Atactic amorphous copolyester as well as preparation method and application thereof

A technology of amorphous copolyester, applied in the field of amorphous copolyester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, PETG x N y

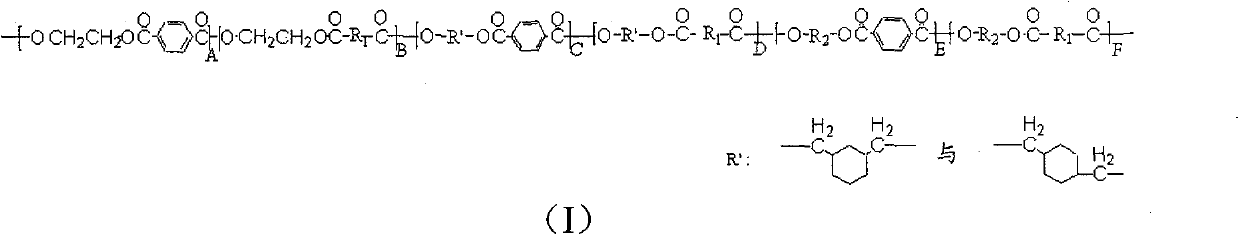

[0043] The structural formula of this amorphous copolyester is shown in formula (II):

[0044]

[0045]

[0046] The amorphous copolyester of this embodiment is synthesized from two kinds of diacid monomers and two kinds of diol monomers, and the diacid monomers include terephthalic acid (TPA) and dimethyl 2,6-naphthalene dicarboxylate ( NDC); diol monomers include ethylene glycol (EG) and 1,3 / 1,4-cyclohexanedimethanol (1,3 / 1,4-CHDM) (Dow Chemical Company, UNOXOL TM 34 Diol). The molar percentages of terephthalic acid (TPA), dimethyl 2,6-naphthalene dicarboxylate (NDC), ethylene glycol (EG) and 1,3 / 1,4-cyclohexanedimethanol are shown in Table 1 . As can be seen from Table 1, the glass transition temperature of the copolyester can be changed by adjusting the content of 2,6-dimethyl naphthalene dicarboxylate, for example, the higher the content of 2,6-dimethyl naphthalene dicarboxylate, the higher the glass transition temperature. T...

Embodiment 2

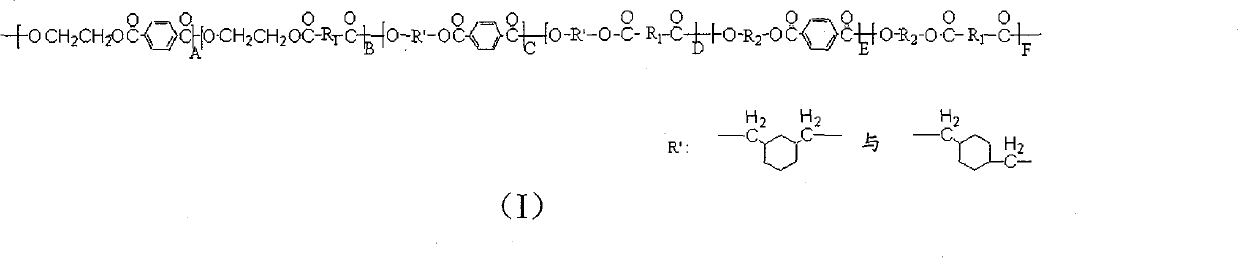

[0057] Embodiment 2, PETG x S y

[0058] The structural formula of this amorphous copolyester is shown in formula (III):

[0059]

[0060] The amorphous copolyester of this embodiment is synthesized by two kinds of diacid monomers and two kinds of diol monomers, and diacid monomers comprise terephthalic acid (TPA) and succinic acid (SA); Including ethylene glycol (EG) and 1,3 / 1,4-cyclohexanedimethanol (1,3 / 1,4-CHDM) (Dow Chemical Company, UNOXOL TM 34 Diol), wherein the molar percentages of terephthalic acid (TPA), succinic acid (SA), ethylene glycol (EG) and 1,3 / 1,4-cyclohexanedimethanol are shown in Table 2. It can be seen from Table 2 that the glass transition temperature of the copolyester can be changed by adjusting the content of succinic acid, for example, the higher the content of succinic acid, the lower the glass transition temperature. The diacid monomer and the diol monomer are produced through two-stage esterification and polycondensation reaction, and a te...

