Laser cleaning system and method thereof

A laser cleaning and laser technology, which is applied in the field of cleaning systems, can solve the problems of increasing staff troubles, time, and a large number of probes, and achieve the effect of reducing manpower and time resources and improving decontamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Relevant detailed description and technical contents of the present invention, now cooperate with accompanying drawing to illustrate as follows:

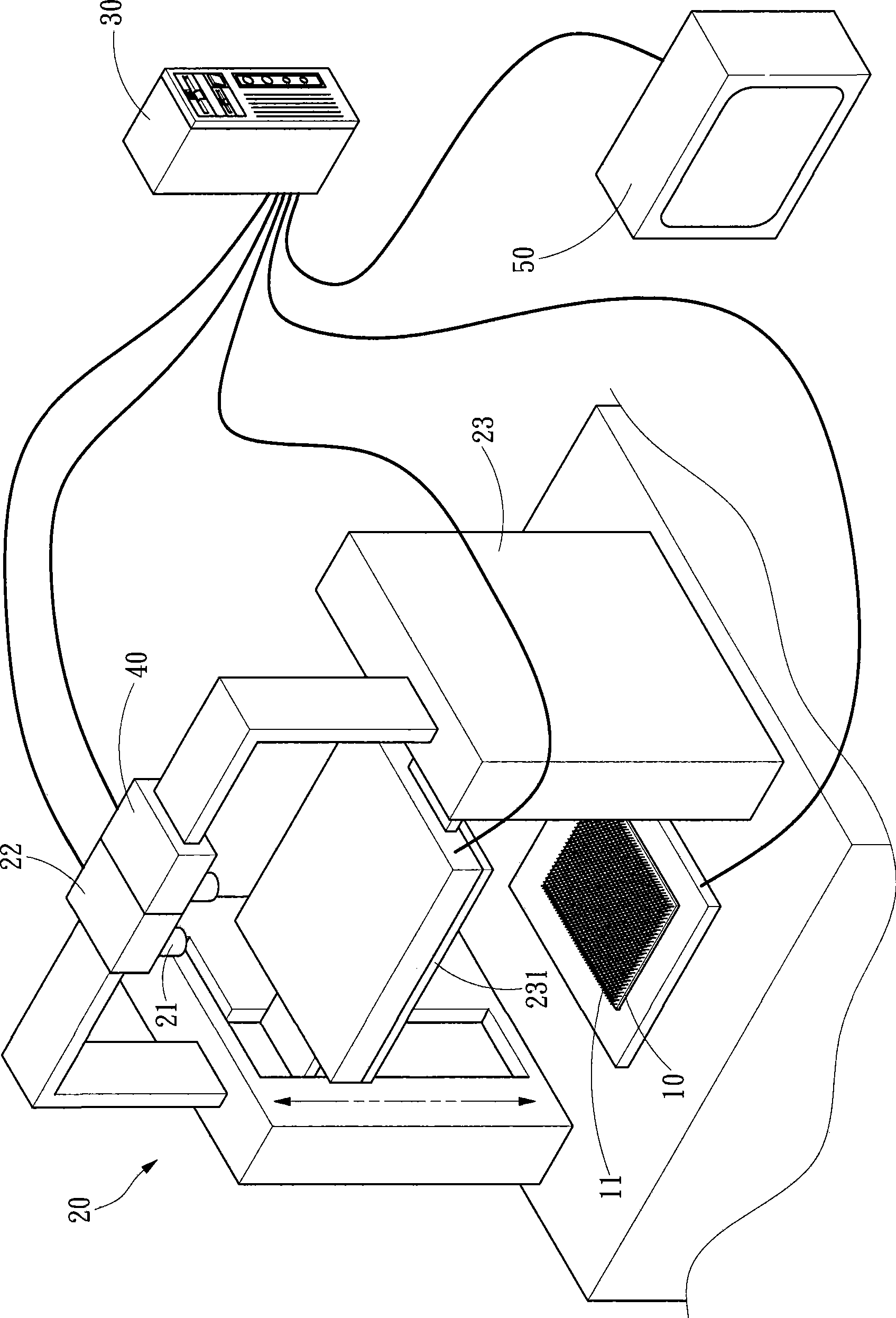

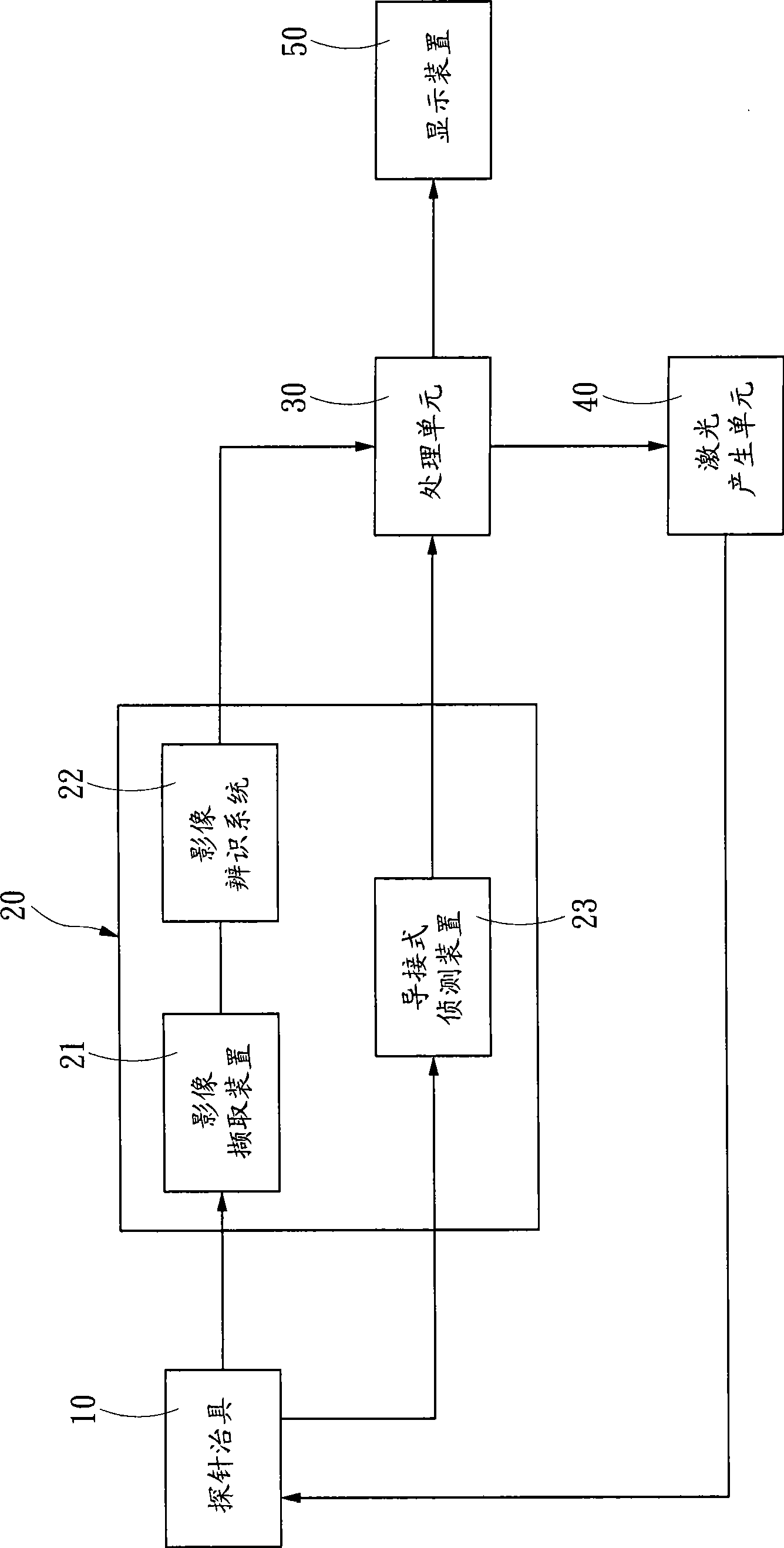

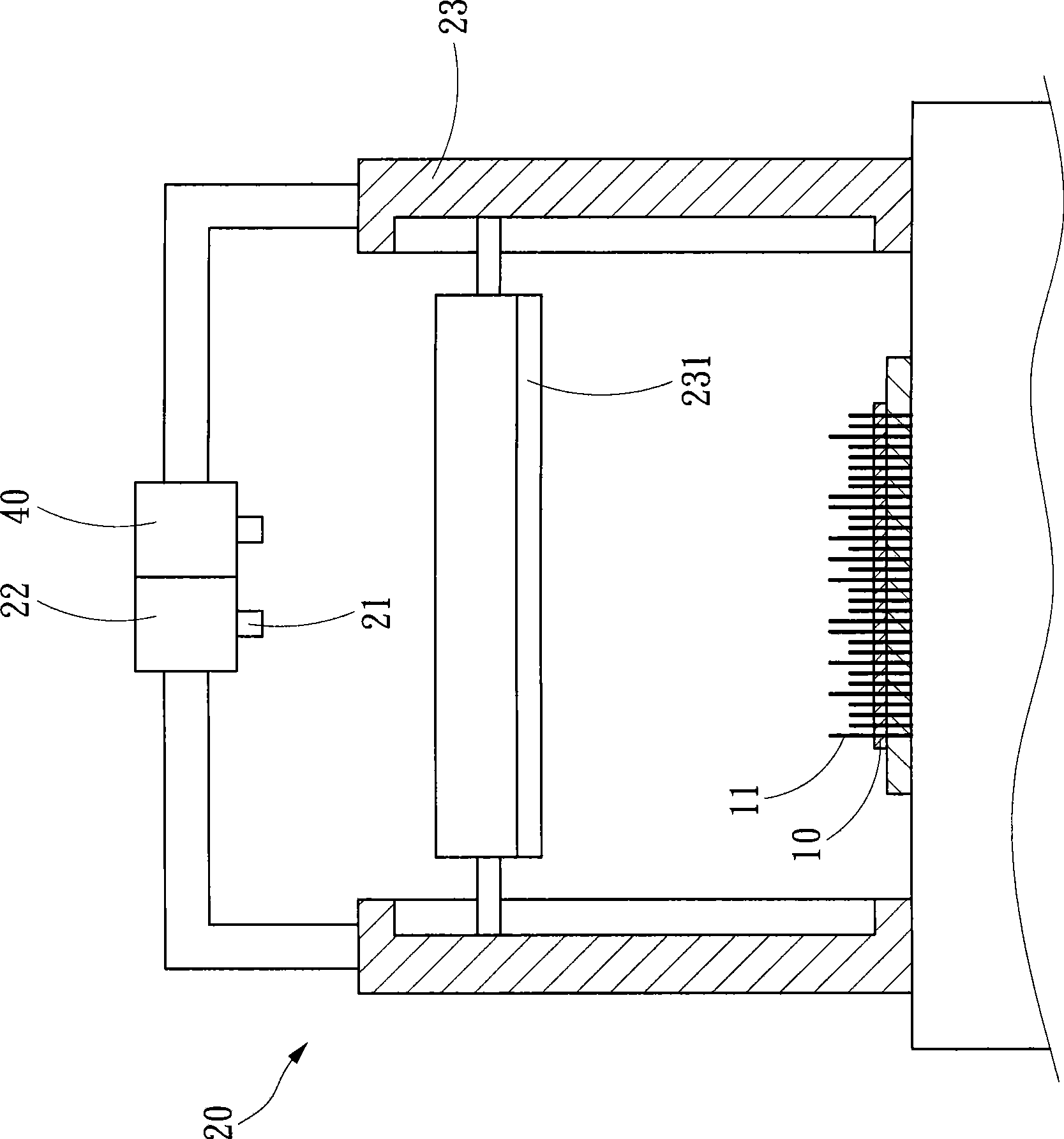

[0018] see figure 1 and figure 2 As shown, it is a schematic diagram of the overall three-dimensional appearance and the basic structure of a preferred embodiment of the present invention. As shown in the figure: the present invention relates to a laser cleaning system, which is applied to the removal of dirt from the probe 11 on the probe fixture 10. The probe fixture 1 is provided with a plurality of probes 11 for circuit detection. The laser cleaning system includes an identification unit 20, a processing unit 30 connected to the identification unit 20, and at least one subject to the processing unit 30. Driven laser generating unit 40, the identification unit 20 is erected at the corresponding position of the probe fixture 10 to identify at least one probe 11 to be cleaned on the probe fixture 10, and obtain a pair of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com