External valve type hydraulic self-sealing plunger oil-well pump

An external oil well pump technology, applied in variable capacity pump components, pumps, pump components, etc., can solve problems such as complex operations, low efficiency, and large friction of plunger pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

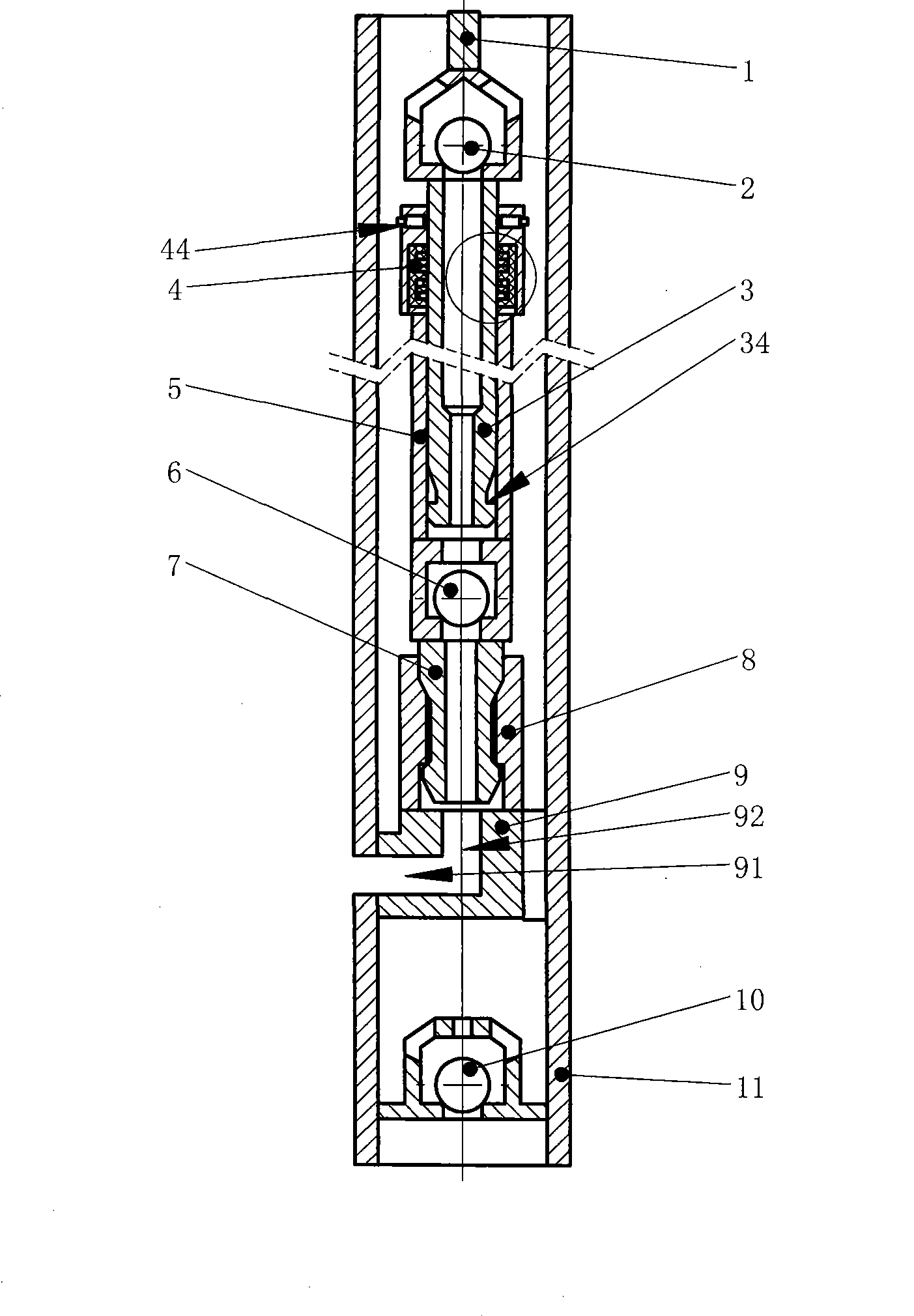

