Coating metallic plate

A metal plate and coating technology, applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problem of uneven powder spraying or painting of products, rough appearance of products, process pollution of powder spraying or painting, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a coated metal plate, which can meet the requirement of producing shells of products such as computer cases that need to be tested for electromagnetic interference.

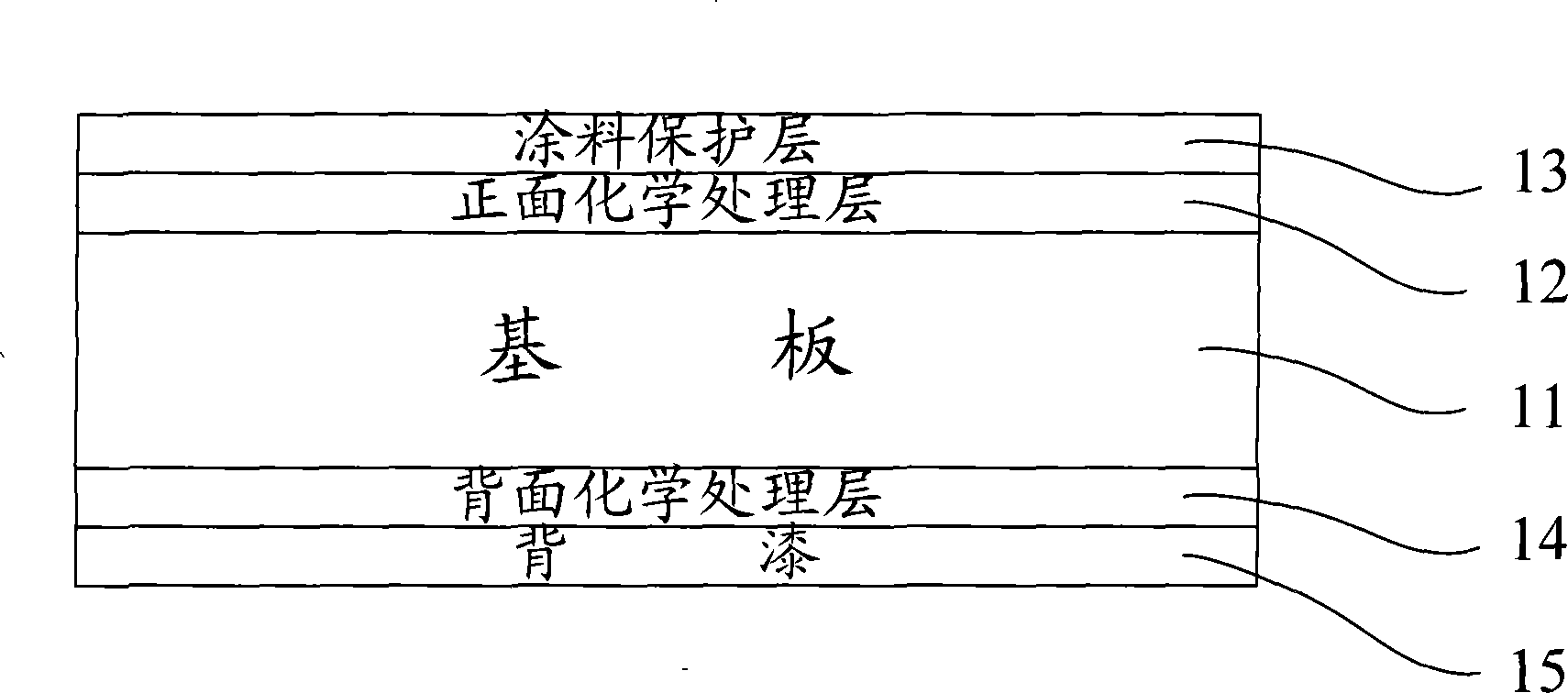

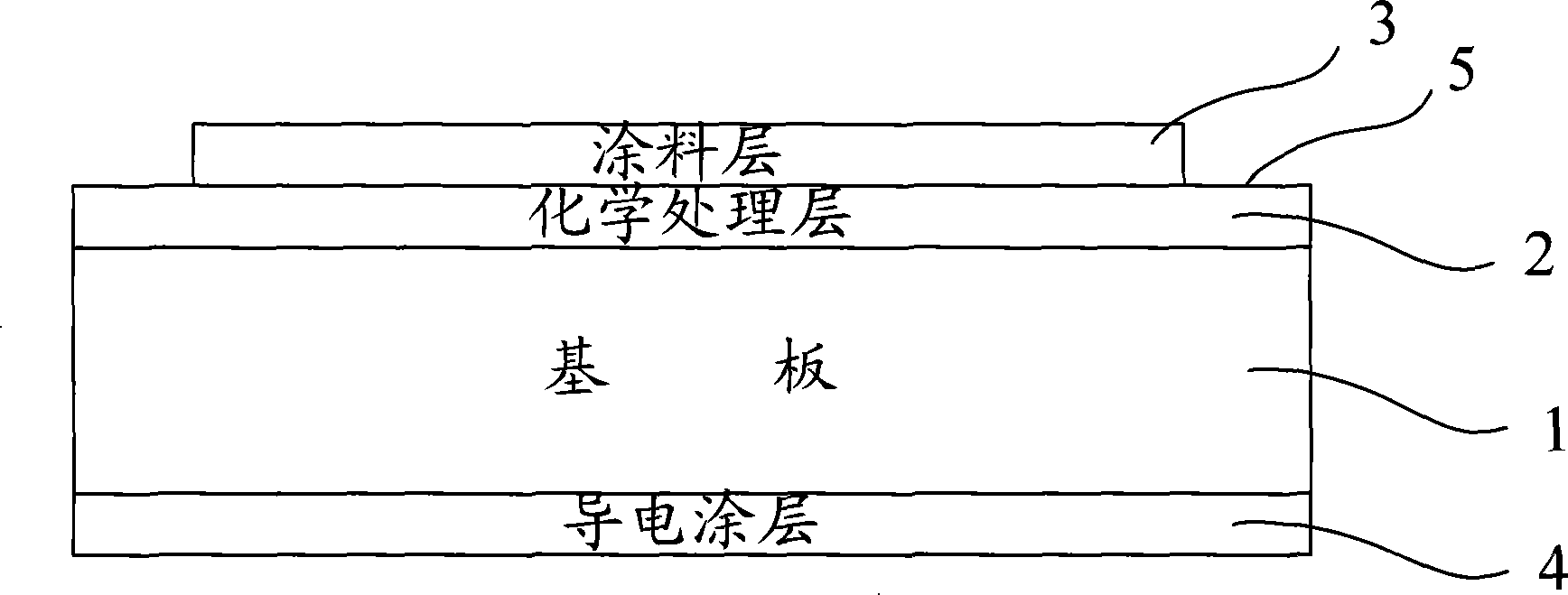

[0021] see figure 2 and image 3 , figure 2 It is the structural diagram of the first embodiment of the coated metal plate of the present invention; image 3 It is the front view of the first embodiment of the coated metal plate of the present invention.

[0022] figure 2 The structure diagram of the first embodiment of the coated metal plate shown is specifically a cross-sectional schematic diagram of the coated metal plate according to the embodiment of the present invention.

[0023] The coated metal plate described in the first embodiment of the present invention comprises a substrate 1, a chemical treatment layer 2 on the front of the substrate 1, a conductive coating 4 on the back of the substrate 1, and a paint layer 3 on the outside of the chemical treatment layer 2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com