Heat radiating fin and heat radiator

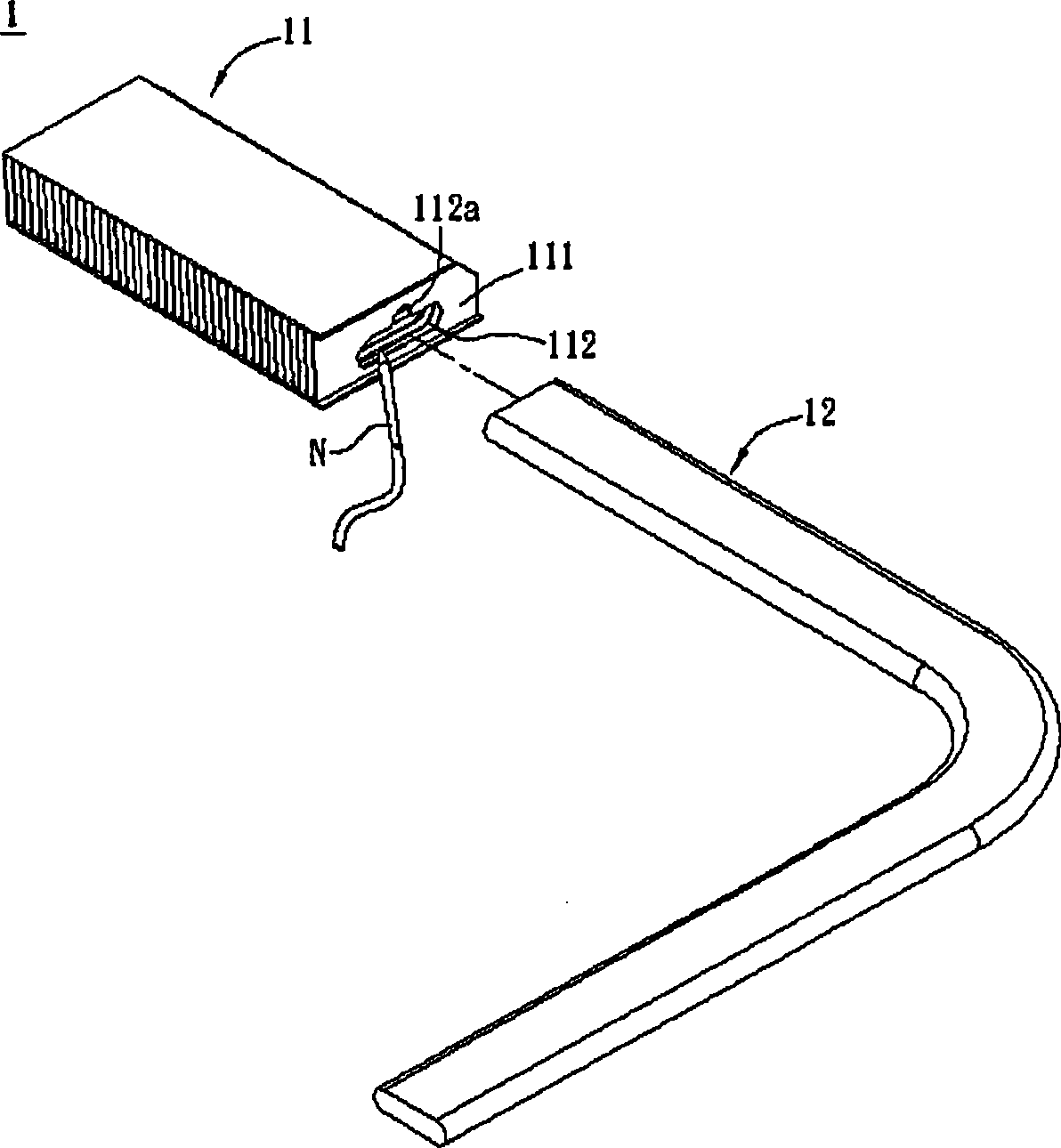

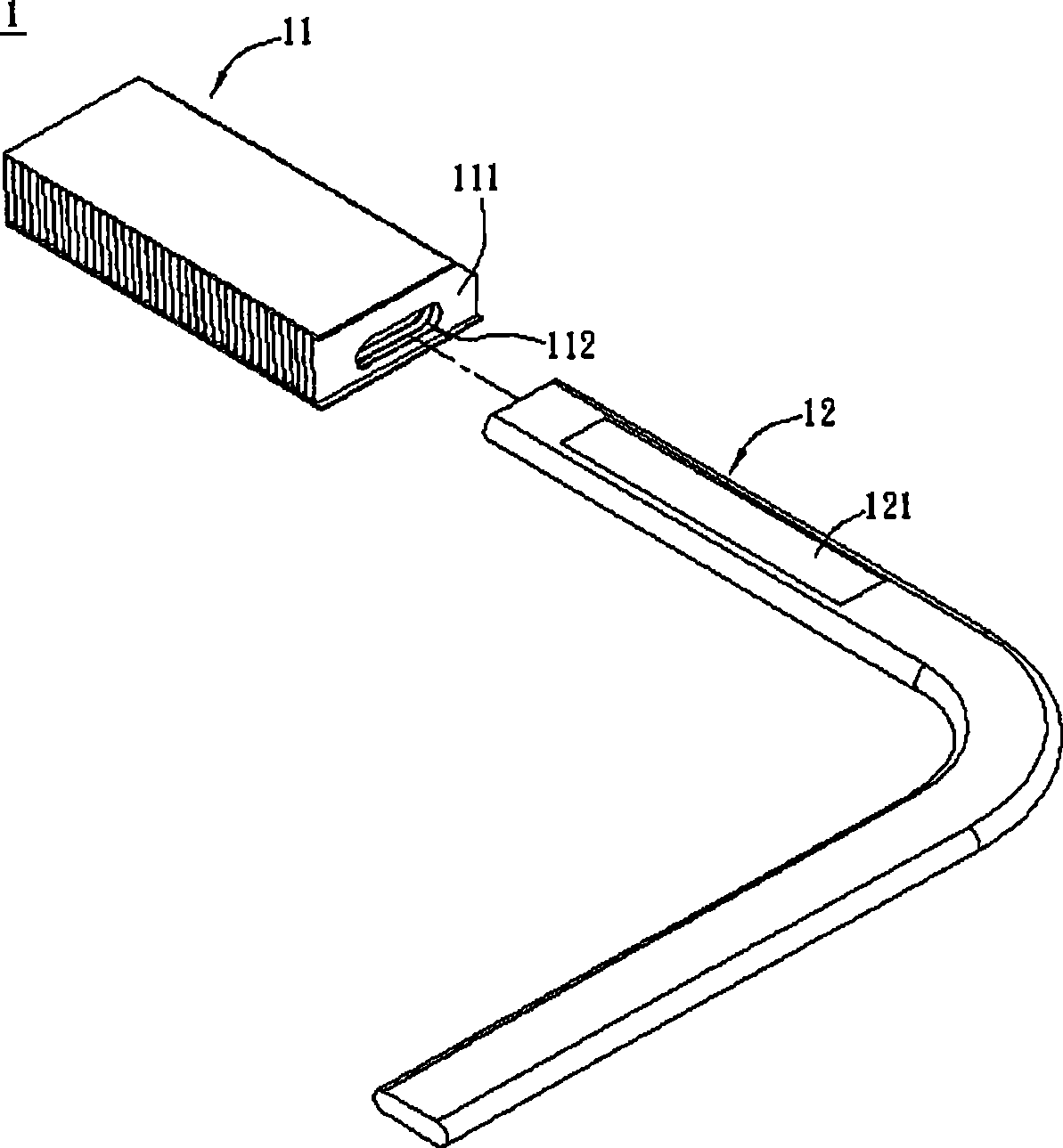

A heat sink and heat sink technology, which is applied in the direction of electric solid devices, semiconductor devices, cooling/ventilation/heating transformation, etc., can solve the problem that the combination of heat pipe 12 and heat sink group 11 is reduced, and the other end of the accommodating hole 112 Problems such as overflow, uneven thickness of solder paste, etc., to save costs, speed up the time of setting solder paste, and improve the uniformity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, a heat sink and a heat sink according to a preferred embodiment of the present invention will be described with reference to the related drawings, wherein the same components will be described with the same reference signs.

