Liquid crystal display panel and its test method

A technology of a liquid crystal display panel and a test method, which is applied in the directions of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of slow test speed, electrode scratches, and rapid probe consumption, and achieves low cost, high reliability, and high reliability. Test the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

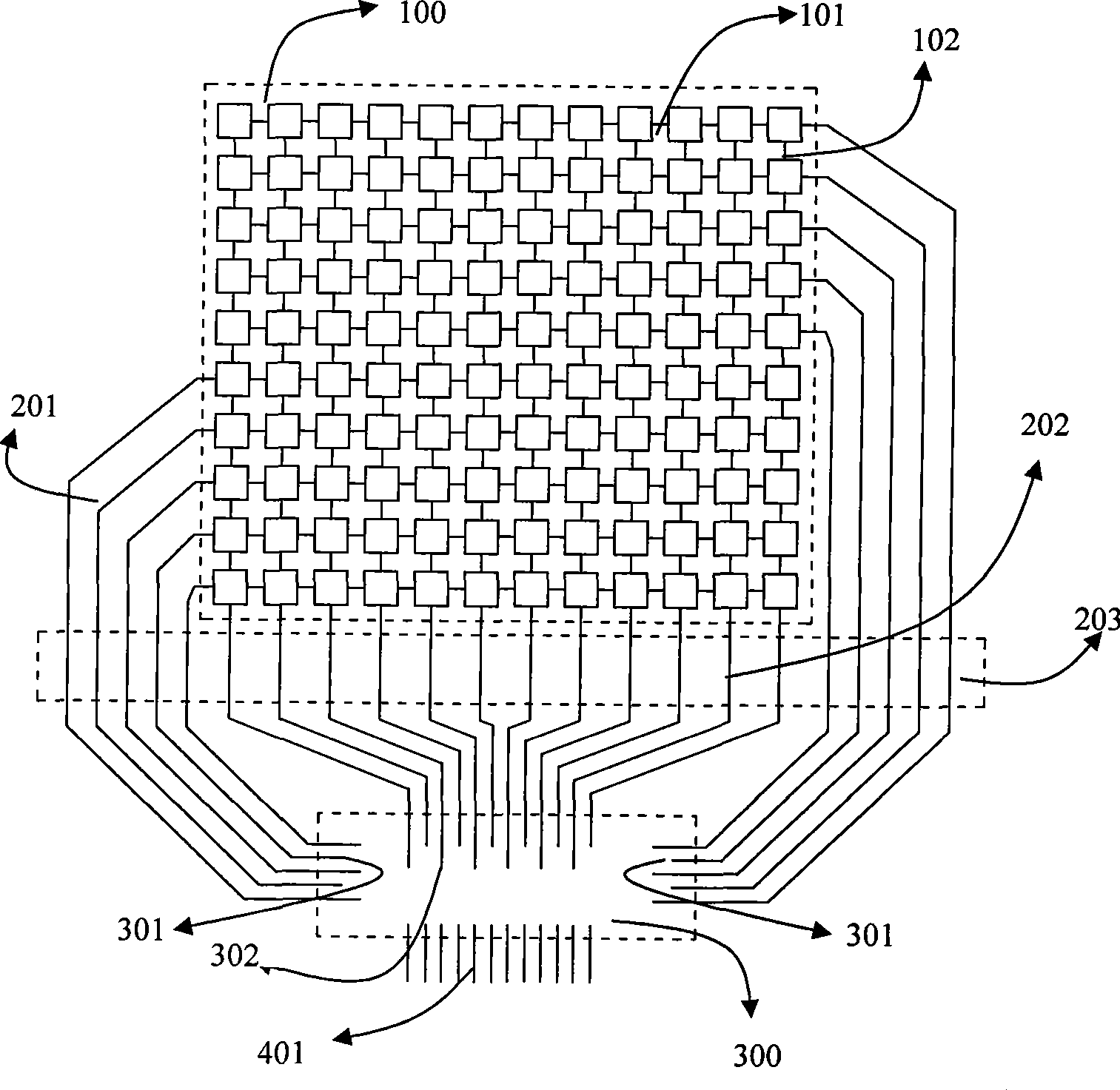

[0059] Form row electrodes 101 and column electrodes 102 on the panel, connect the column electrodes with the design electrodes of the integrated circuit packaging area 300, and connect the connection lines between the row electrodes and the integrated circuit packaging area from the left and right respectively according to the upper and lower screens of the display area. Under the circuit packaging area, extend the distance between the row and column electrodes and the connecting wires of the integrated circuit, the odd-numbered rows or columns or the even-numbered rows or columns.