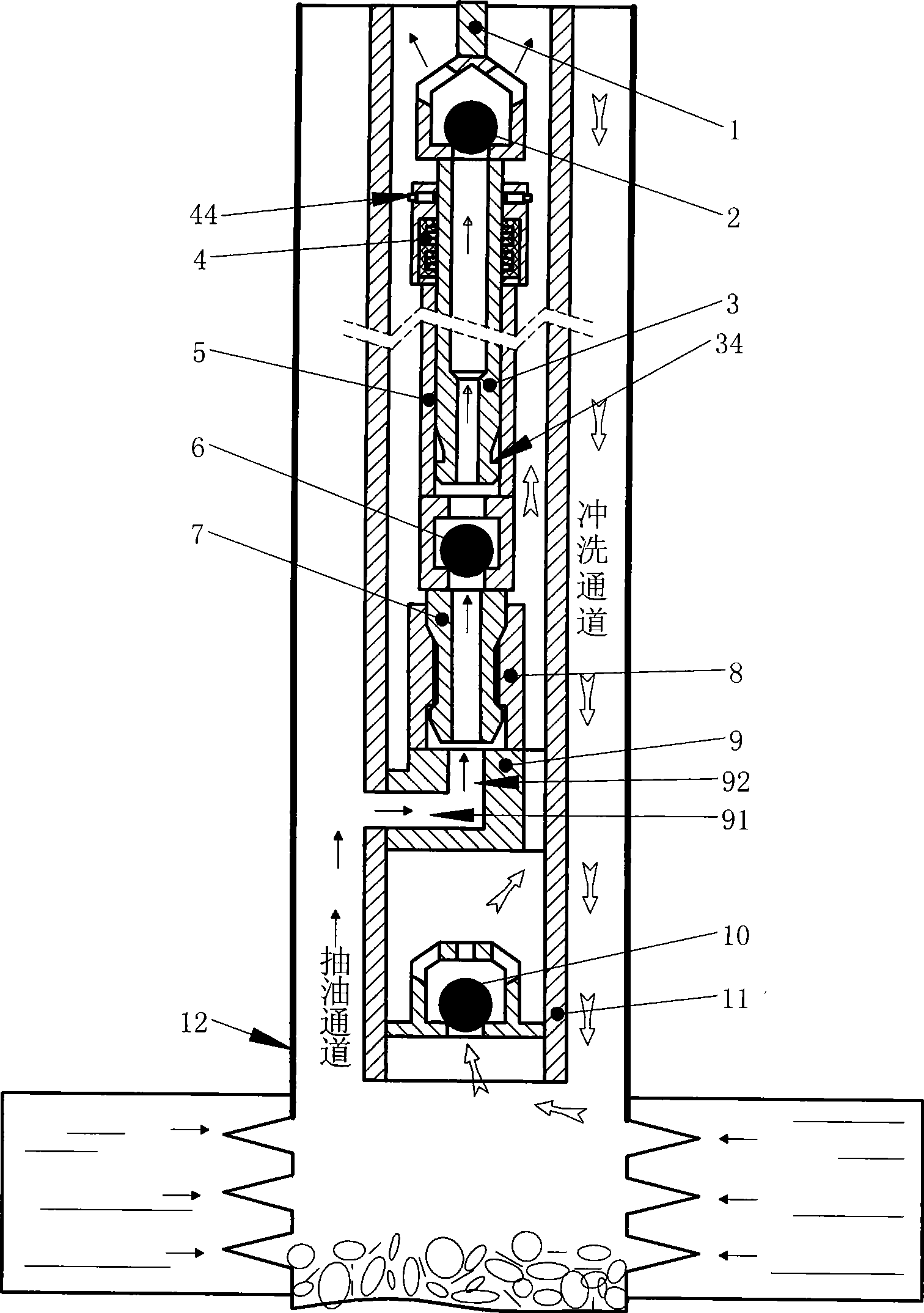

[0016] Depend on figure 1 As shown, similar to the existing oil well pump, the valve external hydraulic self-sealing plunger oil well pump of the present invention is sequentially equipped with a sucker rod 1, a floating valve 2 and a plunger 3 placed in the pump barrel 5 from top to bottom. ;Different from existing oil well pumps:

