Speed variator

A technology of transmission and clutch, applied in the direction of vehicle gearbox, gear transmission, transmission element, etc., can solve the problems of insufficient compactness, lengthening power transmission route, affecting automobile fuel consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

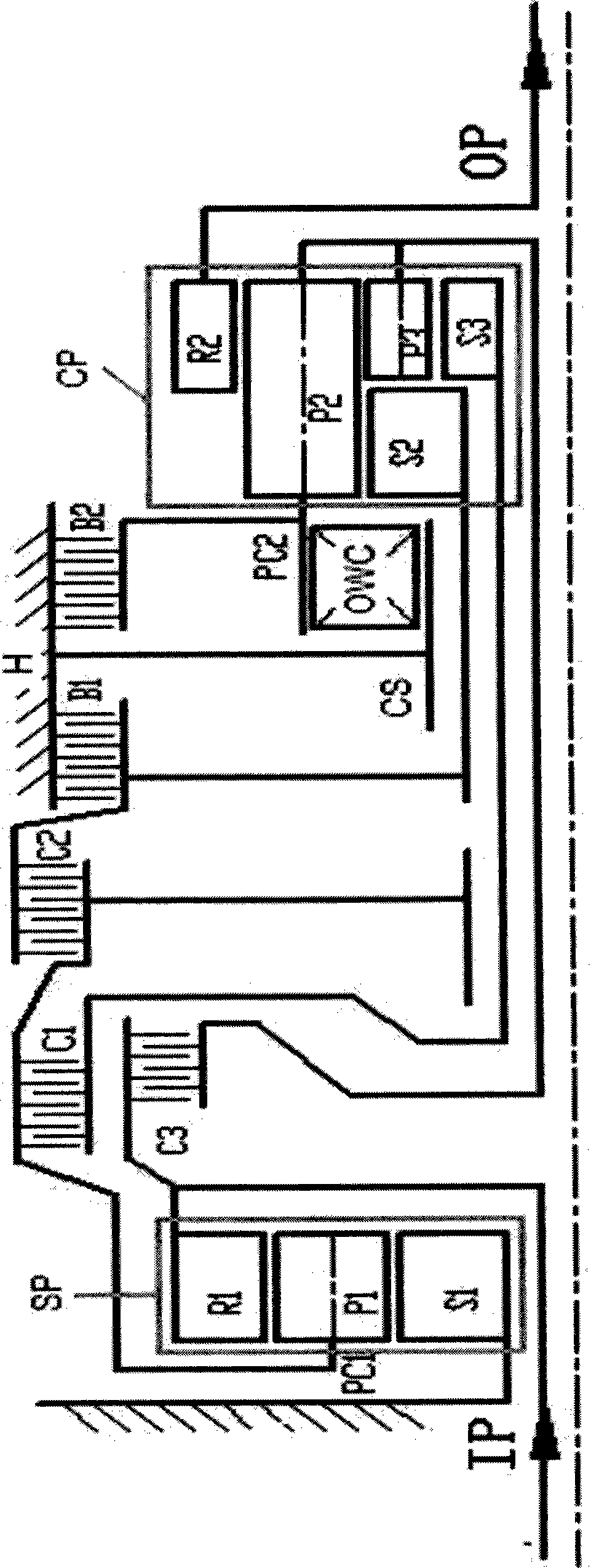

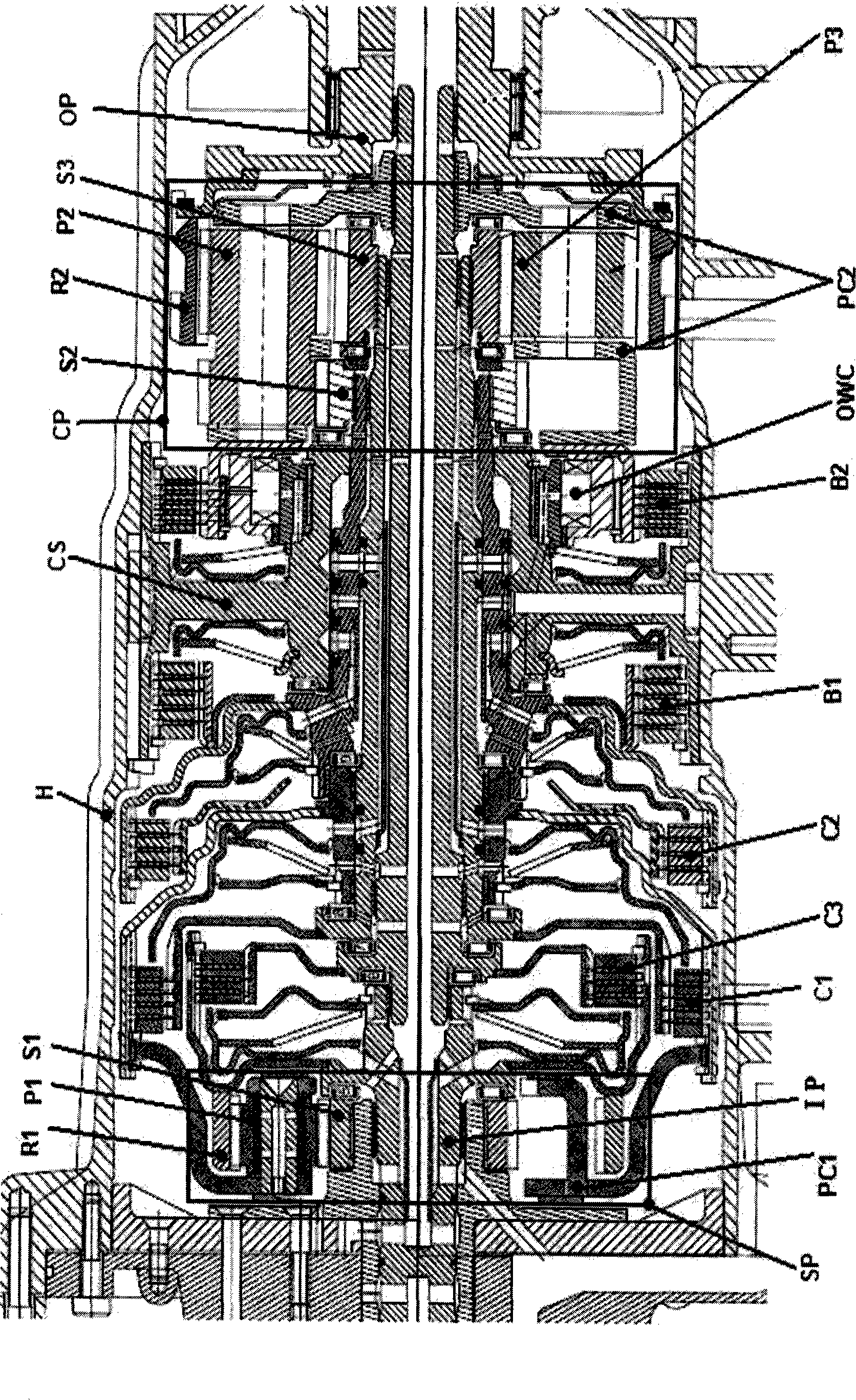

[0038] Such as figure 1 Shown, in the automobile automatic transmission that the present invention introduces, comprise altogether a power input shaft (IP), a power output shaft (OP), a single-row planetary gear set (SP), a compound planetary gear set (CP) , five multi-plate friction shifting components (three clutches and two brakes), a one-way clutch (OWC), an intermediate support (CS) and the transmission housing (H). The power input shaft (IP) passes through and is coaxial with the single row planetary gear set (SP). The power take-off shaft (OP) is arranged behind and coaxially with the compound planetary gear set (CP).

[0039] Depend on figure 1 It can be seen that in this transmission, the single planetary gear set (SP) is arranged in front of the compound planetary gear set (CP). There is no clutch in the front and periphery of the single row planetary gear set, and all shifting parts are all positioned between the single row planetary gear set and the compound pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com