Power economizer for low matching system

A technology of energy saver and drive, applied in the direction of harmonic reduction devices, AC network circuits, electrical components, etc., can solve the problems of reducing the safe current carrying capacity of conductors, increasing the extra copper loss of motors, and reducing the efficiency of motors, so as to reduce mechanical wear and various noises, reduce power consumption, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings.

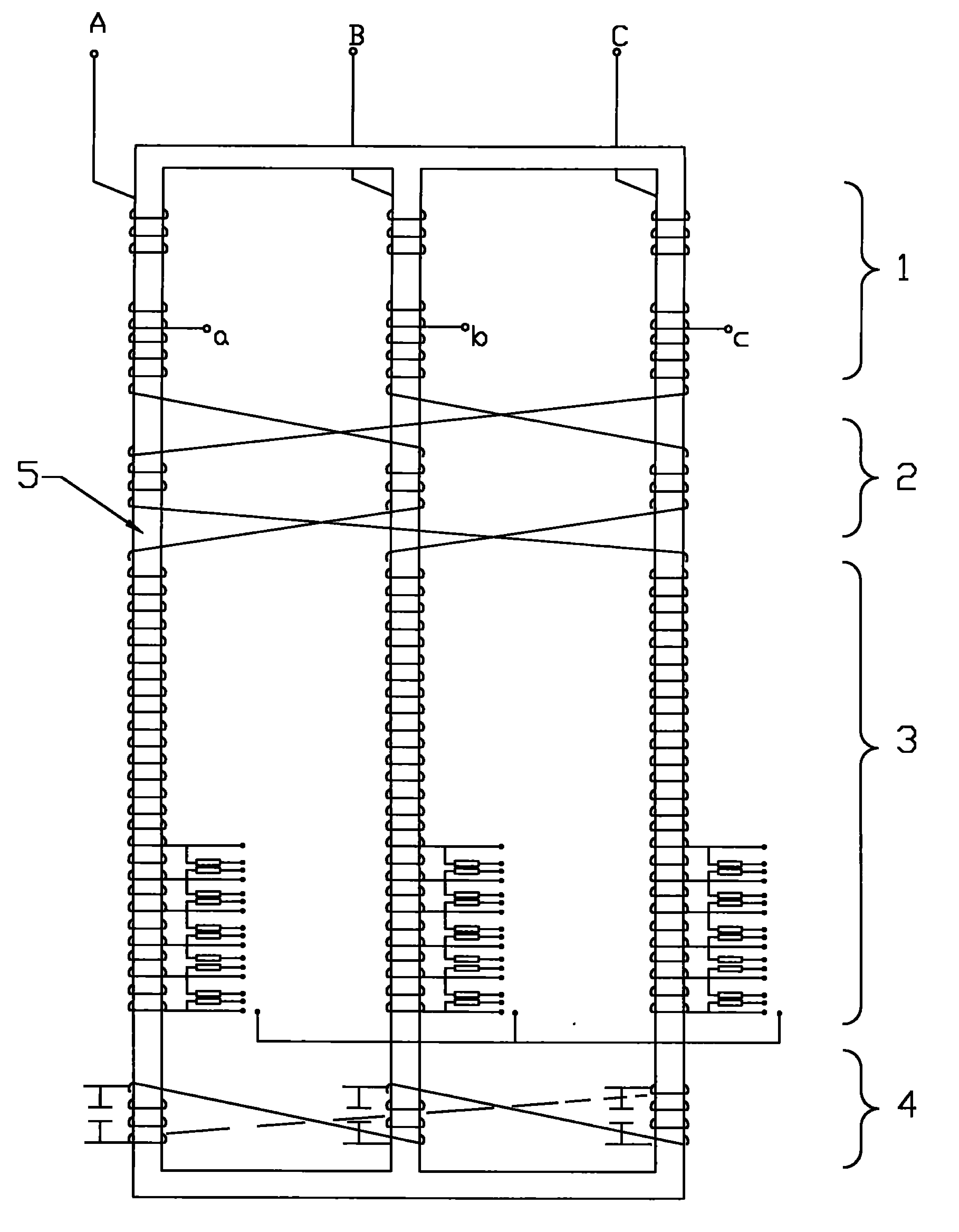

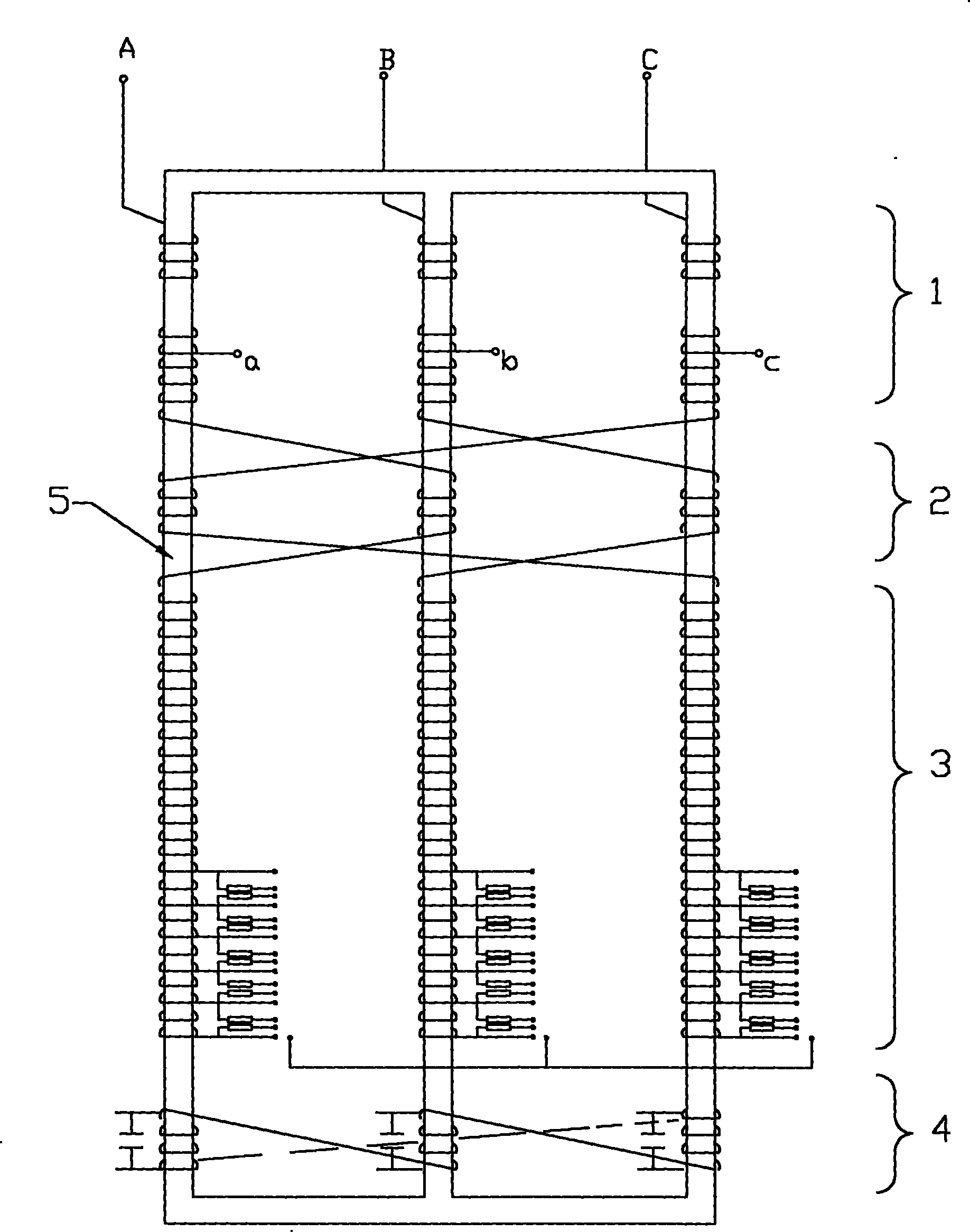

[0061] As shown in Figure 1, the energy saver of the low distribution system includes an automatic constant current incoming line resistor 1, an electromagnetic balance winding 2, an automatic constant voltage on-load adjustment device 3, a grid purification device 4 and an iron core 5, wherein:

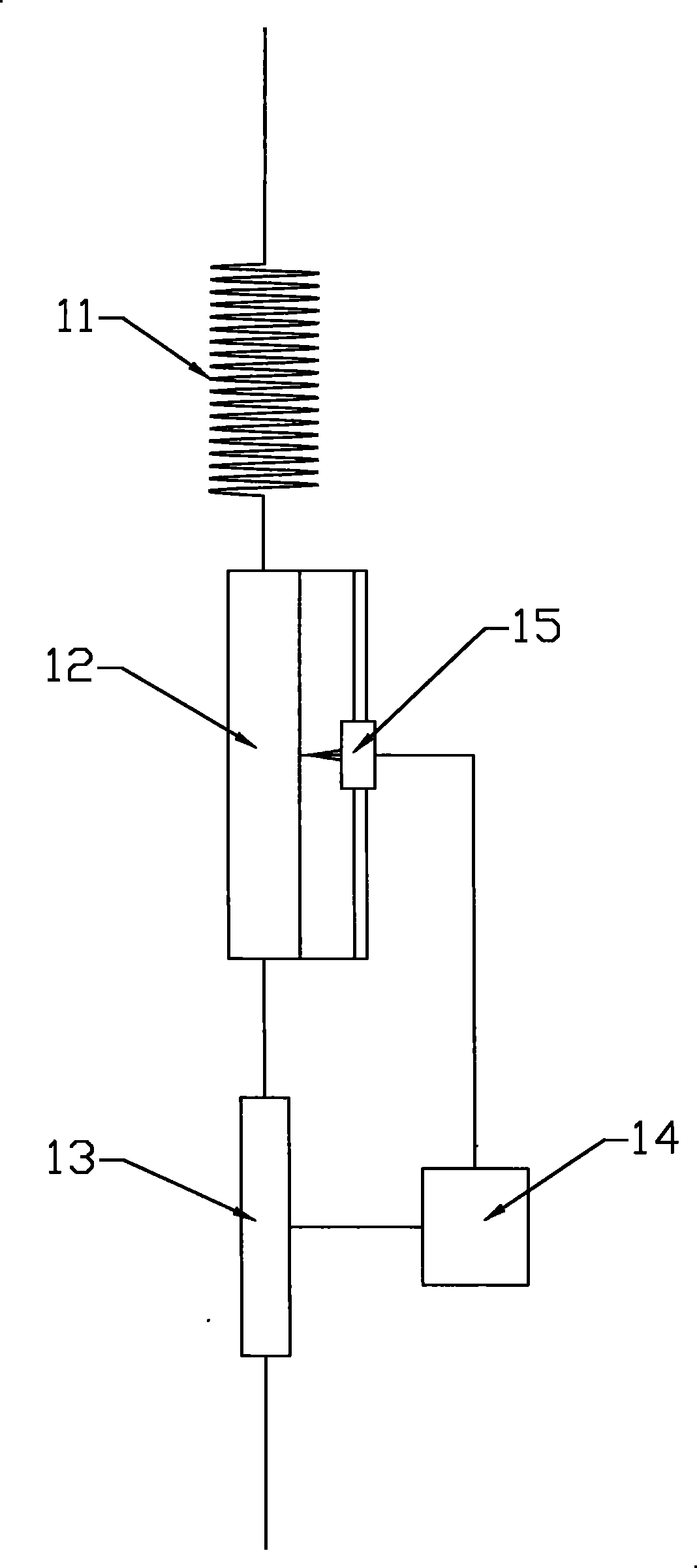

[0062] The automatic constant current incoming line resistor 1 (see Fig. 2) is to connect the starting winding 11, the sliding wire rheostat 12 and the current transducer 13 in series, and the current transducer 13 is connected to drive the sliding wire rheostat 12 through the transmission mechanism. The active servo motor is the driver 15 , and a current sampling control module 14 is also connected between the driver 15 and the current transmitter 13 .

[0063] The automatic constant current incoming line resistor is connected to each line of the power distribution system (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com