Tube-type solid polymer fuel cell and method for manufacturing tube-type solid polymer fuel cell

A solid polymer and fuel cell technology, which is applied in the direction of solid electrolyte fuel cells, fuel cell parts, fuel cell shapes/forms, etc., can solve problems such as difficult filling and complicated manufacturing steps, and achieve improved power generation performance and improvement Power generation performance, effect of improving diffusion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

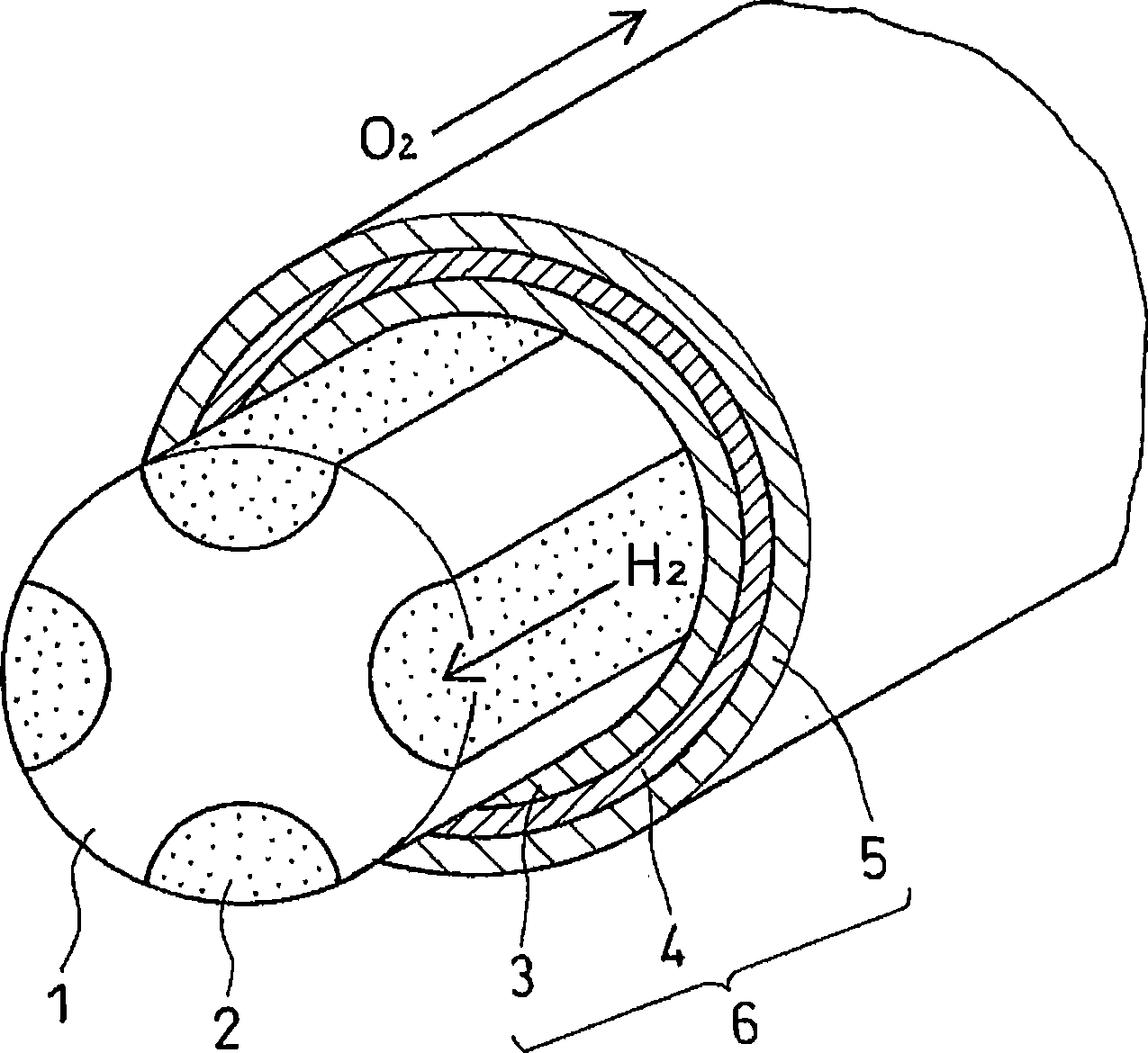

