Automatic irrigation system

An automatic irrigation system and solenoid valve technology, applied in horticulture, botany equipment and methods, cultivation, etc., can solve the problems of increasing the cost of use, low precision of instruments, and affecting plant growth, so as to increase the application possibility and reduce the The effect of manual operation and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

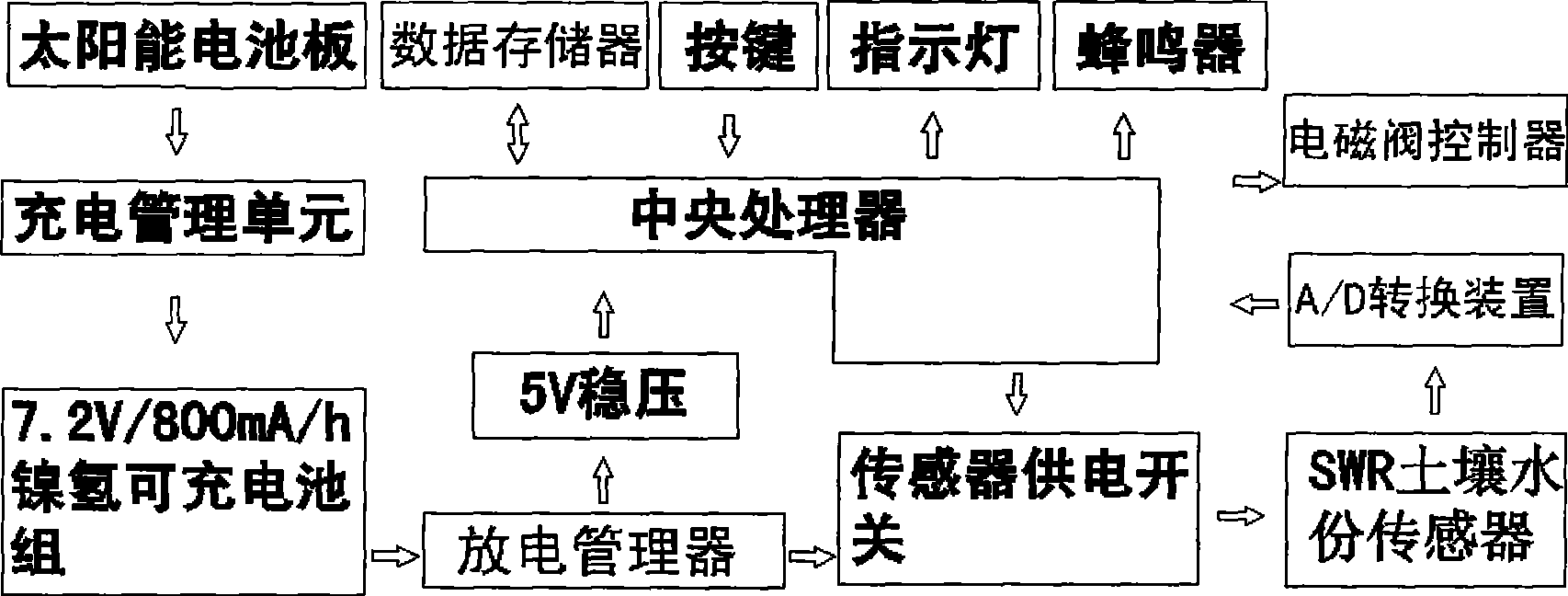

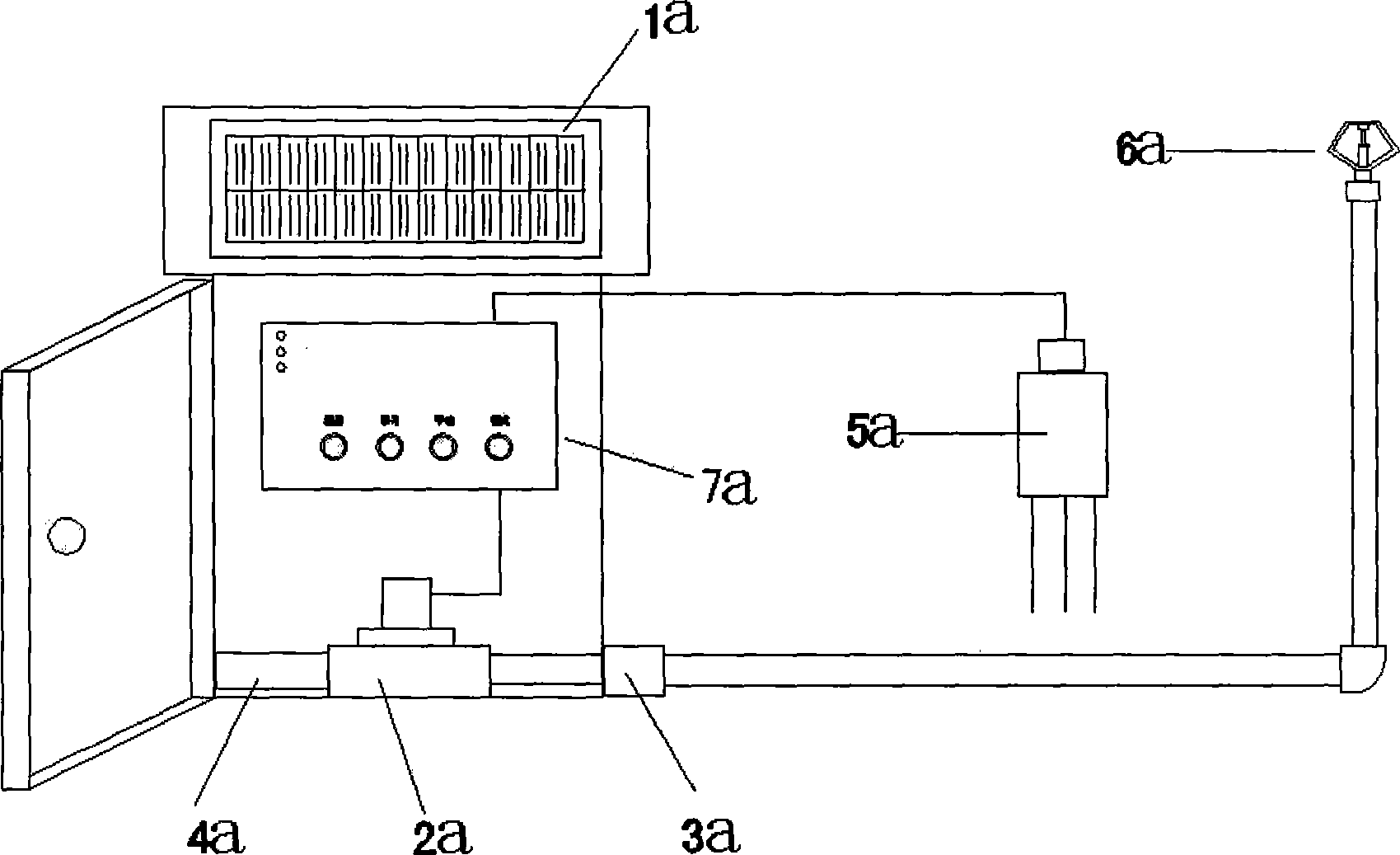

[0035] figure 1 The principle of the wired automatic irrigation system of the present invention is given. The system is mainly composed of a main control device, a solenoid valve, and a sensor device. , indicator light and buzzer. The solenoid valve in this system uses a self-holding solenoid valve, which is controlled by the central processing unit in the main control device. The conversion device and the sensor power supply switch are connected to the central processing unit. The power supply device in the device is composed of a solar panel, a charge manager, a Ni-MH rechargeable battery pack and a discharge manager connected in sequence, and the discharge manager is respectively connected to the central processing unit and the sensor power supply switch. The above-mentioned data memory connected with the central processing unit is adopted as EEPROM.

