In-situ digitalization method and apparatus for transforming plant primary equipment

A technology of primary equipment and substation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

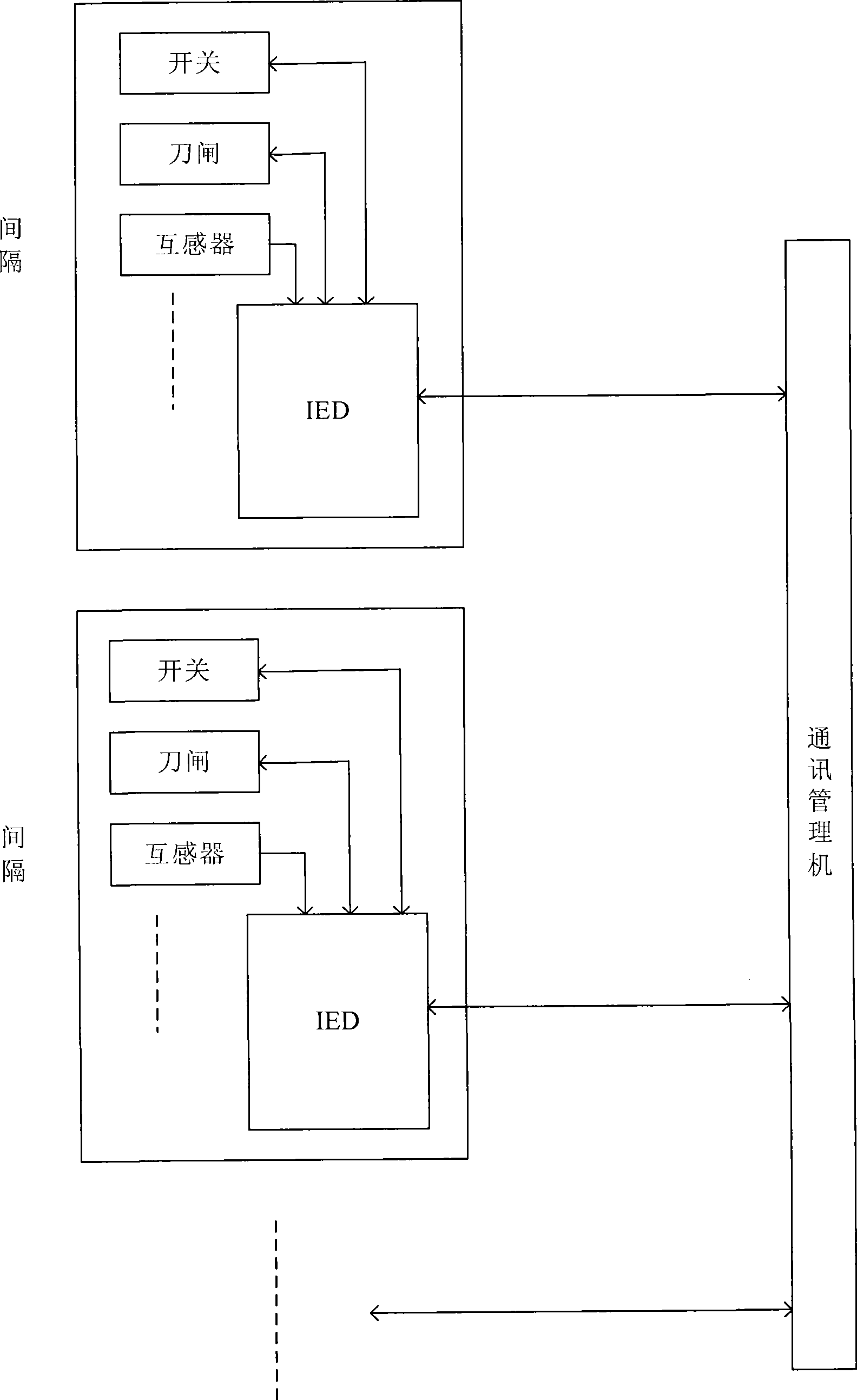

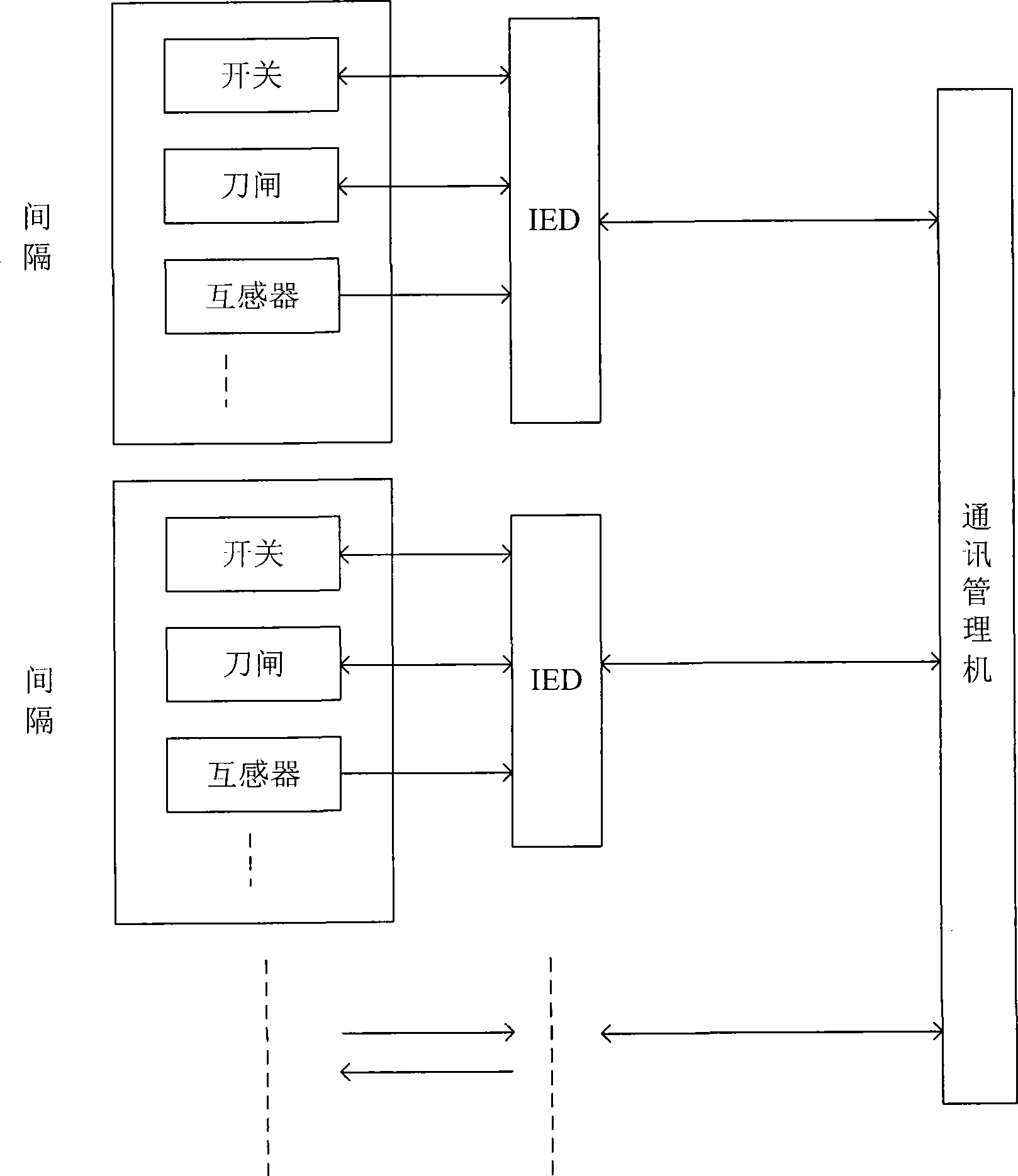

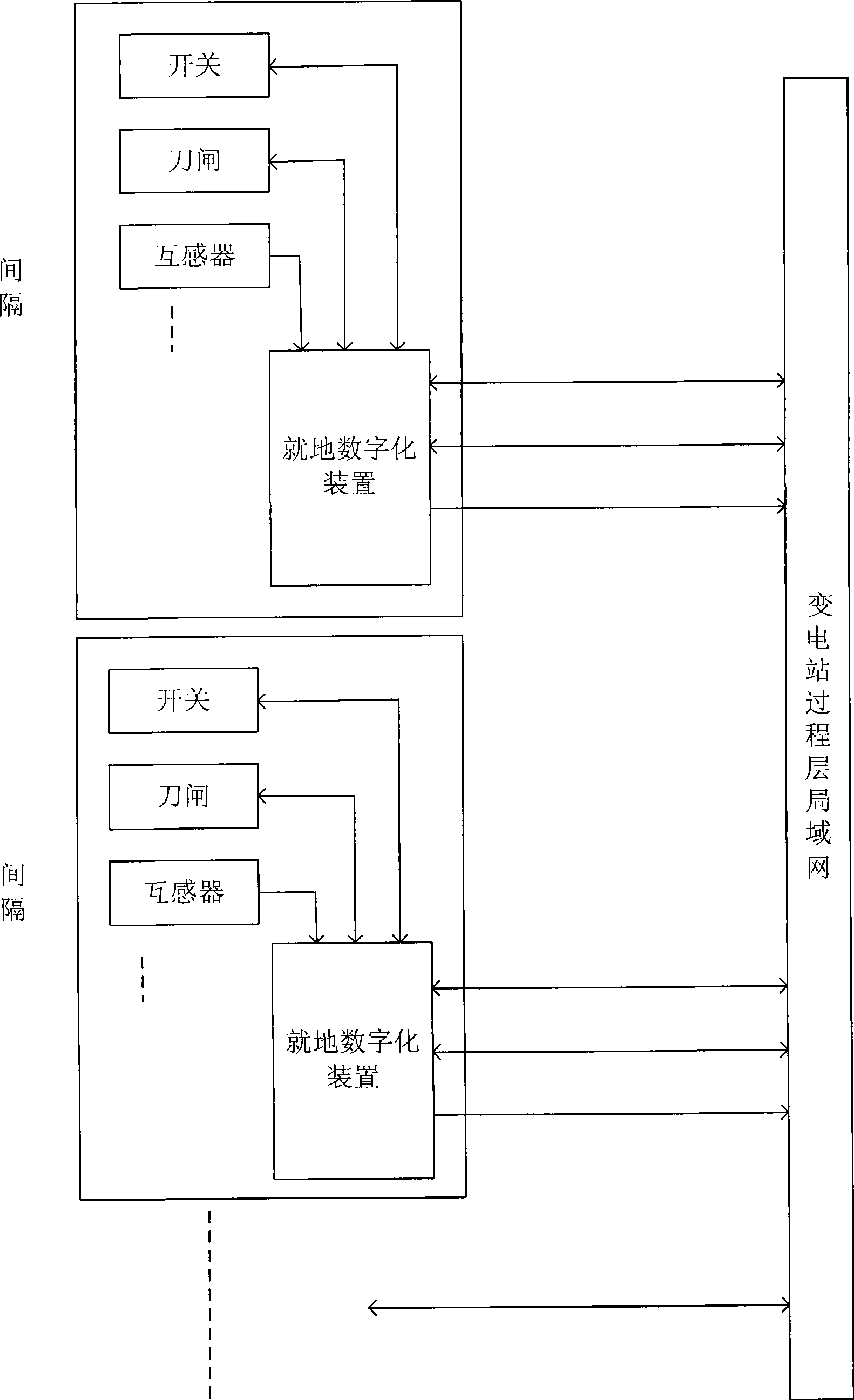

[0041] The present invention will be described below in conjunction with the accompanying drawings. image 3 It is a schematic diagram of the connection between the in-situ digitization device and other equipment of the present invention; Figure 4 It is a module block diagram of the in-situ digitization device of the present invention; Figure 5 It is a block diagram of the analog quantity access unit in the local digitization device of the present invention; Figure 8 It is a schematic diagram of in-situ digitization of each interval of the present invention.

[0042] Such as image 3 As shown, the in-situ digitization device of the present invention is arranged in each compartment, that is, as Figure 8 As shown, the incoming line interval, the high-voltage PT interval, the high-voltage bus coupling interval, the main transformer high-voltage main incoming interval, the main transformer low-voltage main incoming interval, the main transformer body interval, the utility p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com