[0060] The test is divided into two steps:

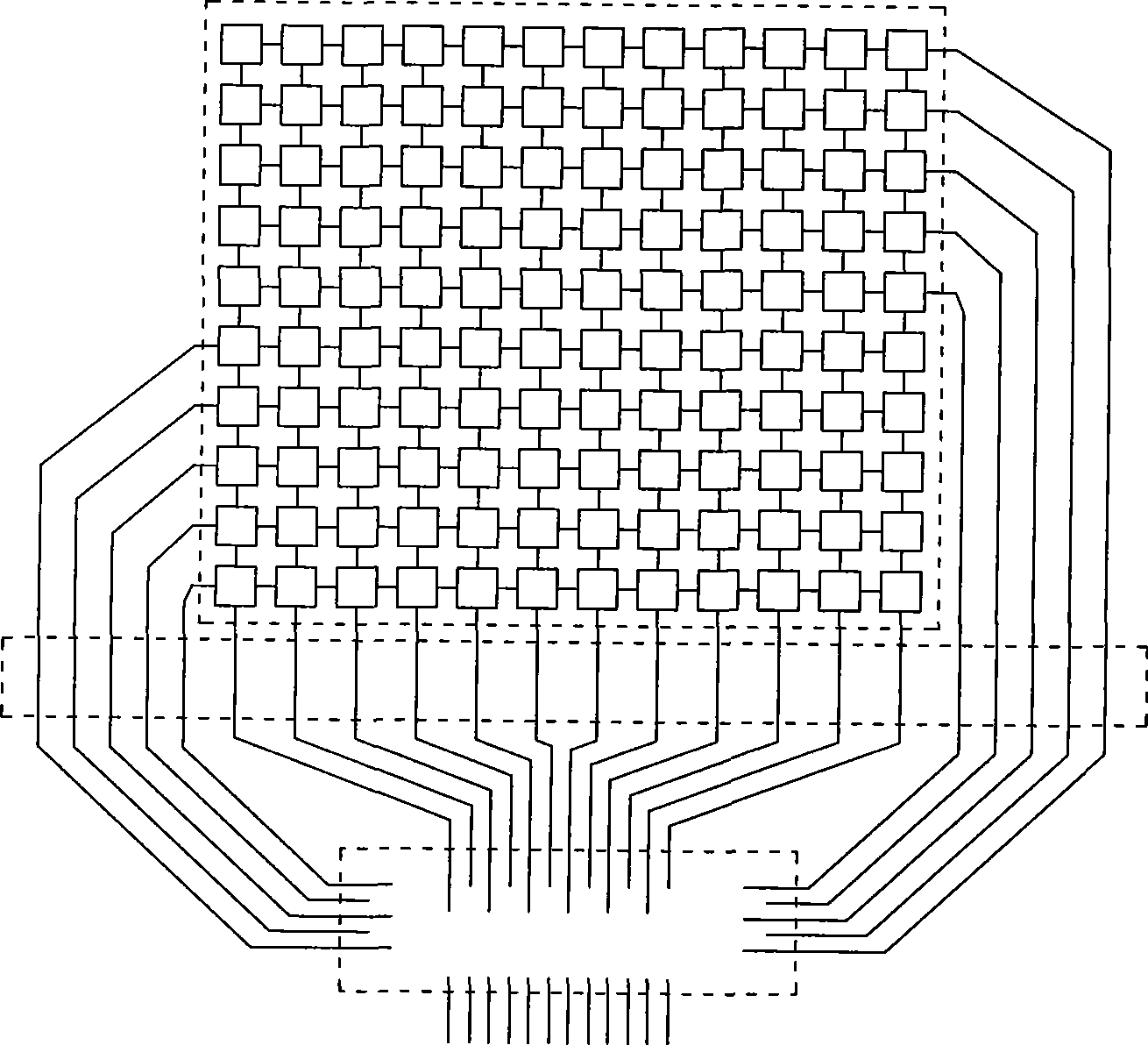

[0061] When no voltage is applied, all dot matrixes, that is, the intersections of row electrodes and column electrodes, have no display patterns, such as figure 2 As shown, this figure is for comparison with the pattern shown.

