Liquid level measurement device

A technology of liquid level and measuring tube, applied in the direction of measuring device, liquid/fluid solid measurement, liquid level indicator for physical variable measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

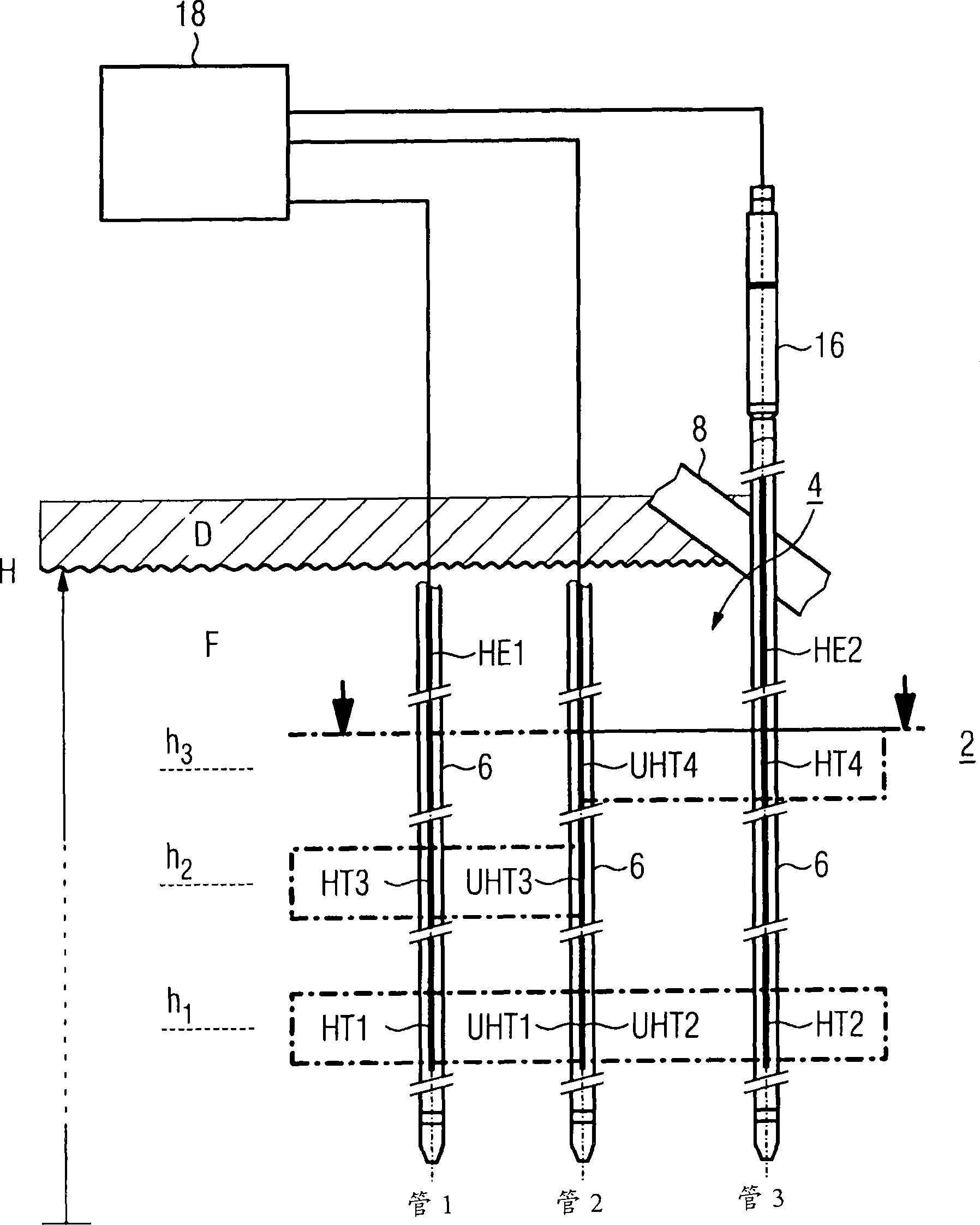

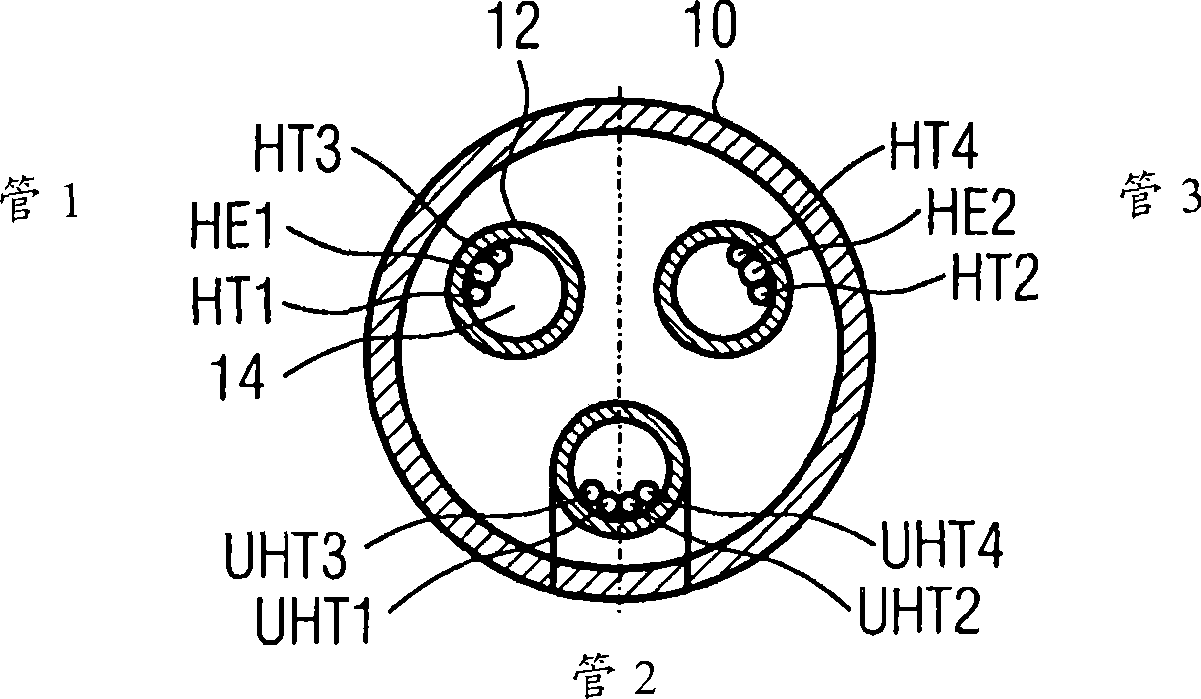

[0025] one in figure 1 shown in partial side sectional view and in figure 2 The device 2 for level measurement shown in sectional view in the figure serves to monitor the level of a cooling fluid F in a reactor pressure vessel 4 of a pressurized water reactor (not shown in detail). The device 2 comprises three long measuring tubes 6 each designed in the form of