Embodiment 3

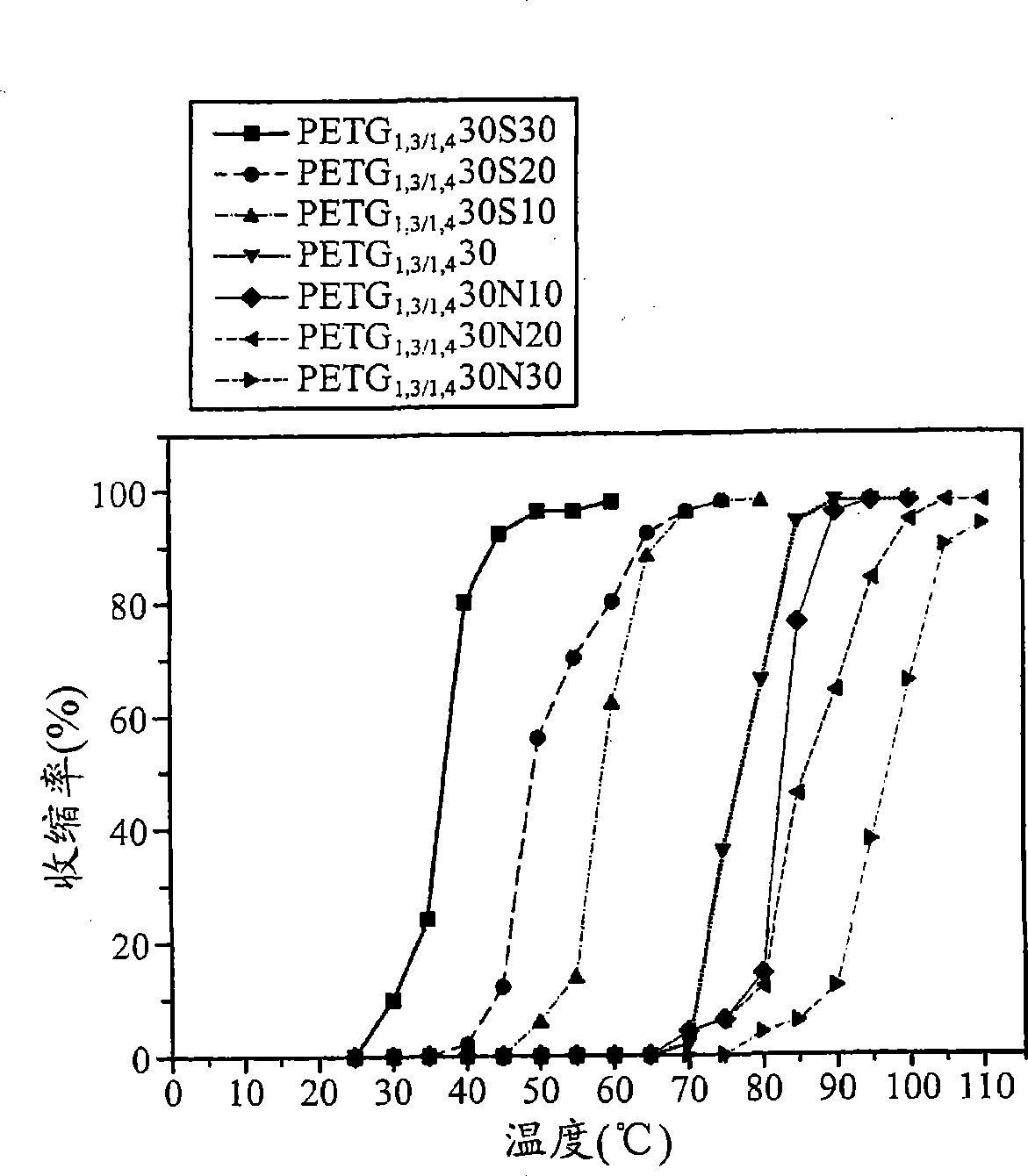

[0071] Embodiment 3, shrinkage test

[0072] Cut the amorphous copolyesters of Examples 1 and 2 into appropriate sizes, extend them at 10-20°C higher than the glass transition temperature, and double the extension ratio, and place the extended amorphous copolyesters Calculate its shrinkage in ovens at different temperatures for five minutes, which is defined as:

[0073]

[0074] l is the length of the sample after oven treatment, l 0 is the original length of the sample

[0075] refer to figure 1 , Different concentrations of succinic acid and dimethyl 2,6-naphthalene dicarboxylate can change the shrinkage temperature of the amorphous copolyesters of Examples 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com