Device and method for the production of plastic containers

A technology for plastic containers and production equipment, applied in plastic container production equipment and fields, can solve the problems of inflexibility, increased cost and complexity, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

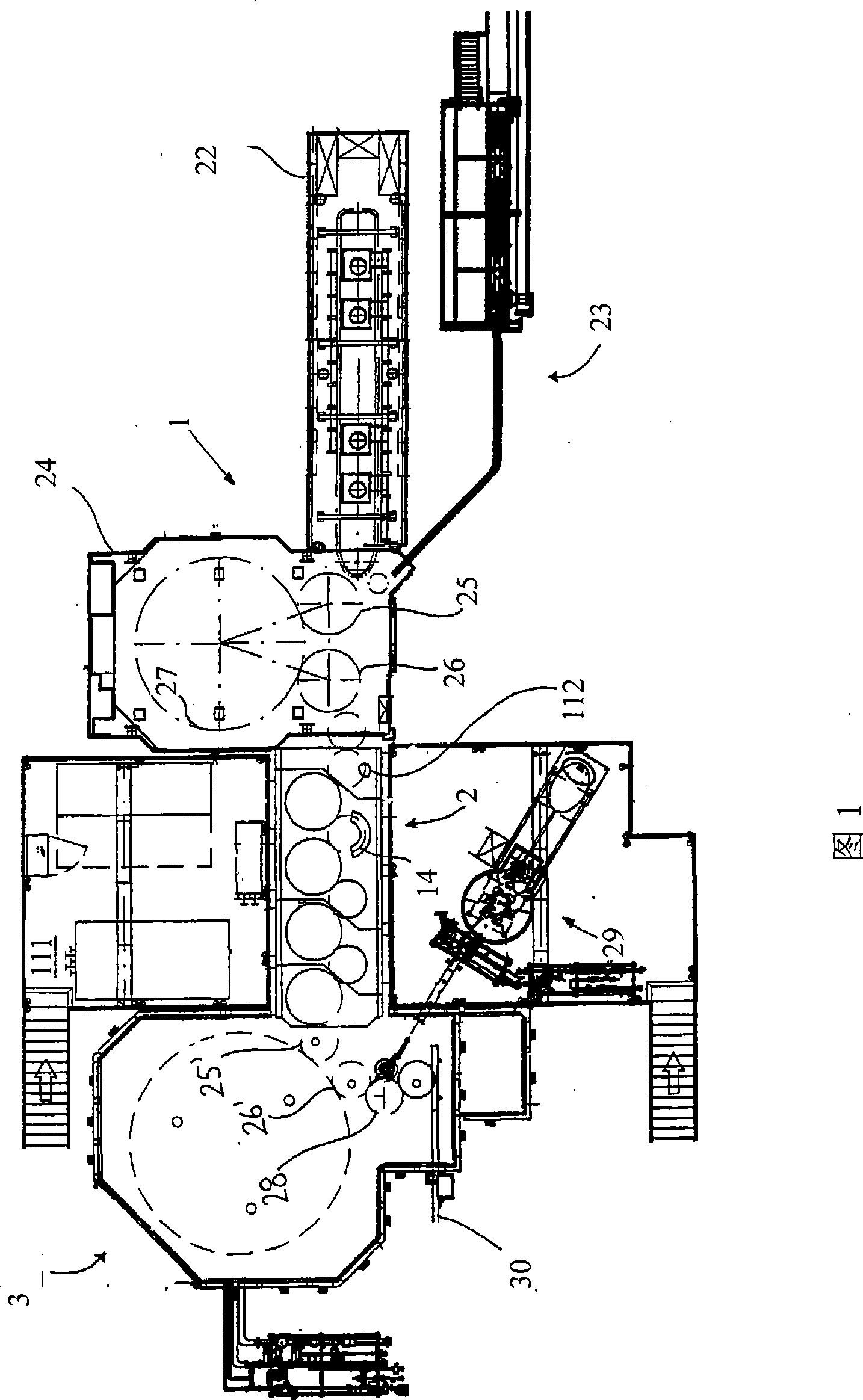

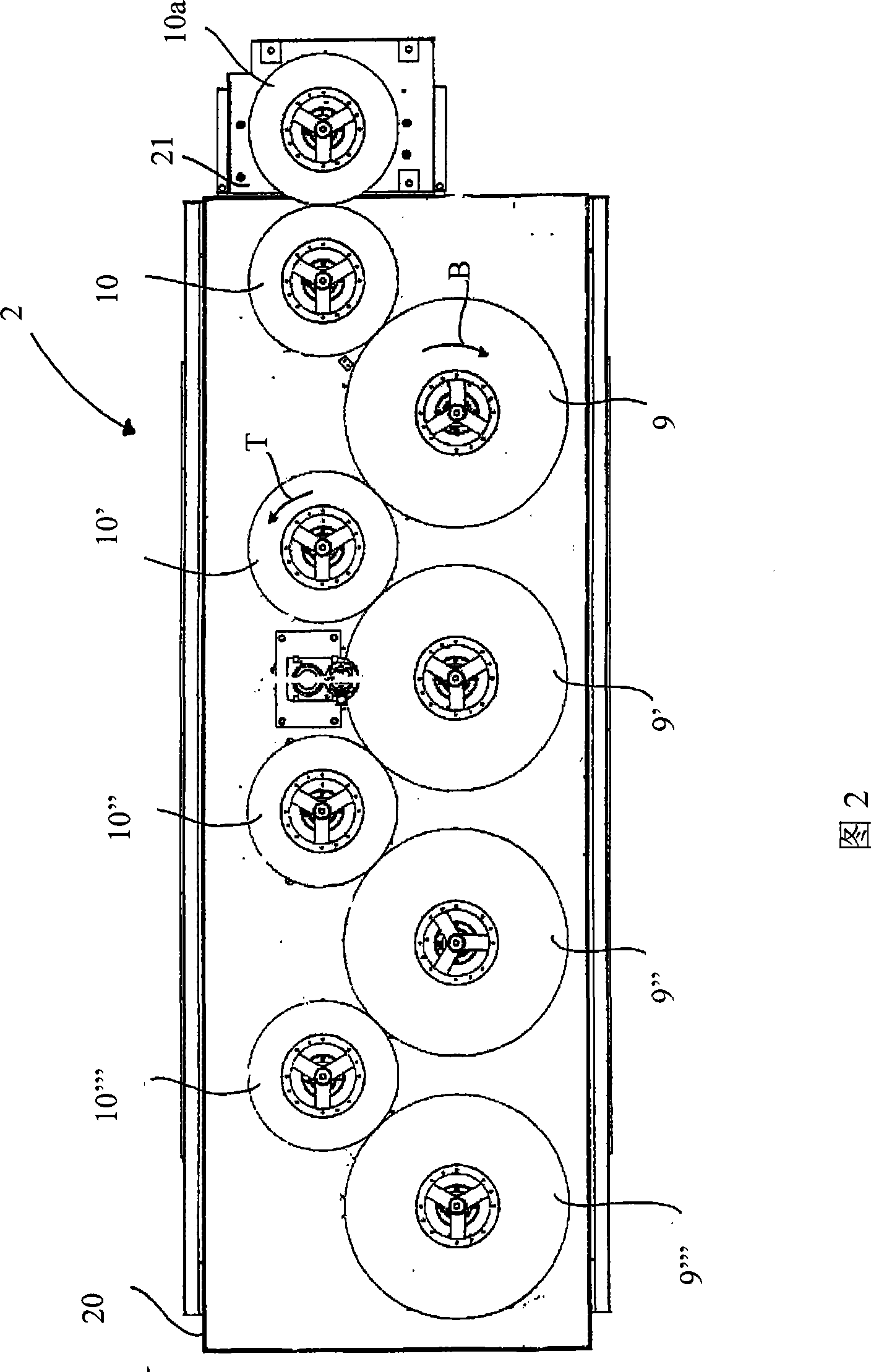

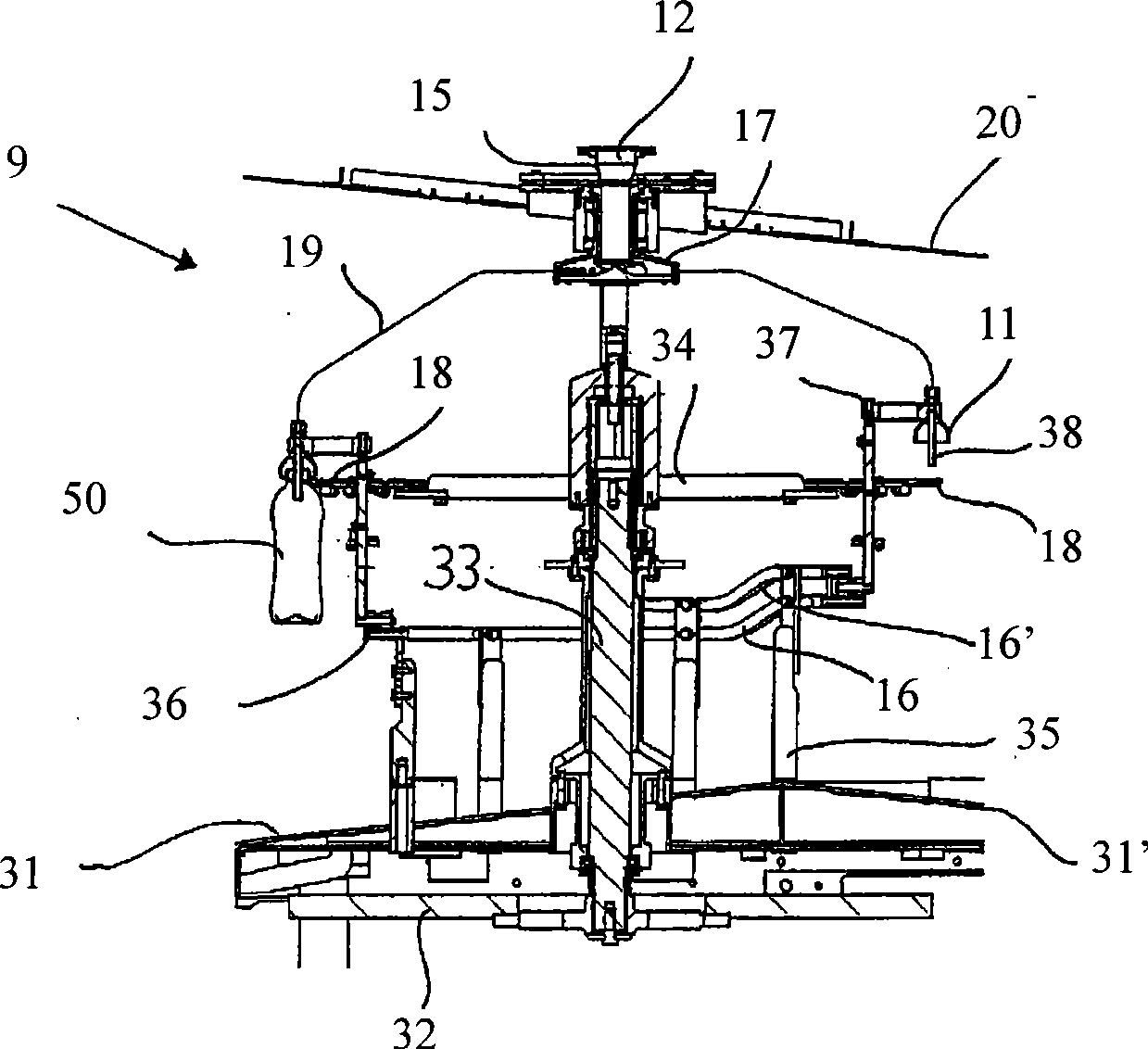

[0027]FIG. 1 shows a container production plant 1 comprising a preform sorting and feeding device 23 , a heating furnace 22 and a stretch blow molding machine 24 . The preforms are fed from a storage device (not shown) into a preform sorting device 23 and conveyed through a supply system to a heating furnace 22 where they are heated to a certain temperature. The heating furnace 22 may be an infrared heating furnace or a microwave oven. After exiting the furnace 22 the heated preforms are transferred via the inlet star wheel 25 to the blowing wheel 27 . The blow molding wheel is provided with a plurality of blow molds (not shown in the figure), and the preform is blown by compressed air in these blow molds. The blow-molded bottles are then picked up by the outlet starwheel 26 and transferred to the transfer starwheel 10a, which serves as the outlet starwheel 26 and the first transfer starwheel in the container processing station 2 10 transmission connection devices between. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com