Aspheric surface detecting instrument

An aspheric surface and detector technology, applied in instruments, measuring devices, optical devices, etc., can solve the problems of low detection accuracy and efficiency of optical aspheric surfaces, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

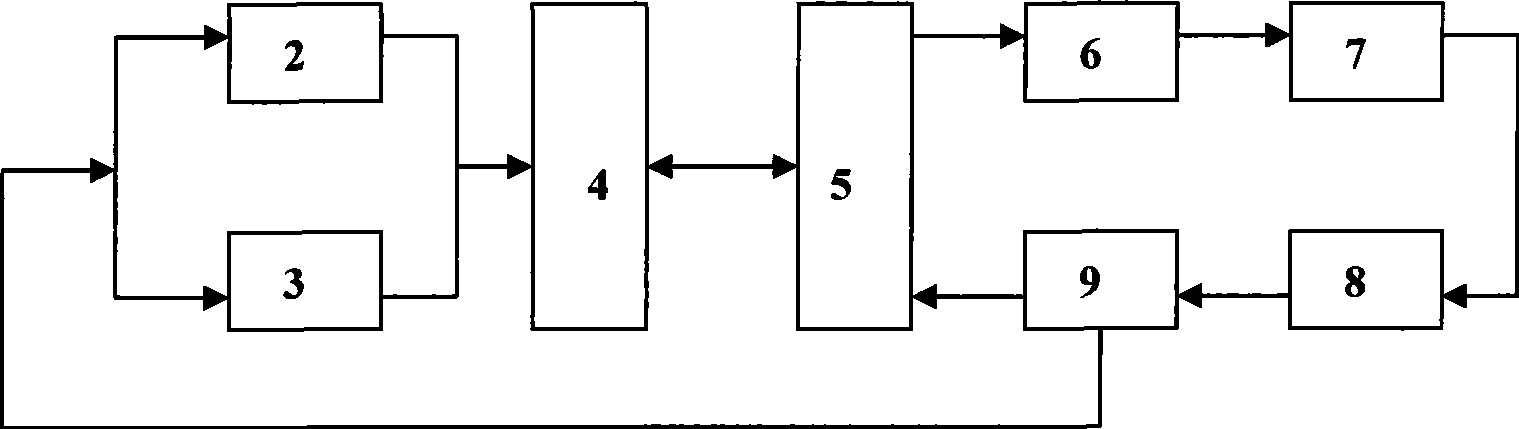

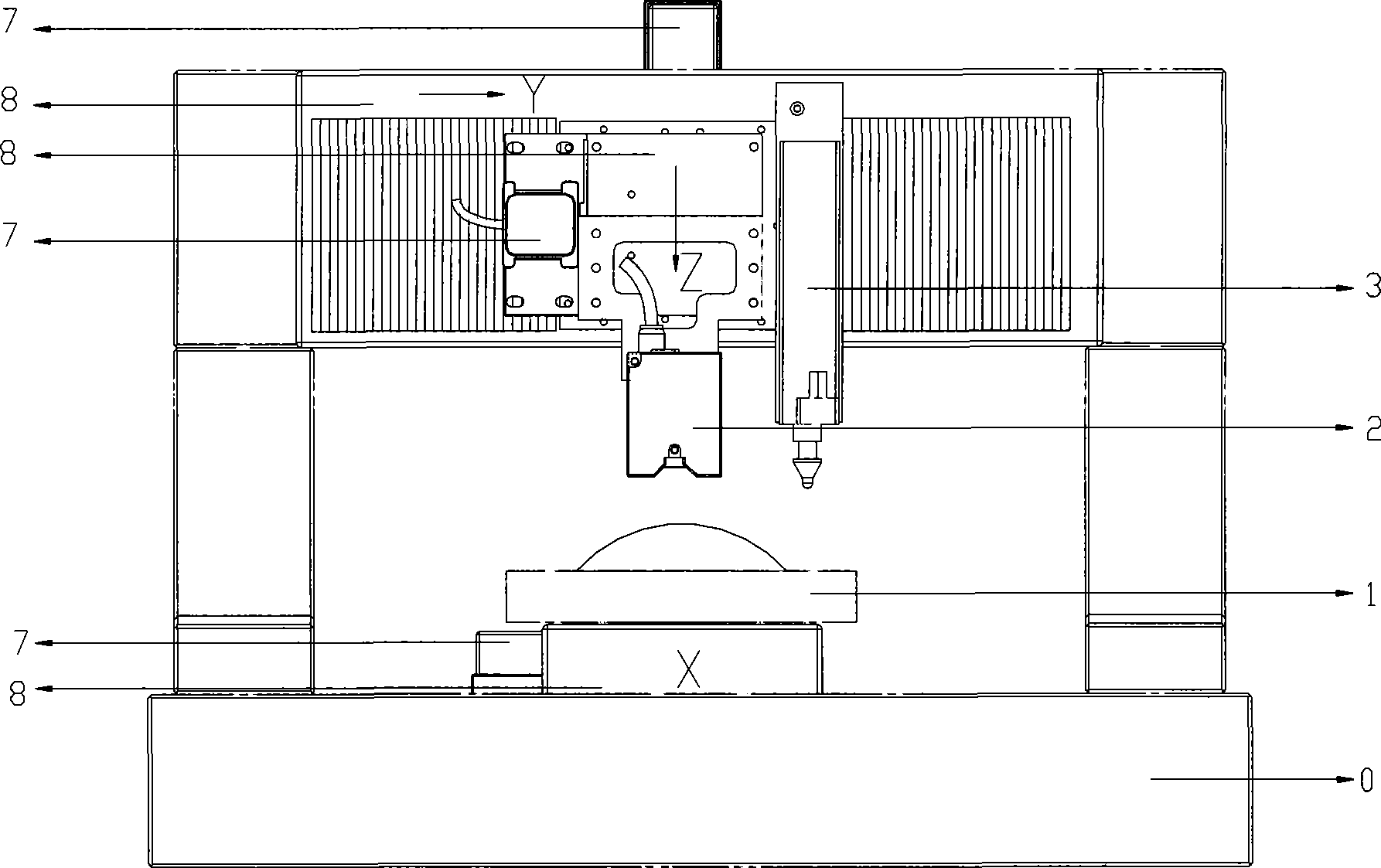

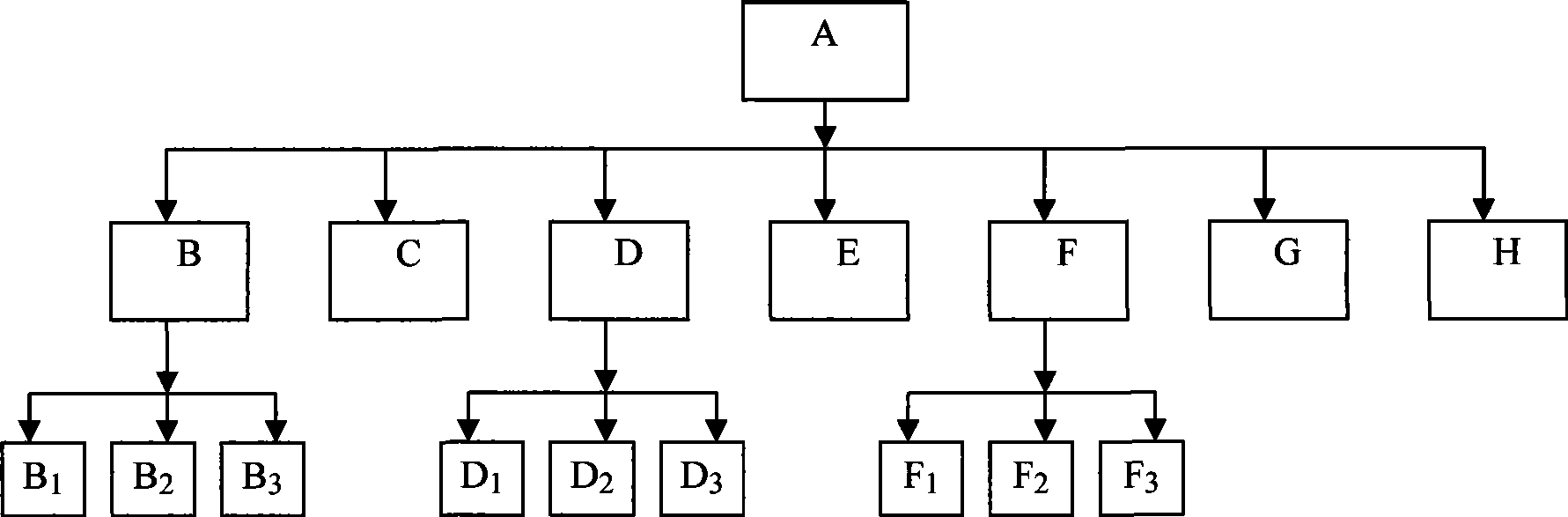

[0021] see figure 1 with 2 , the present invention is equipped with a granite structure frame 0, a granite ultra-precision detection platform 1, an automatic focusing non-contact laser displacement measuring head 2, a grating contact displacement measuring head 3, a computer 4, a four-axis motion control card 5, a driver 6, and a press Electric ceramic motor 7, XYZ axis motion mechanism 8 and grating ruler 9.

[0022] The XYZ three-axis movement mechanism 8 is installed and fixed on the granite structure frame 0, the automatic focusing non-contact laser displacement measuring head 2 and the grating contact displacement measuring head 3 are respectively installed and fixed on the Z-axis movement mechanism, and the granite ultra-precision detection platform 1 is set On the X-axis motion mechanism; the XYZ three-axis motion mechanism 8 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com