an instrument tube, which are inserted into the interior of the reactor pressure vessel 4 from above through openings in the cover plate 8 designed for it when the measuring device 2 is assembled. , and is at least partially immersed in the cooling fluid F during the operation of the nuclear reactor. The height of the liquid level or the height of the liquid level is above the bottom surface of the container at figure 1 Indicated by H, where of course other reference levels can be applied. A vaporous cooling medium, referred to as vapor D, is located above the liquid level.

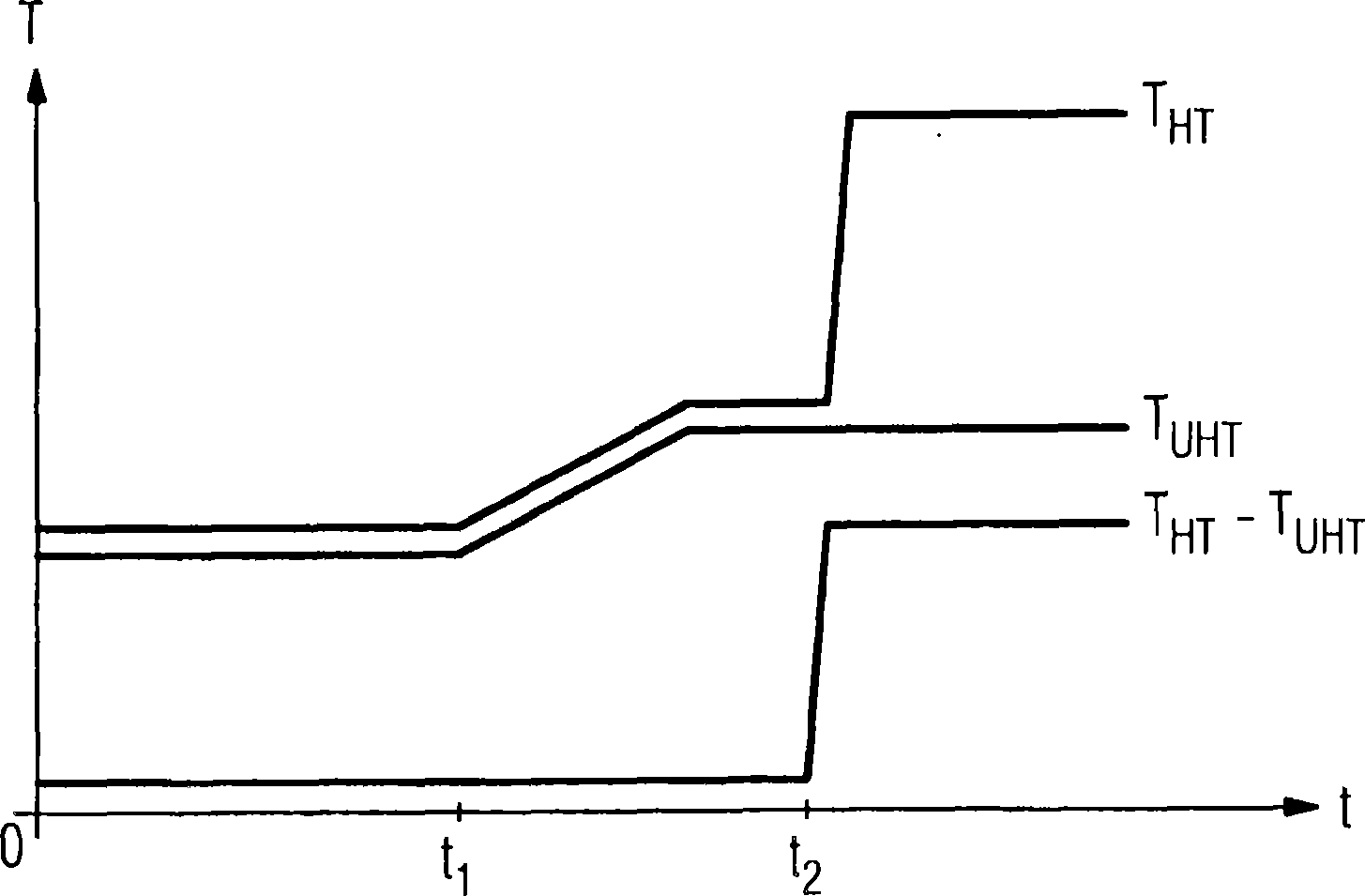

[0026] The three measuring tubes 6 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com