[0036] When the system is running, the power supply of the whole device is powered by a 7.2V / 800mA / h Ni-MH rechargeable ...

specific Embodiment 2

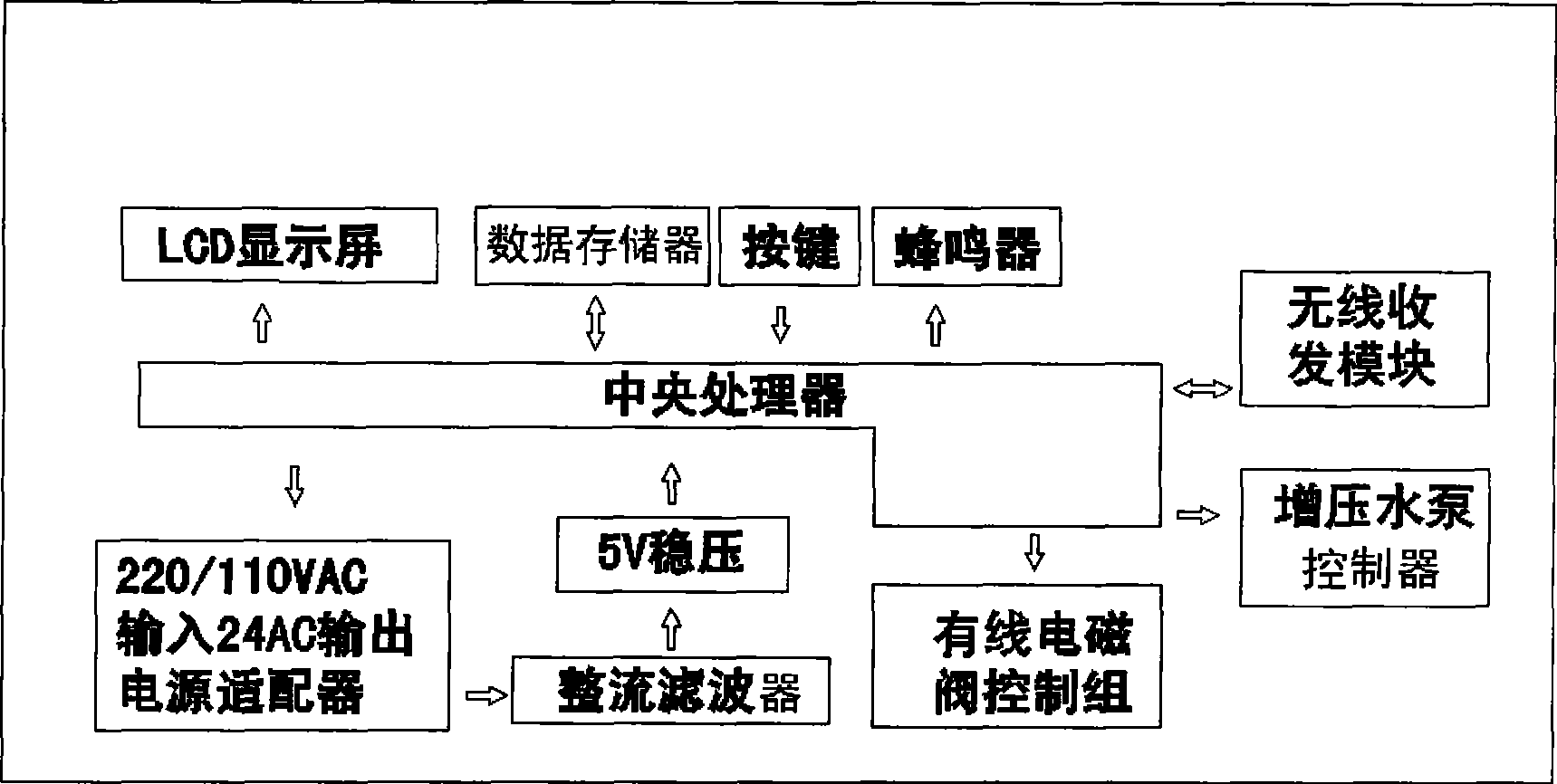

[0039] In this example, the Figure 3 to Figure 5 The principle shown, image 3 The principle structure of the group control device in this system is given. Its internal central processing unit is respectively connected to the LCD display, data memory, buttons, buzzer, power adapter and rectifier filter in the power module. At the same time, the central processing unit The transmitter is also connected with a wireless transceiver, a wired solenoid valve control group and a booster water pump control device.

[0040] Figure 4 The principle block diagram of the wireless solenoid valve device is given, which includes the central processing unit and the power supply unit connected to it, data memory EEPROM, indicator light, wireless transceiver and solenoid valve. The solenoid valve is a pulse-triggered self-holding solenoid valve. At the same time, the solar battery panel, the charge manager, the rechargeable battery pack and the discharge manager in the power supply device a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com