Antibacterial additive for producing antibacterial acrylic fibre

A technology of antibacterial additives and antibacterial agents, applied in the field of antibacterial additives, can solve problems such as poor compatibility and achieve excellent performance

Active Publication Date: 2009-07-01

SINOPEC SHANGHAI PETROCHEMICAL CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

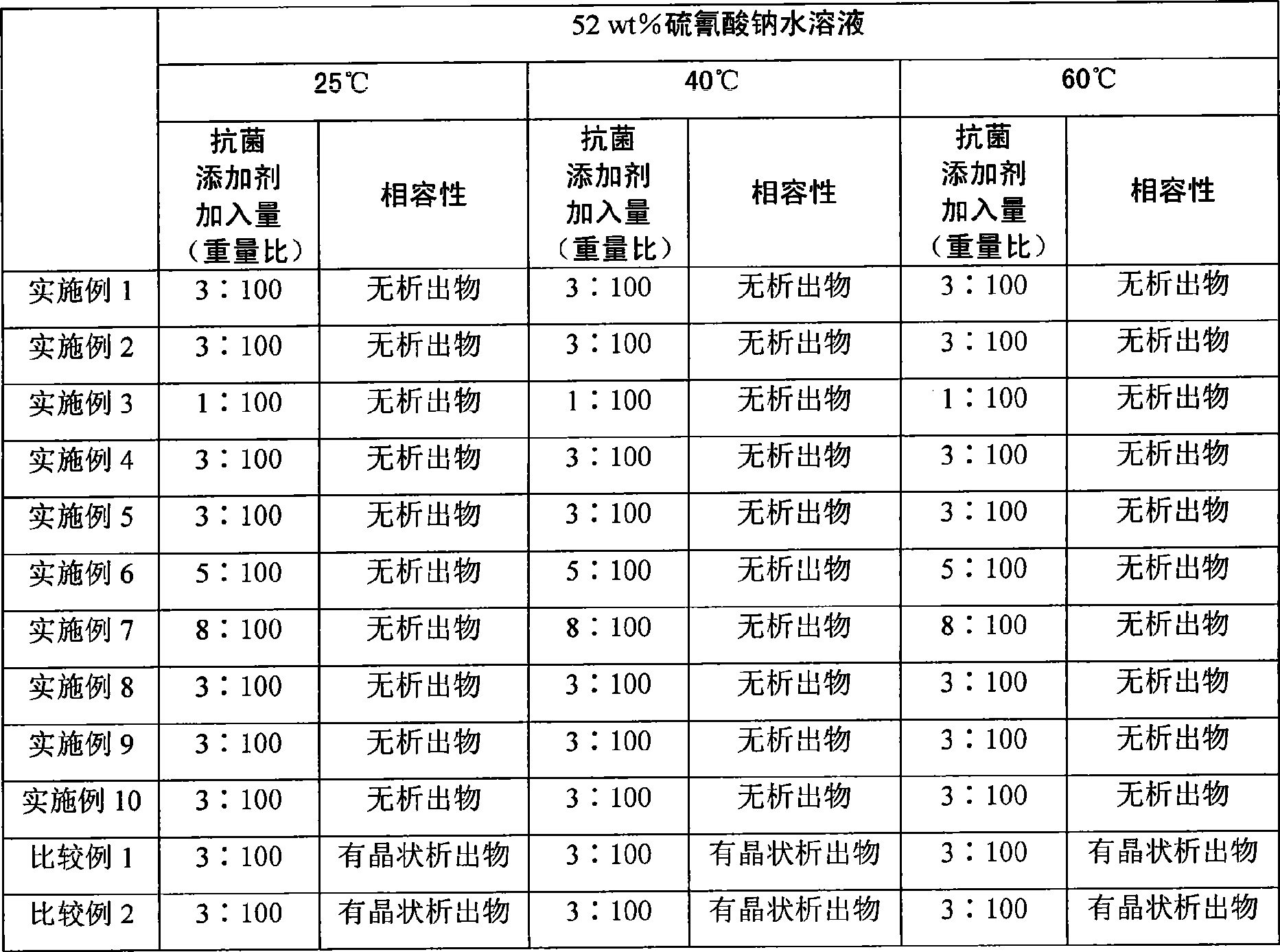

[0005] The invention provides an antibacterial additive for manufacturing antibacterial acrylic fibers, which uses organic matter such as diphenyl ether derivatives as antibacterial agents, and solves the problem of antibacterial agents and acrylic fiber spinning with sodium thiocyanate aqueous solution as a solvent. The technical problem of poor compatibility of stock solution to make up for the defects in the existing technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~10

[0018] At room temperature, uniformly mix the solubilizer and emulsifier with the solvent polyethylene glycol-400 in the required ratio, then gradually add the required amount of antibacterial agent into it under stirring, and continue to stir until the system is Clear and transparent, the antibacterial additive is prepared for use.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an antibacterial additive for producing antibacterial orlon, which is a solution and comprises an antibacterial agent, a solubilizing agent, an emulsifier and a solvent, wherein the antibacterial agent is A or a mixture of the A and B, the A is 2.4.4'-trichloro-2'-dihydroxy diphenyl ether, the B is 4-chlorine-3,5-xylenol or 2,4-dichloro-3,5-xylenol, and the weight ratio of the A to the B is 1:0-0.3; the solubilizing agent is hydrogenated castor oil polyoxyethylene ether-60; the emulsifier is one or a mixture of more than two selected from Tween-20, Tween-40, Tween-60 or Tween-80; and the solvent is polyethylene glycol-400. The weight ratio of the total amount of the solubilizing agent and the emulsifier to the antibacterial agent is 1-4:1, the weight ratio of the solubilizing agent to the emulsifier is 10:1-7, and the content of the antibacterial agent in the antibacterial additive is 5 to 30 weight percent. Compared with an orlon spinning solution taking sodium thiocyanate aqueous solution as the solvent, the antibacterial additive has better solubility.

Description

technical field [0001] The invention relates to an antibacterial additive, in particular to an antibacterial additive used to manufacture antibacterial acrylic fiber by using a sodium thiocyanate aqueous solution as a spinning solvent through a wet spinning process. Background technique [0002] In recent years, while people are pursuing the comfort of chemical fiber fabrics, they also pay more and more attention to the health care functions of fabrics. Among them, antibacterial fabrics with bactericidal or antibacterial functions are very popular, such as antibacterial underwear and antibacterial socks. Antibacterial fabrics are usually made of antibacterial functional fibers with antibacterial properties. Acrylic fibers have good warmth retention and moisture permeability, and are easy to blend with wool and cotton. They are suitable for making underwear, socks and other close-fitting fabrics. Therefore, antibacterial acrylic fibers are very The development of ideal antiba...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01F6/54D01F1/10

Inventor 马正升陈健章毅赵正然沈志明杨美文严国良黄翔宇

Owner SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com