Light guide plate, light guide plate assembly, and surface illuminating device and liquid crystal display device using these

A technology of a light guide plate and an assembly body, which is applied to display devices, lighting devices, and illuminated signs, etc., can solve the problems of difficulty in thinning and large-scale, difficulty in obtaining high-brightness illumination light, and limited incident light amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The light guide plate, the light guide plate assembly, the planar lighting device and the liquid crystal display device using them of the present invention will be described in detail below based on preferred embodiments shown in the drawings.

[0095] First, the light guide plate assembly of the first aspect of the present invention, the planar lighting device of the second aspect of the present invention using it, and the liquid crystal display device of the fifth aspect of the present invention will be described with reference to FIGS. 1(A) to 17 .

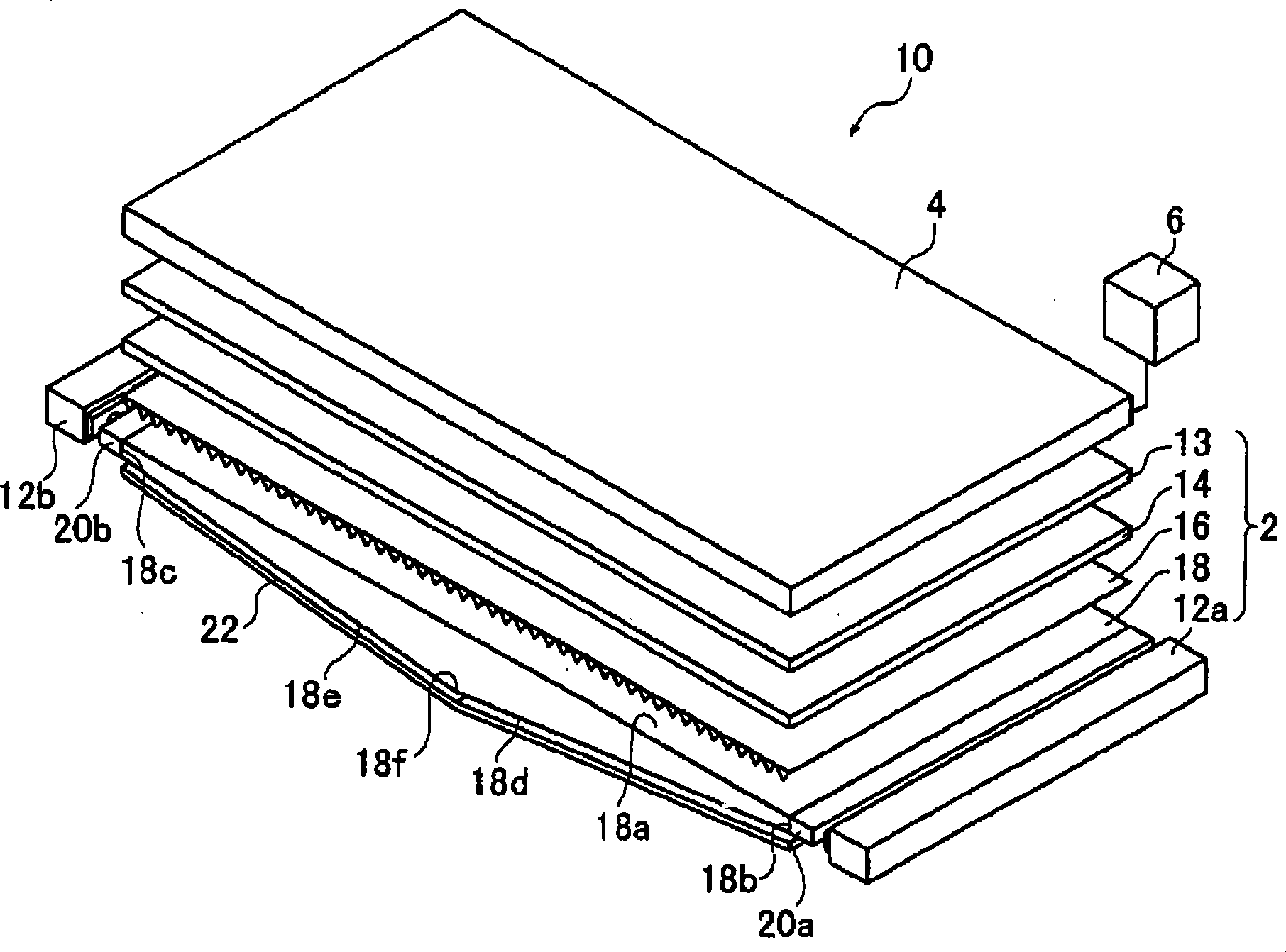

