Fast cooling method for high-power LED lamp

A high-power and fast technology, used in lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc., can solve problems such as inability to dissipate heat, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

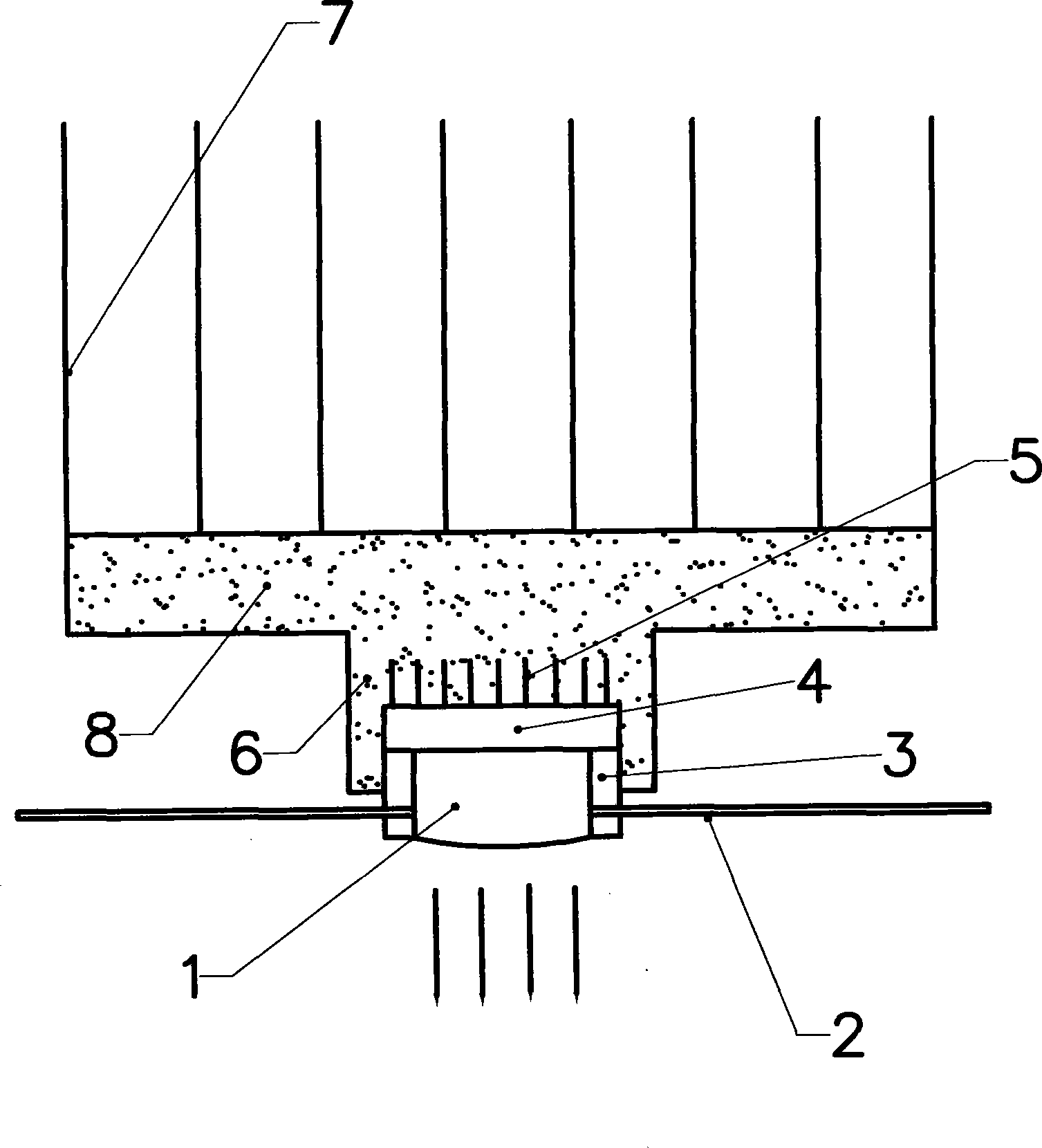

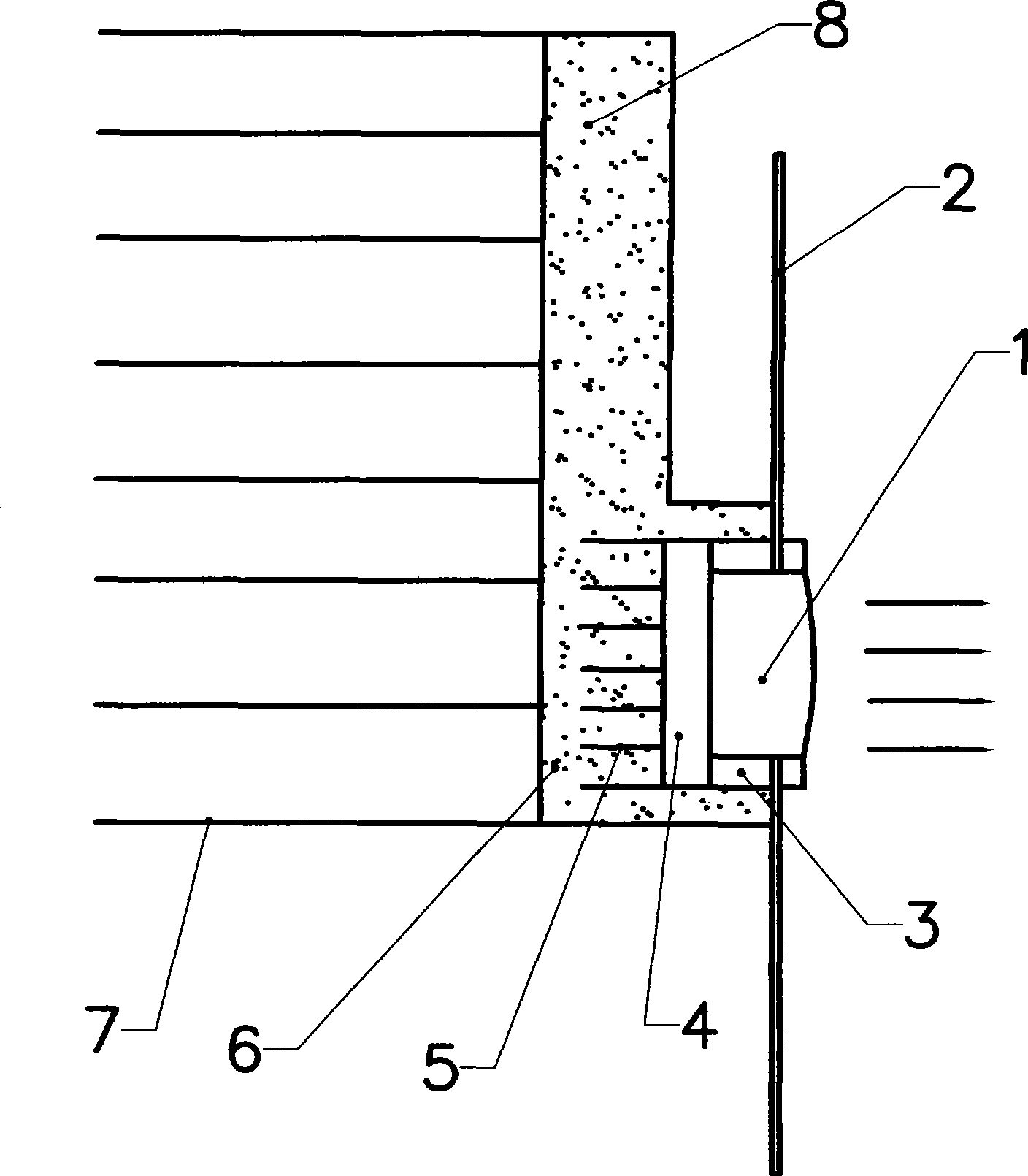

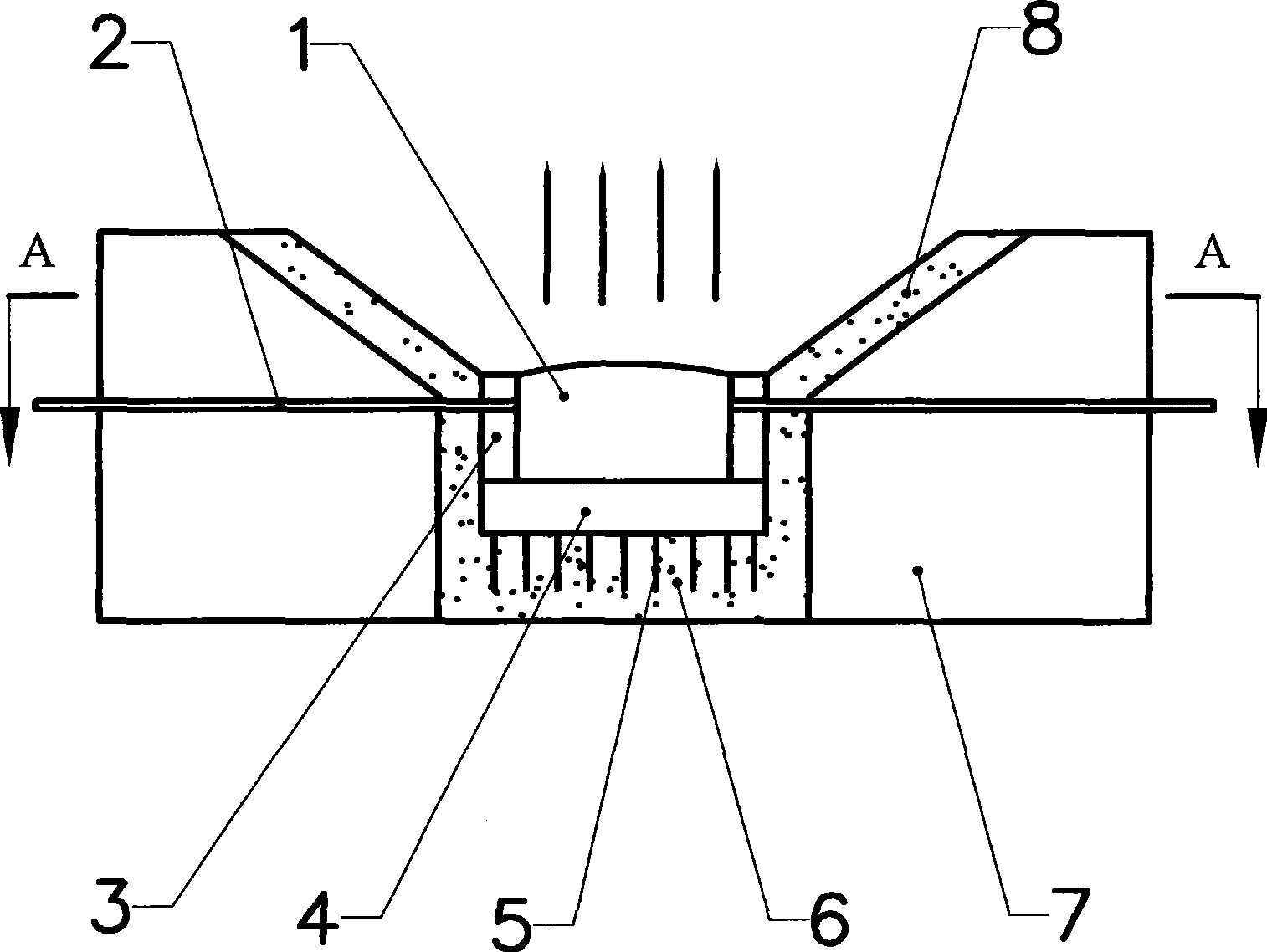

[0027] figure 1 It is a structural schematic diagram of an embodiment of the present invention using a single chip illuminated under light.

[0028] figure 1 Among them, inner heat dissipation blades (5) are arranged at the bottom of the heat dissipation metal base (4) to increase the heat dissipation area, so that the heat generated by the LED chip (1) is transferred to the inner heat dissipation blades (5) through the heat dissipation metal base (4) , can accelerate the dissipation of heat; the liquid storage chamber (6) surrounds the heat dissipation metal base (4) and the inner heat dissipation blade (5) and leaves a certain space, and the heat dissipation distribution chamber (8) communicates with the liquid storage chamber (6) and The whole cavity is sealed, and heat dissipation blades (7) are arranged on the other side of the heat dissipation distribution cavity (8); an appropriate heat conducting liquid is added into the sealed cavity formed by the heat dissipation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com