Screw rod injection type plant fibre steam blasting device and method

A plant fiber and injection type technology, which is applied in the field of screw injection type plant fiber steam explosion device, can solve the problems of plant fiber performance damage, low fiber quality, increased equipment investment cost, etc., and achieves the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

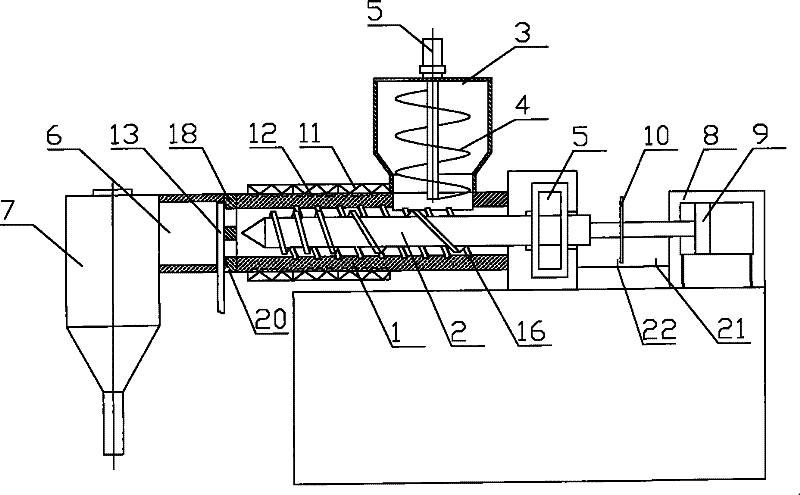

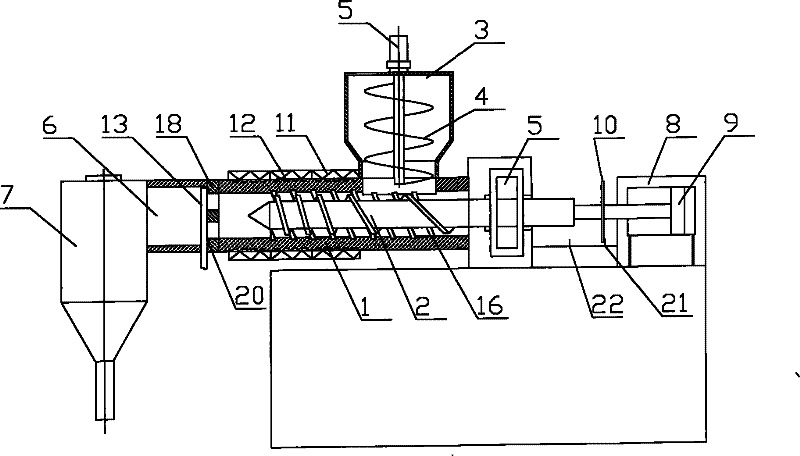

[0035] like Figure 1 to Figure 4 As shown, a screw injection type plant fiber steam explosion device includes a barrel 1, an extrusion screw 2 matched with it is arranged in the barrel 1, a feeding port and a discharging port are arranged on the barrel 1, A quick-opening valve 13 is provided at the discharge port, the extruding screw 2 is driven by a driving mechanism (such as a motor 5), a propulsion mechanism is provided at the rear end of the extruding screw 2, and a temperature controller is provided on the barrel 1.

[0036] A feeding hopper 3 is provided at the feeding port, and a feeding screw 4 is provided in the feeding hopper 3, and the feeding screw 4 is driven by a driving mechanism (such as a motor 5).

[0037]The steam explosion device also includes a transition sleeve 6 and a cyclone separator 7 , the transition sleeve 6 is arranged at the rear end of the quick-opening valve 13 , the cyclone separator 7 is arranged at the rear end of the transition sleeve 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com