Fuel filter

A fuel filter, filter housing technology, applied in membrane filters, filtration separation, liquid fuel feeders, etc., can solve the problems of running under conditions, unintentionally or intentionally, not being properly installed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

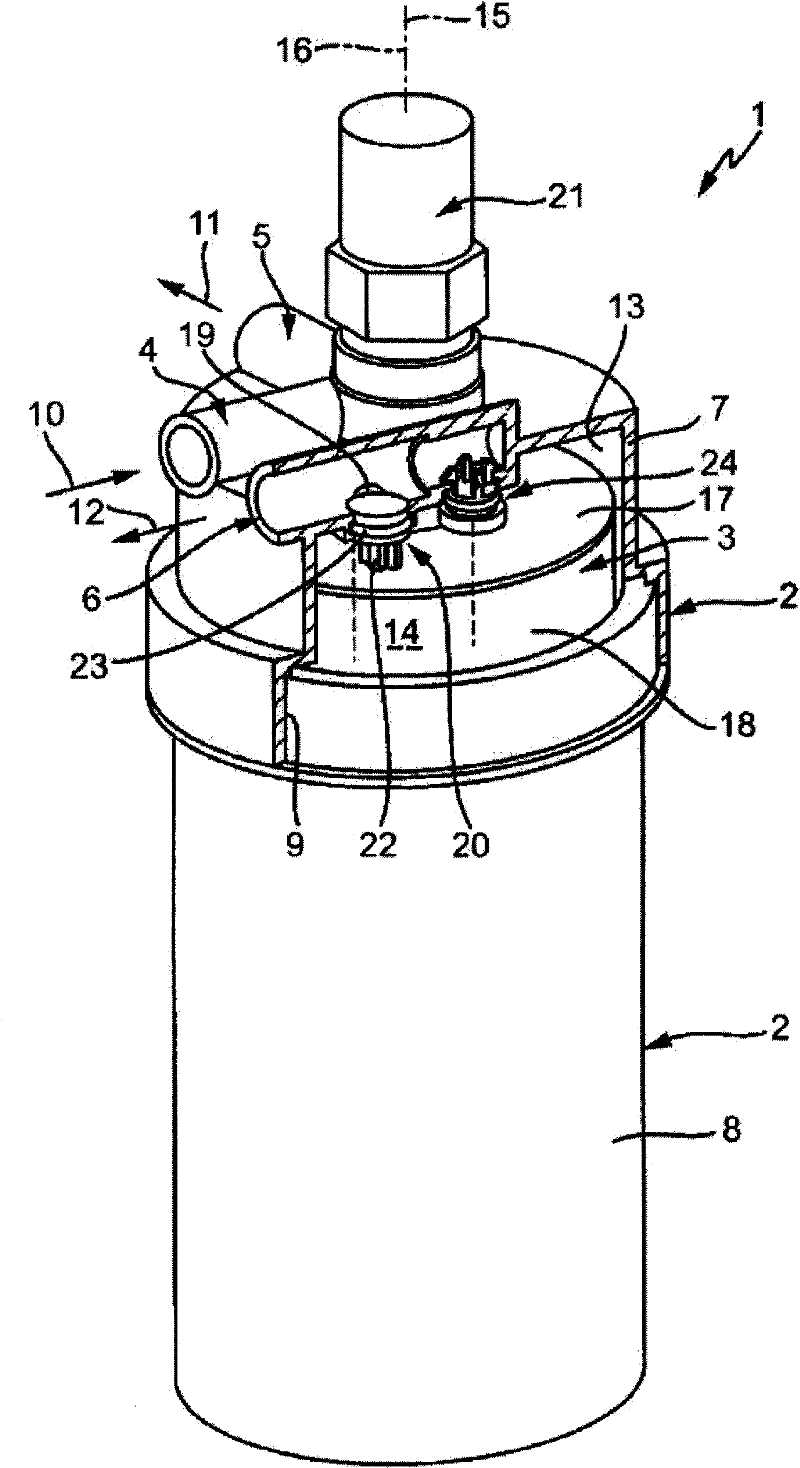

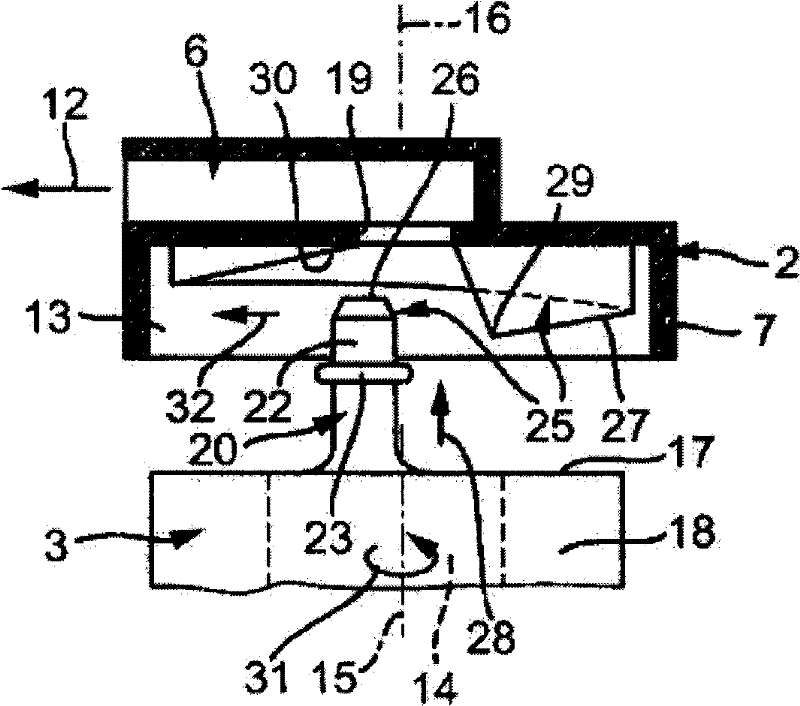

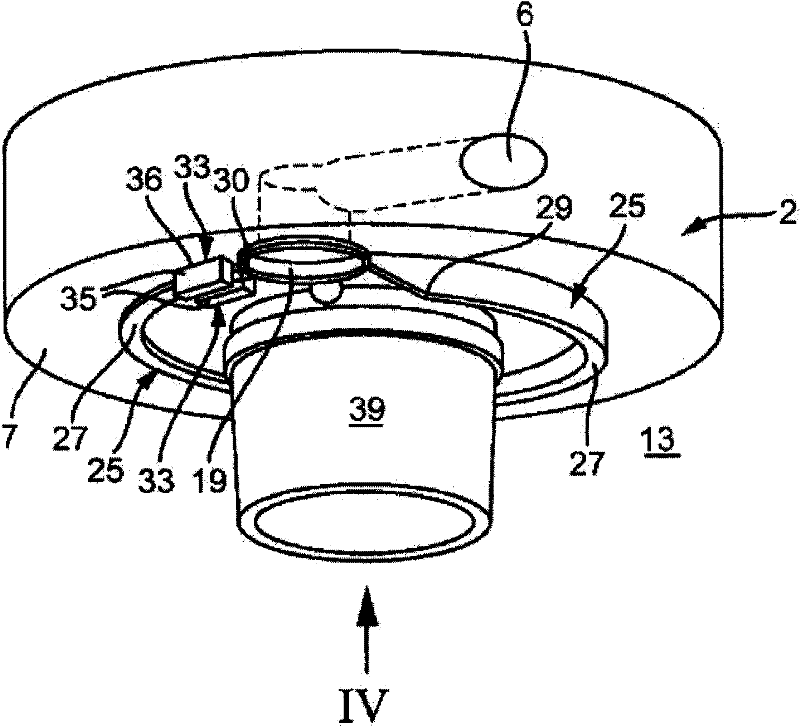

[0018] according to figure 1 , a fuel filter 1, which is suitable for filtering liquid fuel, such as gasoline or diesel, the fuel filter includes a filter housing 2 and a filter element 3. The filter housing 2 includes an inlet 4 on the untreated side, an outlet 5 on the treated side, and an oil return pipeline 6 on the untreated side. The filter housing 2 is assembled from a cup-shaped lid 7 and a cup-shaped bottom 8 which can be screwed together by means of a threaded connection 9 . Inlet 4 , outlet 5 and oil return line 6 are here formed on cover 7 . The filter housing 2 is preferably provided in a pendant mounted position so that for maintenance of the fuel filter 1 the bottom 8 can be screwed off while the upper cover 7 remains stationary. Alternatively, an upright mounting position can also be provided, whereby the cover 7, including connections 4, 5, and 6, is placed on the bottom, remaining stationary, functionally equivalent to forming a "bottom of the housing", whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com