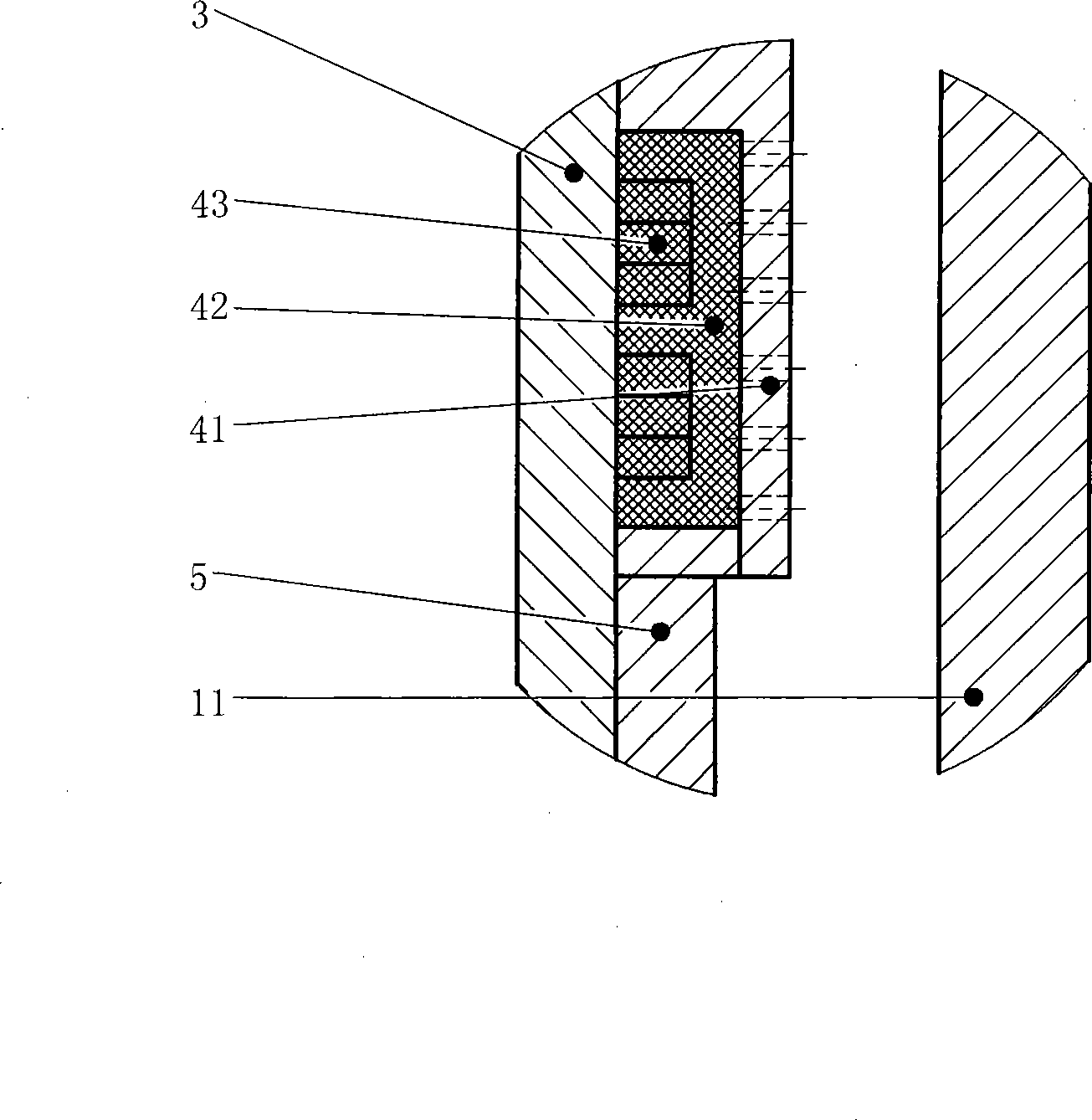

[0017] The upper part of the pump barrel 5 is provided with a sealing section 4, and the lower part is fixedly connected with a fixed valve 6 and a fixed locking support 7. 6 interlinked channels;

[0018] The lower end of the locking support seat 8 is fixedly connected with a sub-cavity bridging joint 9, the sub-cavity bridging joint 9 has a horizontal hole 91 and a vertical hole 92 communicating with each other, and the vertical hole 92 communicates with the passage in the middle of the fixed locking support 7;

[0019] Set an outer pipe 11 as a flushing pipe or an oil pipe, the outer pipe 11 is sleeved outside the above-mentioned components, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com