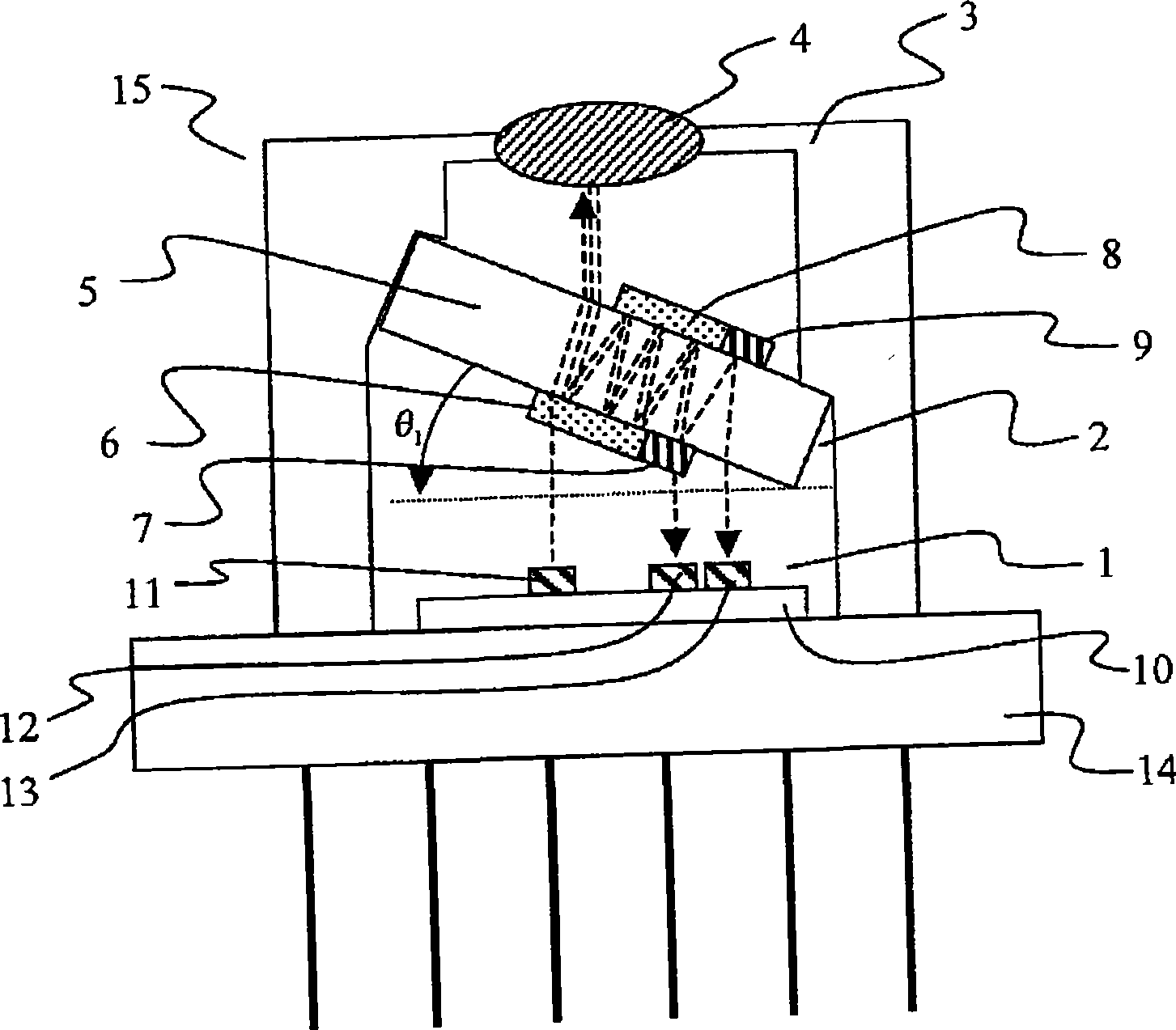

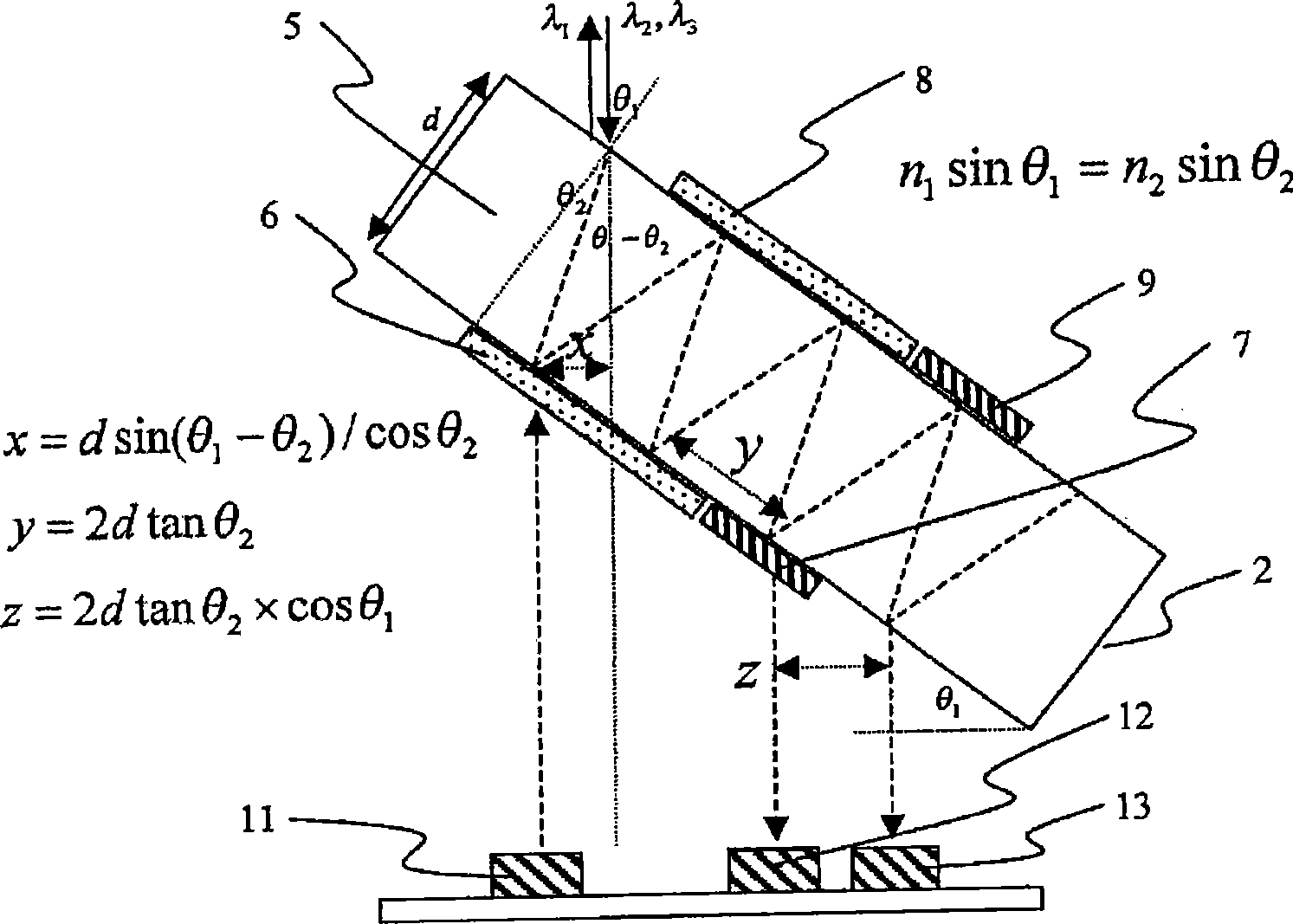

[0049] figure 1 is a cross-sectional view of an optical module as a first embodiment of the present invention. figure 1 This is an example in which the present invention is applied to a module called an optical triplexer using a three-wavelength bidirectional optical transmission and reception module.

[0050] figure 1 It is an example of mounting on a CAN package. The light-emitting element 11 and light-receiving elements 12, 13 are loaded on the base 10. The optical element loading substrate 1 is installed on the CAN socket 14, and the optical multiplexer and demultiplexer 2 is installed on the On the CAN cover 3, a triplexer module 15 is formed. The operating wavelengths of the optical elements 11, 12, and 13 are λ1, λ2, and λ3 respectively, and the length relationship of the wavelengths is λ1 figure 1 In the upper part, the elements are arranged from elements with shorter wavelengths to elements with longer wavelengths. Concave-convex for installing optical multiplex...