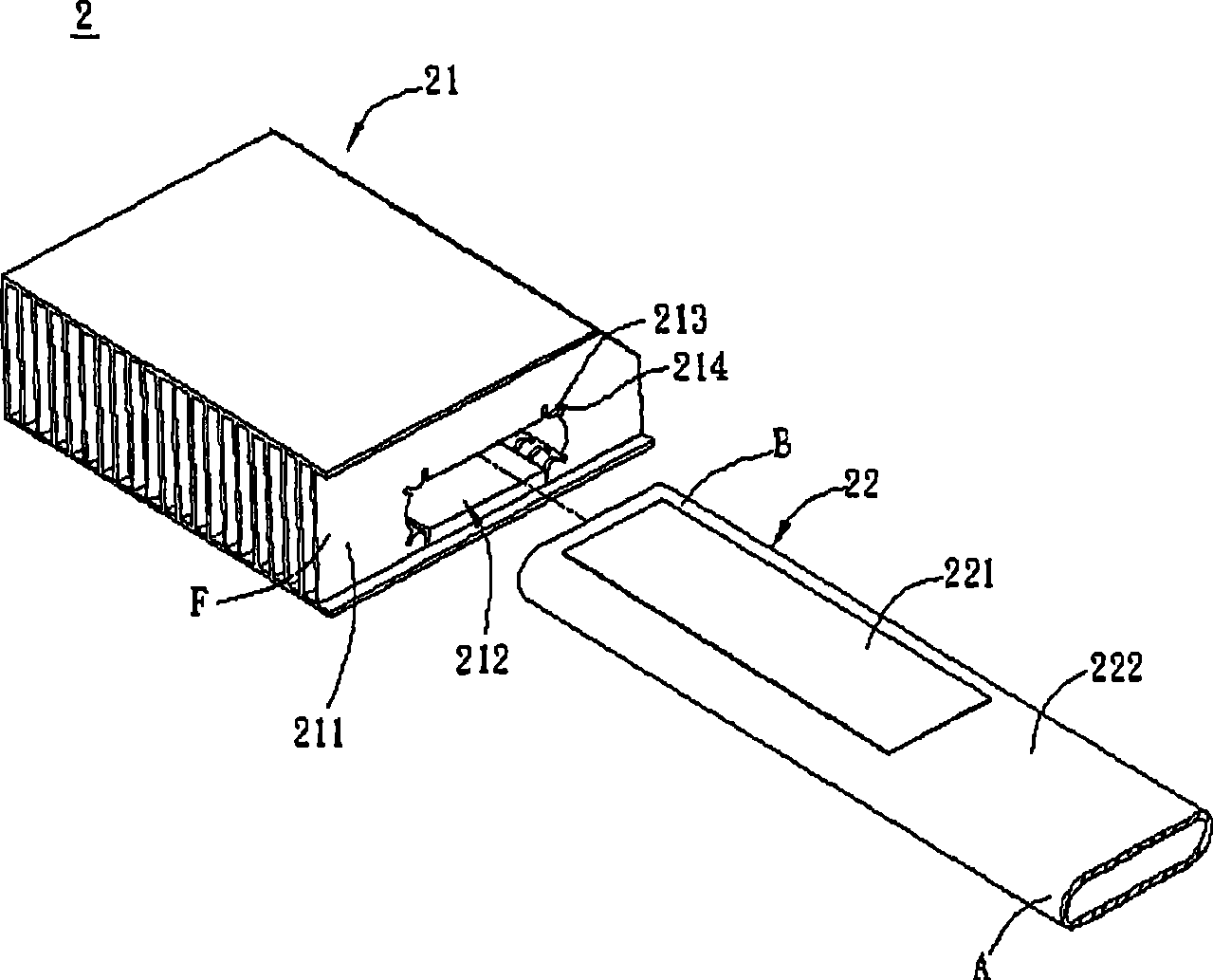

[0015] figure 2 Shown is a heat sink 2 according to a preferred embodiment of the present invention. The heat sink 2 includes a heat sink group 21 and a heat pipe 22 . image 3 Shown is a schematic cross-sectional view of the heat sink 211 with the heat pipe 22 passing through the accommodating hole 212 . Please refer to figure 2 and image 3 Explain radiator 2.

[0016] The heat sink set 21 has a plurality of heat sinks 211 connected to each other. Each heat sink 211 has a heat sink body F and a plurality of positioning protrusions 213. The heat sink body F has an accommodating hole 212 for the heat pipe 22 to pass through. The accommodating holes 212 of the heat sinks 211 are aligned with each other, and the positioning protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com