Drive method and drive device capable of regulating high-power LED lighteness

A driving method and a technology of a driving device, which are applied in the direction of lighting devices, lamp circuit layout, light sources, etc., can solve problems such as difficulty in increasing the refresh rate of gray levels, limiting the maximum frequency of PWM signals, and deteriorating devices or equipment, etc., to achieve improvement Electromagnetic compatibility performance, increase the refresh rate of grayscale, and prolong the effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

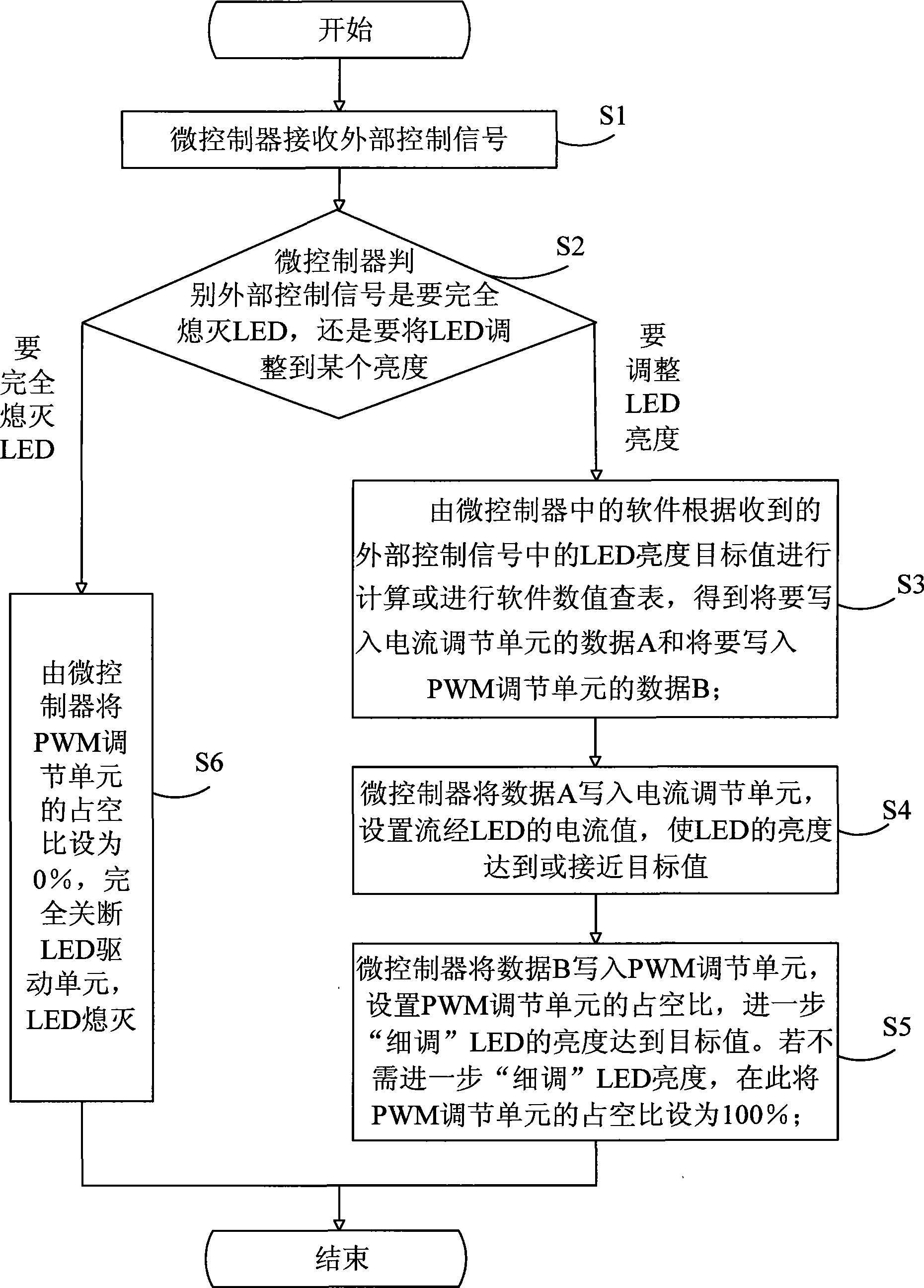

[0024] refer to figure 1 , the driving method capable of adjusting the brightness of high-power LED provided by the present invention comprises the following steps:

[0025] In step S1: the microcontroller receives an external control signal;

[0026] In step S2: the microcontroller judges the received control signal. Determine whether the external control signal is to completely turn off the LED or adjust the LED to a certain brightness, if it is necessary to completely turn off the LED, then perform step S6, and if it is necessary to adjust the LED to a certain brightness value, then perform step S3;

[0027] In step S6: the microcontroller sets the duty cycle of the PWM adjustment unit to 0%, completely turns off the LED drive unit, and the LED goes out, and completes a brightness adjustment process;

[0028] In step S3: the software in the microcontroller calculates according to the LED brightness target value in the received external control signal or performs a softwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com