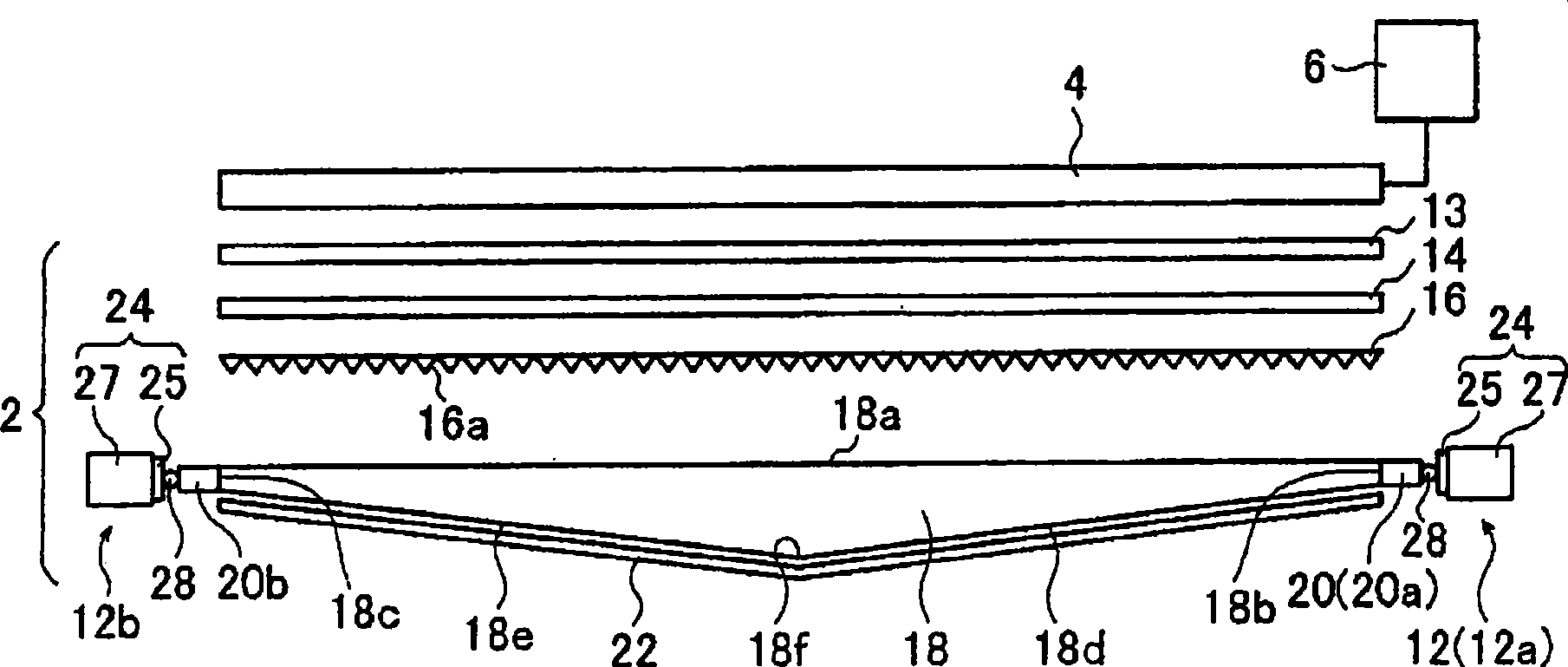

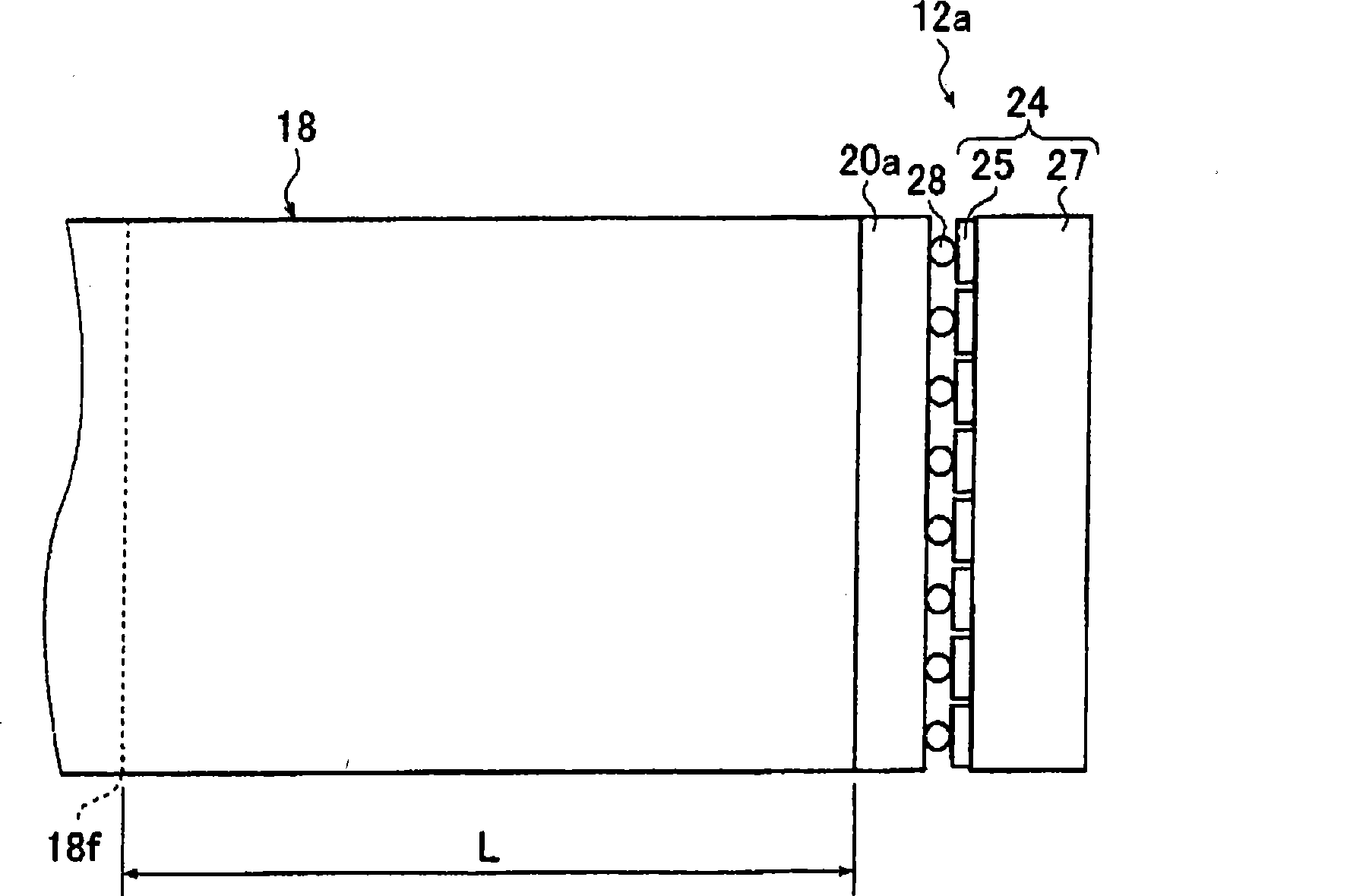

[0096] FIG. 1(A) is a schematic perspective view showing an embodiment of a liquid crystal display device equipped with an embodiment of a planar lighting device utilizing an embodiment of the light guide plate assembly of the present invention, and FIG. (A) is a schematic cross-sectional view of a liquid crystal display device. And Fig. 2 (A) is a schematic partial top view of a light guide plate and a light source used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com