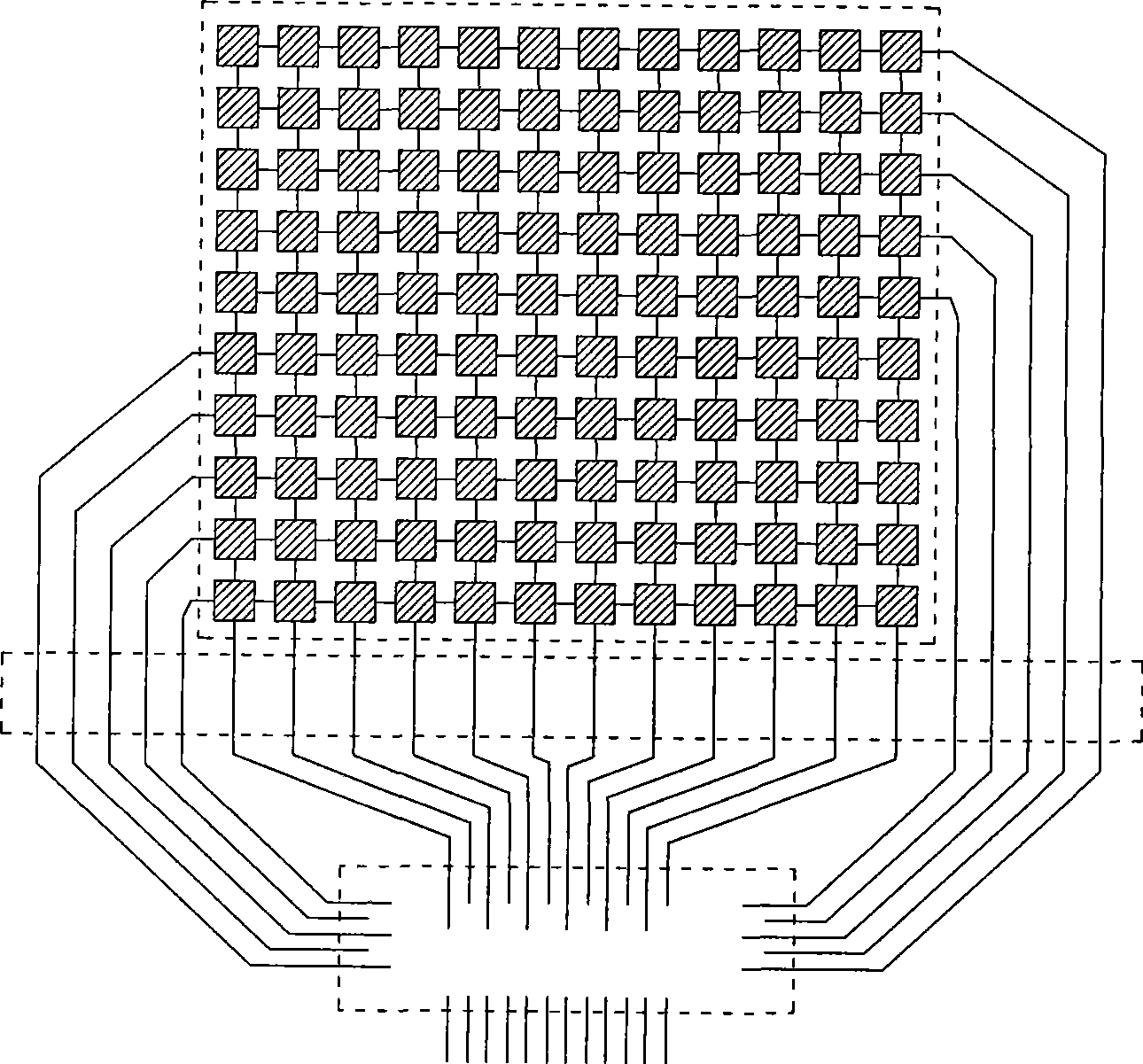

[0062] The first step is to apply AC voltage to all selected test areas 203 and observe under crossed polarizers. The resul...

Embodiment 2

[0071] Row electrodes 101 and column electrodes 102 are formed on the panel, and the column electrodes are connected to the design electrodes of the integrated circuit packaging area 300. The connection lines between the odd-numbered rows of the row electrodes and the integrated circuit packaging area are drawn from the side of the display area, and the even-numbered rows are connected to the integrated circuit packaging area. The connection lines of the packaging area are drawn from the other side of the display area. Under the integrated circuit packaging area, the connection wires between the column electrodes and the integrated circuit are extended (odd-numbered rows (columns) or even-numbered rows (columns) are extended), and the connection wires between the row electrodes and the integrated circuit do not need to be extended at intervals.

[0072] The test is divided into two steps:

[0073] The first step is to apply AC voltage to all selected test areas 203 and observe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com