A treatment method for oil-containing waste catalyst discharged from ebullated bed

A waste catalyst and treatment method technology, applied in the petroleum industry, refined hydrocarbon oil, solid waste removal, etc., can solve the problem that there is no good treatment method for the oily waste catalyst discharged from the fluidized bed, increasing the complexity of the device and operating costs, and equipment Large footprint and other issues, to achieve the effect of harmless treatment, efficient dissolution and separation, and improvement of raw material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

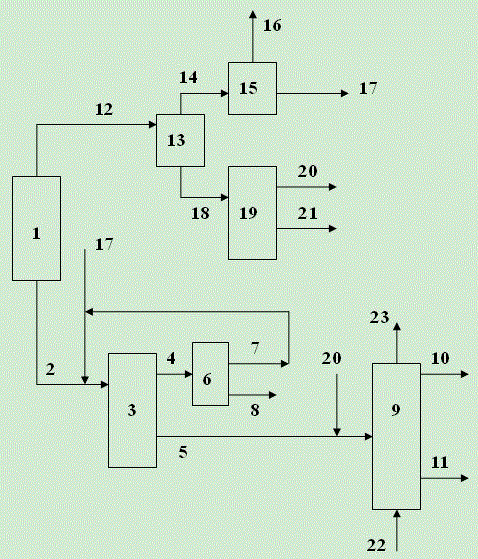

Method used

Image

Examples

Embodiment 1

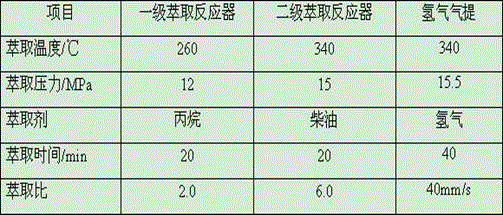

[0029] The process of producing light oil by using the ebullated bed process with residual oil as raw material, the properties of the raw material are shown in Table 1, the conditions of the ebullated bed hydrogenation process are shown in Table 2, and the catalyst is [give the serial number or specific properties of the product]

[0030]Table 1 General properties of the raw oil used in the test

[0031]

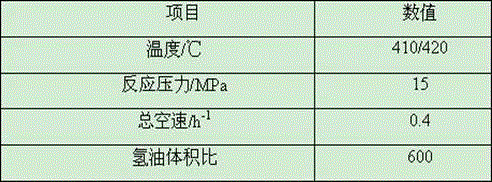

[0032] Table 2 Fluidized bed hydrogenation process conditions

[0033]

[0034] As the reaction proceeds, when the catalyst activity cannot meet the reaction requirements and a part of the catalyst needs to be unloaded, the oil-containing waste catalyst is discharged through the reactor discharge port. The properties of the oil-containing waste catalyst are shown in Table 3, and the oil-containing waste catalyst enters the first stage The extraction reactor and the secondary extraction reactor carry out the extraction reaction, wherein, the operating conditions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com