Embodiment 2

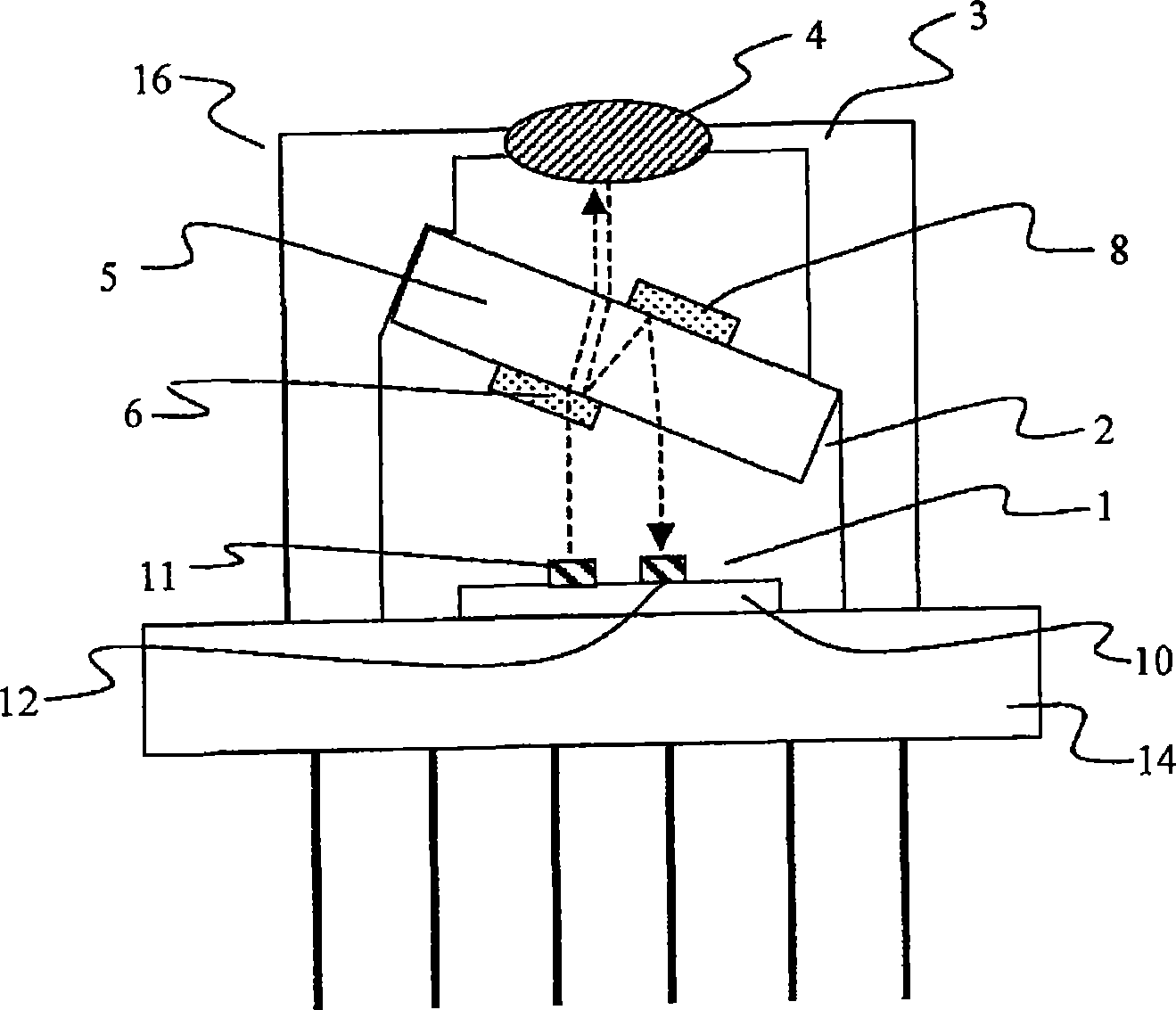

[0057] image 3 is a cross-sectional view of an optical module according to a second embodiment of the present invention. This embodiment is a configuration example in which the present invention is applied to a two-wavelength single-core bidirectional (BIDI: Bi-Directional) module. Such as image 3 As shown, the BIDI module 16 is the same as the first embodiment in that it is composed of the optical element mounting substrate 1 , the wavelength multiplexer / demultiplexer 2 and the CAN package 3 . However, since the BIDI module transmits and receives at two wavelengths, one upstream wavelength and one downstream wavelength, the only optical elements mounted on the optical element mounting substrate 1 are the light emitting element 11 and the light receiving element 12 . On the optical multiplexer / demultiplexer 2, one type of optical filter 6 and mirror 8 are respectively installed.

Embodiment 3

[0059] Figure 4 is a cross-sectional view of an optical module according to a third embodiment of the present invention. This embodiment is an example in which the present invention is applied to a so-called pigtail type module with optical fibers. Such as Figure 4 As shown, the triplexer module 15 of the first embodiment of the present invention is installed on the coaxial square module housing 21 , and an optical fiber 22 with a ferrule is further installed through a sleeve (sleeve) 23 . In this example, an example of a pigtail type module is shown, but a removable type (resectable) module can also be configured with the same structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com