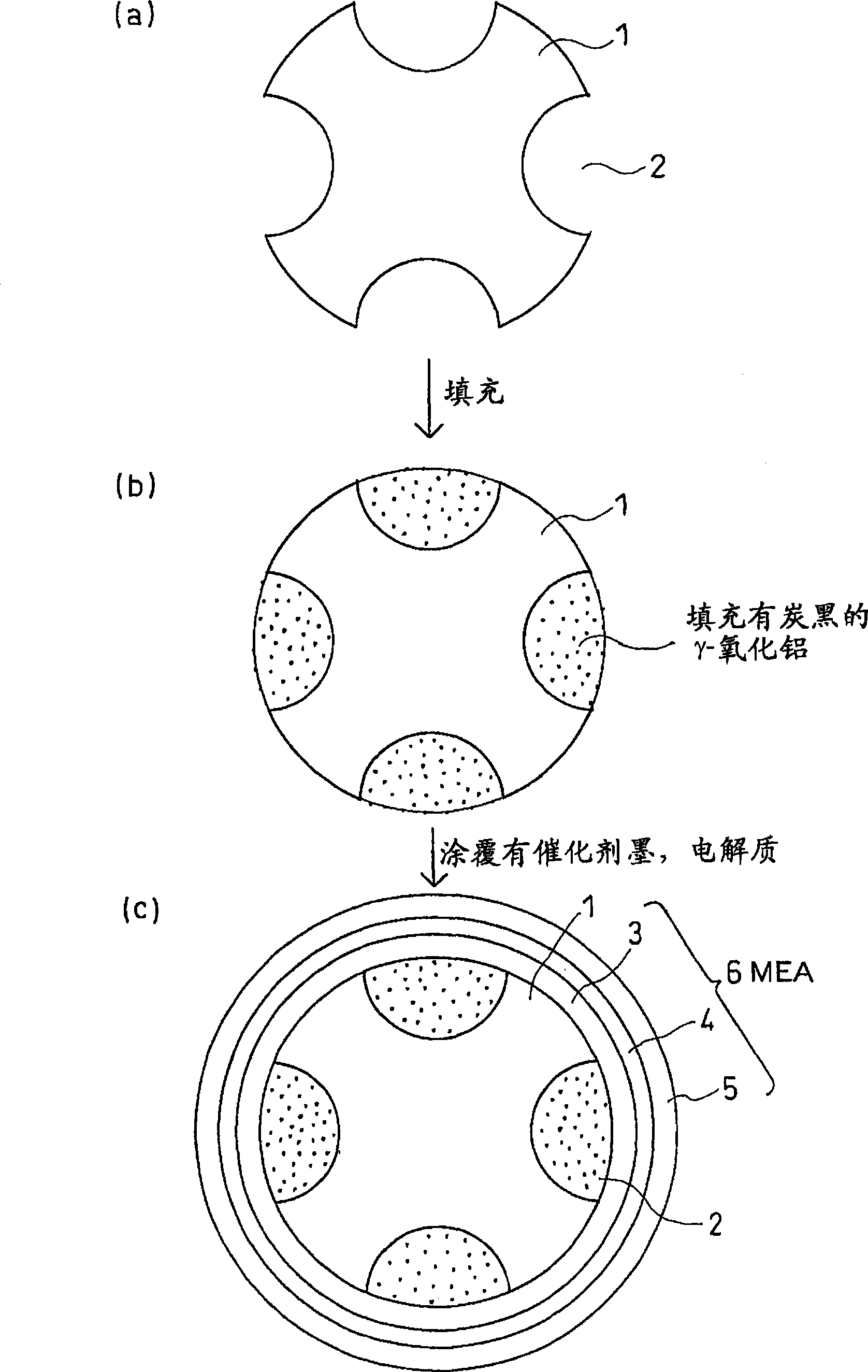

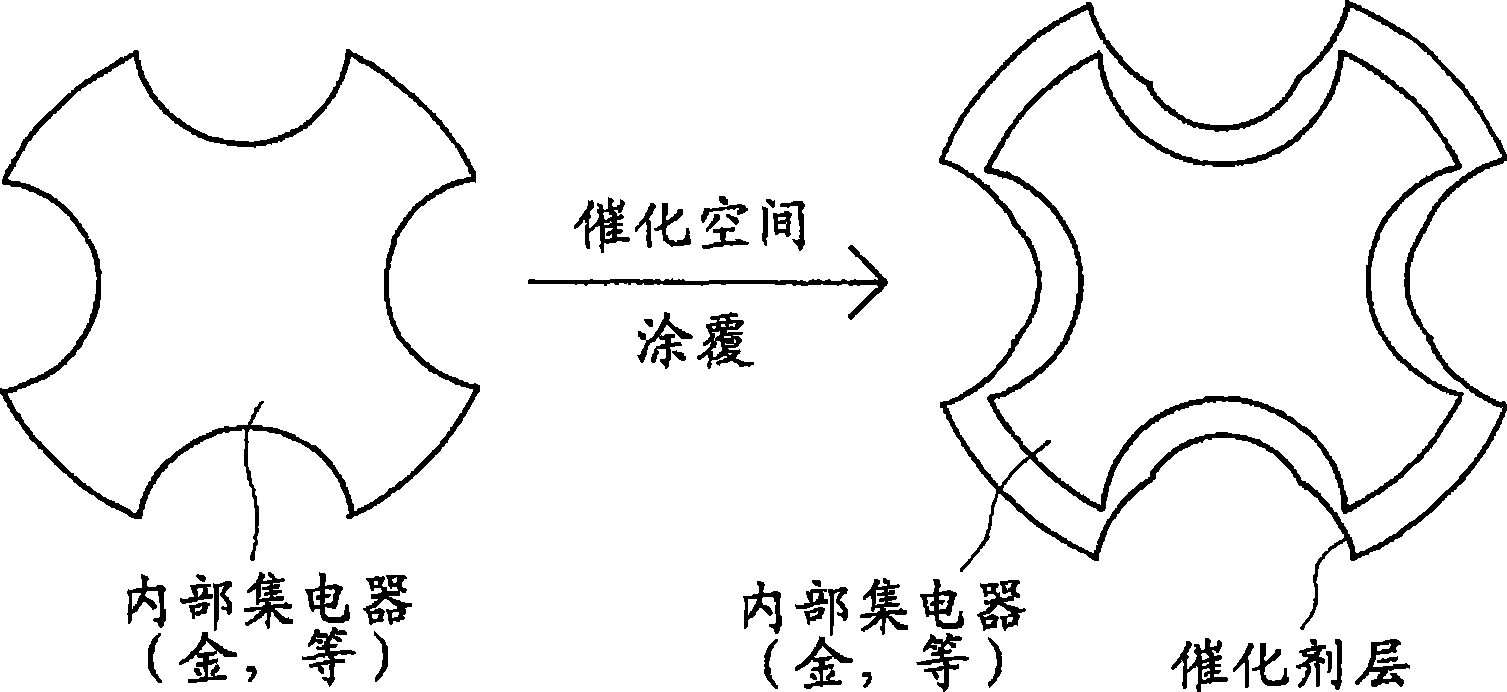

[0057] Similar to Comparative Example 3, Figure 5 shows a structure in which the gaps serving as the gas passages of the internal current collectors in a tubular fuel cell are filled with γ-alumina mixed with a corrosion-resistant conductive particles. Figure 5 A method for its manufacture is also shown. In the present invention, in order to clean the gas channels of the inner current collector and ensure the conductivity of the gas channels, these gas channels are filled with fine-pored γ-alumina in which corrosion-resistant conductive particles. The structure thus obtained can prevent infiltration of catalyst slurry during MEA fabrication, ensure gas diffusibility during power generation without any cleaning step after MEA fabrication, and reduce cell resistance during fuel cell operation.

[0058] Specifically, conductive particles having corrosion resistance such as carbon powder (for example, Ketjen EC) are mixed in a γ-alumina solution prepared by a usual preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com