Aluminum foil bundling/splitting machine vertically passing method in aluminum foil workshop

A technology of slitting machine and internal coiling, which is applied to other manufacturing equipment/tools, metal rolling, manufacturing tools, etc. It can solve the problems of damaging aluminum foil, affecting the yield of aluminum foil, and the pressure on the outer surface of aluminum coils, etc., and achieves improvement. Yield rate, reduction of infrastructure investment and production and operation costs, and the effect of compact overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

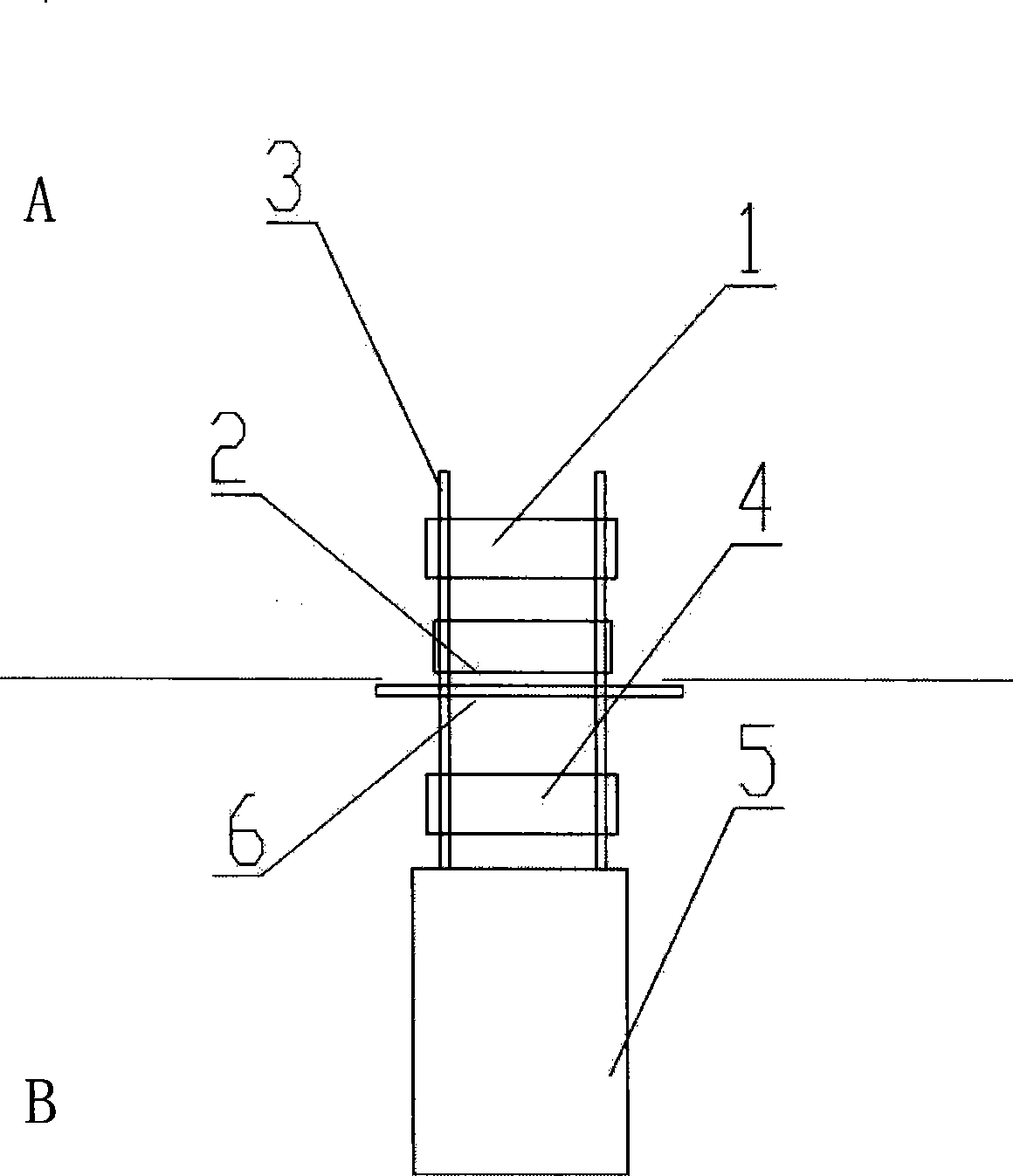

[0019] Such as figure 1 Shown: A method for vertically spanning the coil / slitting machine in the aluminum foil workshop is to place the aluminum foil coiling / slitting machine perpendicular to the aluminum foil rolling span A and slitting span B in the aluminum foil workshop, and place the equipment The entrance loading frame 1 is placed in the rolling span A, and a transmission and transportation device 2 is provided on the floor between the entrance loading frame 1 of the equipment coiling / slitting machine and the uncoiler 4, which is connected by a track 3; The span is that the transmission track 3 of the transmission transport device 2 is substantially flat with the floor, forming a span between the two spans.

[0020] The uncoiler and the aluminum foil splitting / slitting and winding host part are placed in the adjacent slitting span B, so that the equipment forms a cross-span configuration between the two spans. There is a wall between the rolling span A and the cutting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com