LCD device

A liquid crystal display and liquid crystal panel technology, applied in the direction of instruments, lighting devices, optics, etc., can solve the problems of light-emitting diode light-emitting function, lifespan, quality reduction, increased manufacturing cost, and the distance between the light-emitting surface and the display panel is shortened, so as to avoid Headlight effect, lower production cost, perfect mixed light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

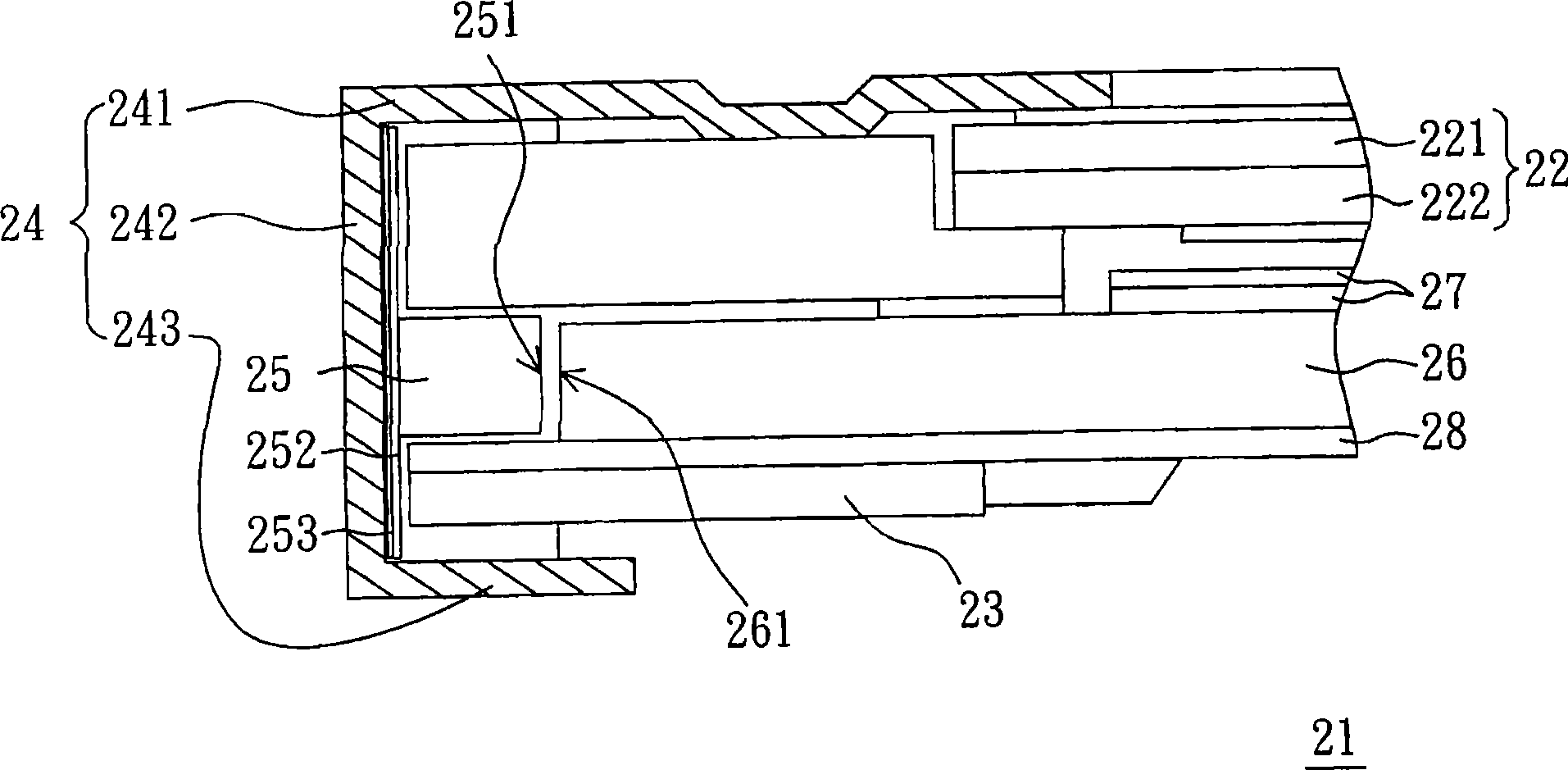

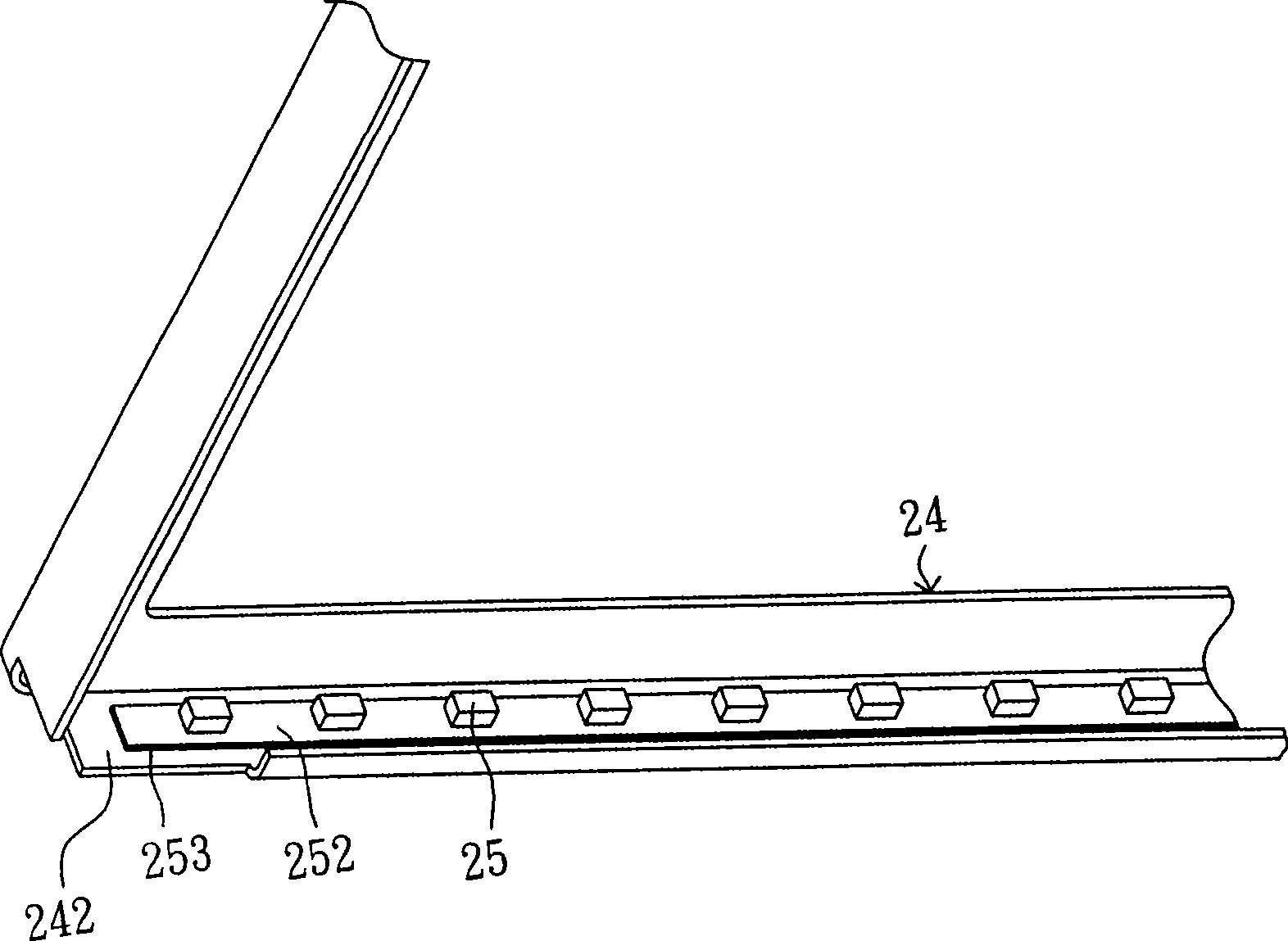

[0021] Please refer to figure 2 , figure 2 It is a cross-sectional view of the structure of a liquid crystal display according to an embodiment of the present invention. Depend on figure 2 It can be seen that the liquid crystal display 21 of this embodiment mainly includes a first frame 23 , a light guide plate 26 , a second frame 24 , a plurality of LEDs 25 and a liquid crystal panel 22 . The light guide plate 26 is disposed on the first frame 23 , and the light guide plate 26 has a light incident surface 261 . The second frame 24 is disposed above the light guide plate 26 . The light emitting diodes 25 are disposed inside the second frame 24 and adjacent to the light incident surface 261 of the light guide plate 26 . Wherein, the light emitting diode 25 can be a surface mount type light emitting diode component.

[0022] Based on the above, the liquid crystal panel 22 is mainly used for displaying images, located in the accommodating space of the second frame 24 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com