Method for preparing lignin phenolic monomers by depolymerizing lignin

A technology of lignin phenol and lignin, which is applied in ether preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as harsh reaction conditions, lower reaction temperature and pressure, and low efficiency, and achieve product selectivity High efficiency, simple operation process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

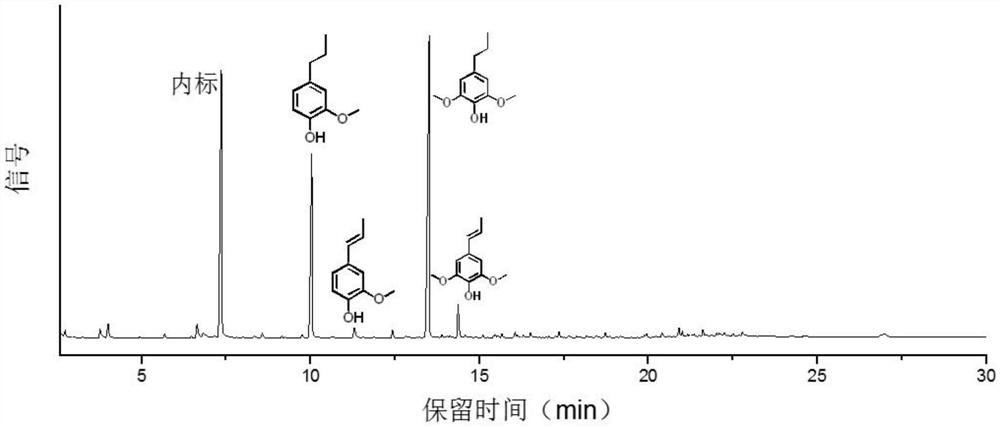

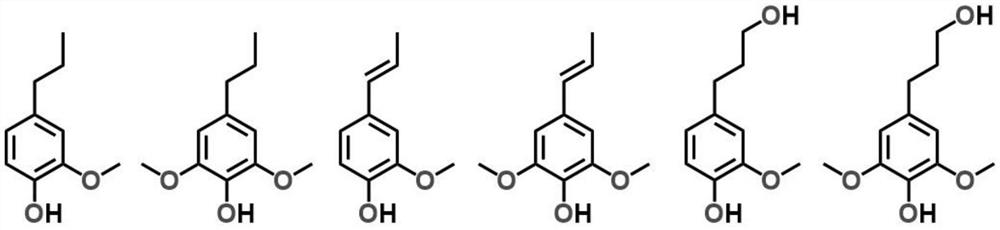

[0023] A method for preparing lignin phenolic monomers by depolymerizing lignin, comprising the following steps: placing 1 g of poplar sawdust and 0.2 g of Ru / C catalyst in 20 ml of ethylene glycol, adding sulfuric acid, and finalizing the sulfuric acid in the ethylene glycol. The concentration is 0.5g / L; under the gauge pressure of 300kPa and 220°C, the reaction is carried out for 0.5h to obtain lignin phenolic monomers.

[0024] The supported mass of Ru in the Ru / C catalyst used in this example was 5%.

[0025] The total yield of propyl guaiacol, propyl eugenol, propyl guaiacol and propyl eugenol was 19.7 wt%, and the selectivity of propyl guaiacol and propyl eugenol was 72.1 wt%.

Embodiment 2

[0027] A method for preparing lignin phenolic monomers by depolymerizing lignin, comprising the following steps: placing 1 g of eucalyptus wood chips and 0.02 g of Ru / C catalyst in 50 ml of ethylene glycol, adding sulfuric acid, and finalizing the sulfuric acid in the ethylene glycol. The concentration is 0.1 g / L; under the gauge pressure of 150 kPa and 200 ° C, the reaction is carried out for 2 h to obtain lignin phenolic monomers.

[0028] The supported mass of Ru in the Ru / C catalyst used in this example was 15%. The total yield of propyl guaiacol, propyl eugenol, propyl guaiacol and propyl eugenol was 22.4 wt%, and the selectivity of propyl guaiacol and propyl eugenol was 88.2 wt%.

Embodiment 3

[0030] A method for preparing lignin phenolic monomers by depolymerizing lignin, comprising the following steps: placing 1 g of willow sawdust and 0.5 g of Ru / C catalyst in 10 ml of ethylene glycol, adding phosphoric acid, and the final concentration of phosphoric acid in the ethylene glycol is 4.0 g / L; under the gauge pressure of 0 kPa and 185 ° C, the reaction is carried out for 6 h to obtain lignin phenolic monomers.

[0031] The supported mass of Ru in the Ru / C catalyst used in this example was 0.5%. The total yield of propyl guaiacol, propyl eugenol, propyl guaiacol and propyl eugenol was 21.8 wt%, and the selectivity of propyl guaiacol and propyl eugenol was 95.1 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com