Low-pressure gas discharge lamp

A technology for low-pressure gas and discharge lamps, which can be applied to parts, luminescent materials, chemical instruments and methods of gas discharge lamps, and can solve problems such as motion artifacts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

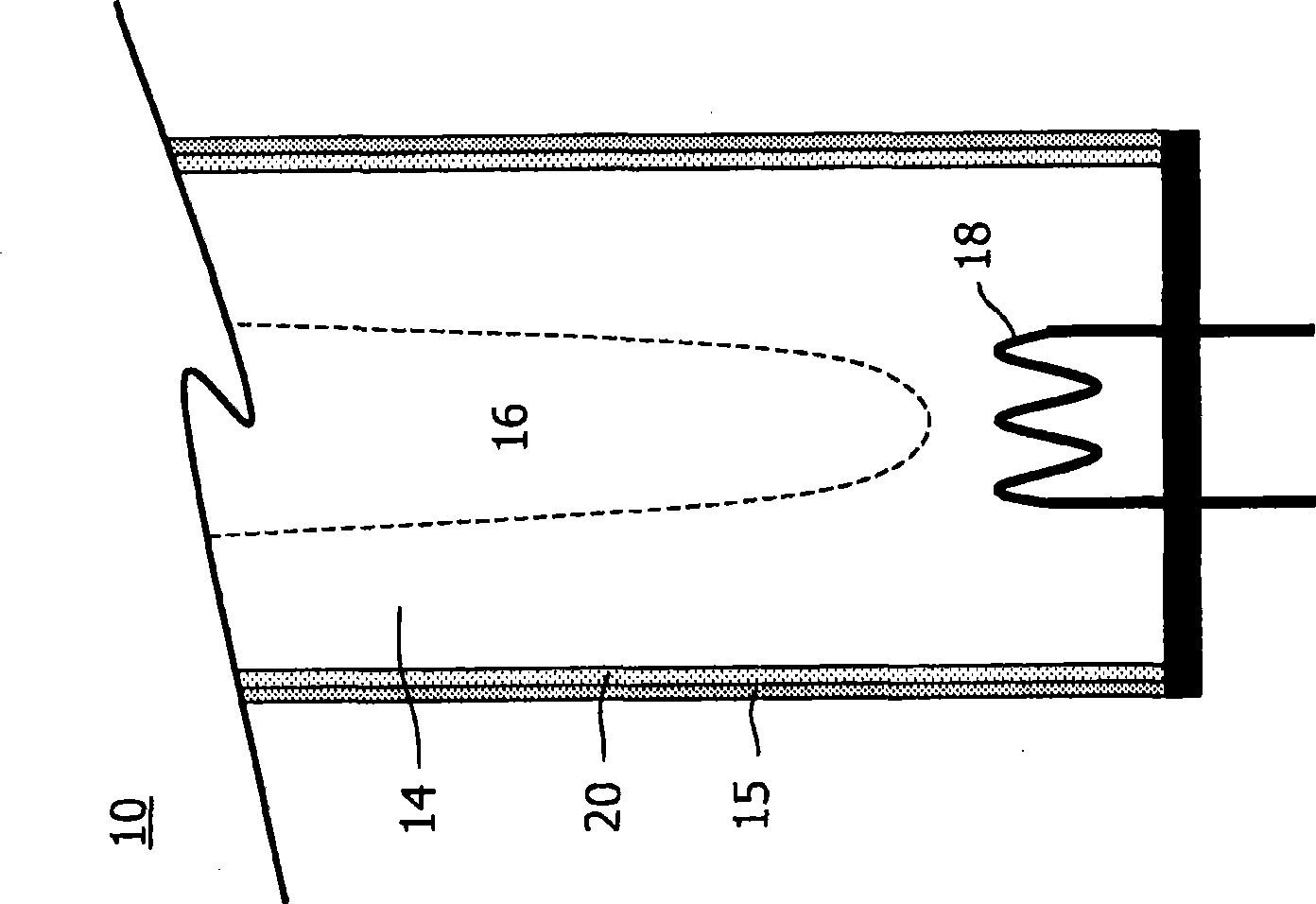

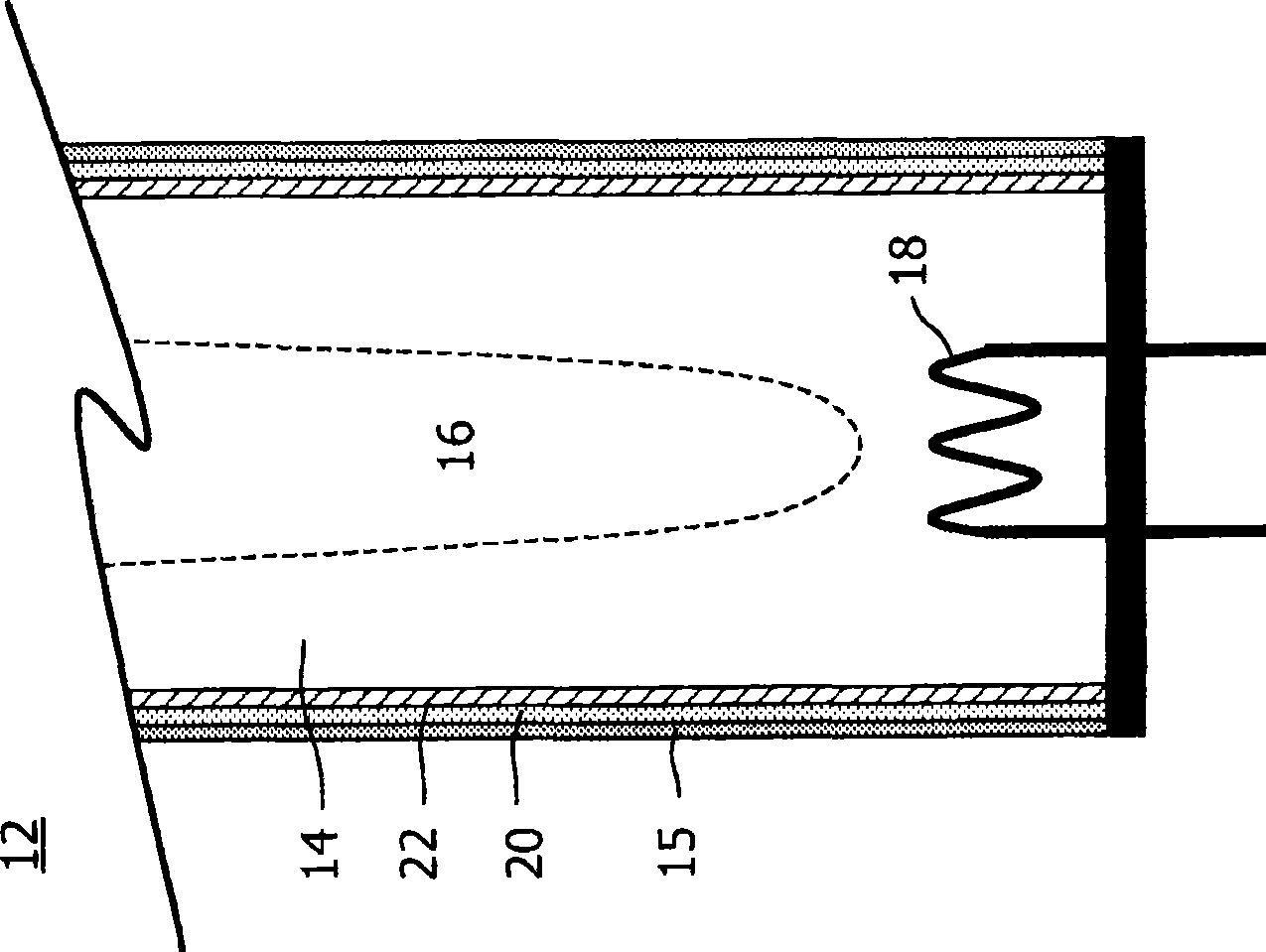

[0029] Figure 1A with 1B A cross-sectional view of a low-pressure gas discharge lamp 10, 12 according to the invention is shown. The low-pressure gas discharge lamp 10, 12 according to the invention comprises a light-transmissive discharge vessel 14, which seals off a discharge space 16 in a gas-tight manner. The discharge space 16 includes a gas filling, which includes, for example, metal compounds and buffer gases. The low-pressure gas discharge lamp 10, 12 further comprises a coupling element. The coupling element couples energy into the discharge space 16 , for example via capacitive coupling, inductive coupling, microwave coupling or via the electrodes 18 , in order to effect a gas discharge in the discharge space 16 . The discharge vessel 14 comprises a wall 15 having a luminescent layer 20 comprising a luminescent material. The luminescent material absorbs, for example, ultraviolet light emitted by the discharge and, for example, converts the absorbed ultraviolet li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com